ANS Annual Meeting Dresden Station technical tour

When I was registering for the various events scheduled to take place during the ANS Annual Meeting this past June, I was quite excited to see that one of the three technical tours would be at Exelon's Dresden Nuclear Station, not too far from downtown Chicago where the meeting was taking place. Luckily, I made the cut for attendance and was issued a ticket for the tour when I checked in at the meeting desk.

The transportation for the tour was a comfortable, air-conditioned motor coach-which was good, because Illinois was in the midst of a heat wave. The ride to Dresden was quicker than I'd expected, given the distance. Those of us who hadn't been there before were looking out of the windows all the time to see the first hint of the tall stacks, or perhaps the spherical containment for the now shut down Dresden Unit 1.

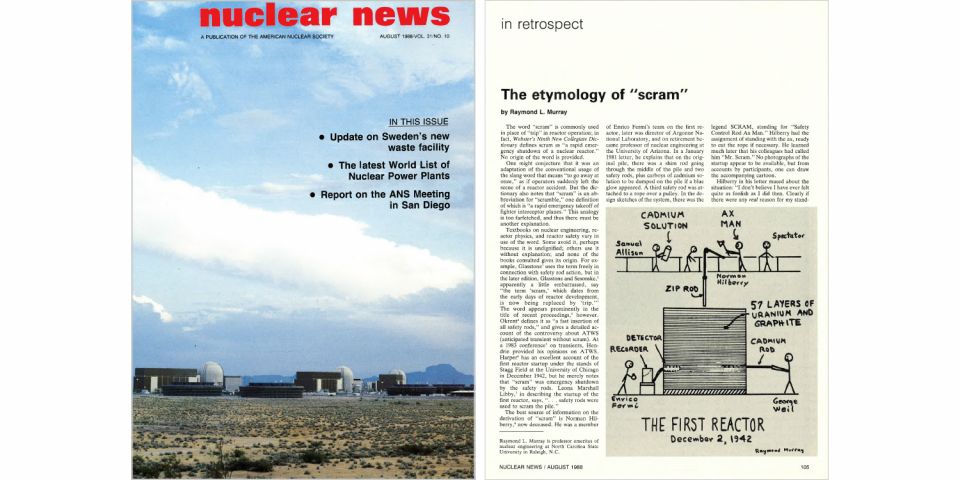

Permit a digression at this point; the aforementioned structure, which is a steel sphere 180 feet in diameter, is one of those "nuclear relics" of some note that we have in this industry. Spherical containment didn't last too long in commercial nuclear plant construction before giving way to far easier to build (and less expensive) cylindrical containment buildings. Seeing a photo or drawing of a spherical containment building immediately brings to mind the early days of nuclear energy; structures like this are the pyramids of our field. (Note: They are less permanent, though-a number of them have been completely dismantled and removed at other sites.) This would be my chance to check off No. 2 on my list of viewing such containment buildings; I say No. 2 because I formerly walked daily past the only larger one, at the Kesselring Site in New York. Not far below this in rank in terms of "nuclear archaeology," if you will, is the fact that Dresden-1 was the nation's first privately financed commercial nuclear plant. All of these reasons make Dresden Station a top priority for those of us with an interest in preserving a record of our nuclear history. In fact, the American Nuclear Society has designated Dresden Unit 1 as a Nuclear Historic Landmark.

When the bus arrived at the station, I noticed something immediately that I had not noticed before in photos: The newer Dresden 2 and 3 units were built immediately adjacent to the Dresden-1 turbine building-and in fact the buildings abut and connect. Dresden-2 and -3 are later model GE boiling water reactor/3 reactors in Mark I containment buildings. The sight of the plant is thus a mixture of the old, or should I say original, and the more modern at once. Both units 2 and 3 were running at full power that day; the load on the grid from the heat wave was making the news.

After an orientation and welcome, along with issuance of dosimetry and a few questions, we were divided into groups of not more than five persons each; each group would have one or two escorts for security purposes who also doubled as our tour guides. My "group" as it were had only two members; our escort was Marisa Seloover, a young electrical engineer who acts as the plant's systems engineer for compressor equipment. Marisa immediately showed her enthusiasm for her job, and was extremely informative and helpful at all times. In fact, everyone at the plant was extremely willing to tell us information and describe operations at the plant, as well as explain equipment.

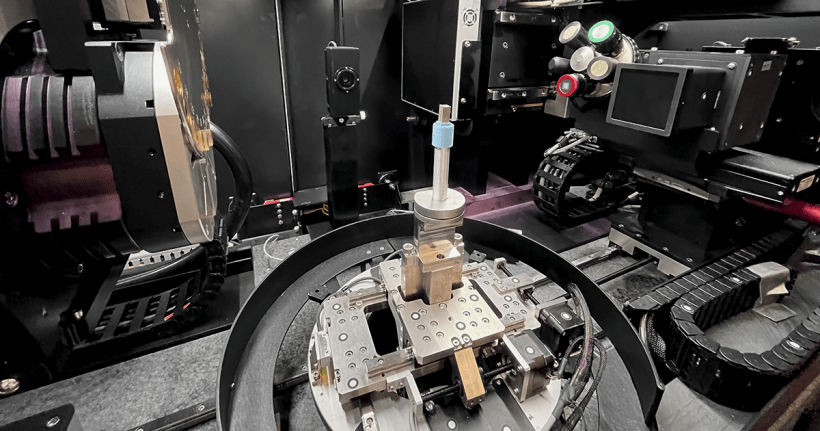

The tour overall had to be cut a bit short, because the time was cramped and also because the temperature outside was about 102 °F that day. We toured a good portion of the operating plants, although since this was a BWR plant, close access to the turbine generators wasn't allowed. We looked at control rod drive equipment, the access doors to the drywells, various pumps, and various labyrinthine spaces around the reactor buildings. We got a chance to stand on the refueling floor and look right down into the spent-fuel pool for Unit 3; yellow-clad workers were up on a ladder in the distance. The volume of the space was more impressive than I'd pictured it; the refueling floor level spans both reactors.

A fun moment of the tour occurred when we stopped next to one of the feed pump rooms. One of the escorts managed to yell to us over the din that the pump room held three electric feed pumps, each of roughly 7000 horsepower, and that much of the noise we'd heard outside the plant was actually the cooling air for these pump motors. He indicated that hearing was practically impossible if the access door were open; then he opened the door. He was correct. And yes, of course, we were wearing hearing protection, hard hats, and safety glasses issued by Exelon before leaving the training building outside the plants.

I myself had reserved a special enthusiasm for seeing Dresden-1, and we walked through the turbine hall of Unit 2 to an access door and immediately were in the turbine building of Unit 1. The turbine generator and associated equipment are long gone; the building is now used primarily for tool storage and maintenance work. As we walked along a level that would originally have been well above the turbine generator, I looked down and thought of the old photos I'd seen of when the plant was operating.

Then, we went through a door and into the spherical containment itself. One of our escorts immediately yelled-and the echo, which he knew he would get, made all of us laugh. We were on a level above that of the steam generators, which he said were below the flooring (remember that Dresden-1 was a dual-cycle BWR with both direct steam to the turbine generator and four steam generators that fed steam to it as well.) The height of the concrete structure rising block-like in front of us, which formerly contained the steam and water piping and on top of which was the central steam separator drum, was quite impressive. We walked around to our left and could see the opening in the center of this structure that essentially amounted to the refueling space-below the steam drum, and between the steam risers. I quickly imagined that this would have been entirely an exclusion zone when the reactor was operating. The emptiness of the rest of the structure, with few signs of equipment, made the area feel less like a nuclear power plant and more like some sort of test mockup, which of course it was not. As we left the sphere, I recalled that the original design plan included not only the turbine generator but the control room as well inside the sphere; GE and Bechtel eventually changed their minds about that.

After we returned to the training center, we were given water to drink because of the heat (we'd skipped the tour of the dry cask storage areas because of that factor) and got the chance to talk to our guides for a few moments. Marisa noted that Unit 2 had been upgraded over the years, and was rated about 960 MWe-although on that day, because of ambient temperatures being so high, the plant was limited to about 950 MWe. Unit 3 was at its full rated power of about 912 MWe; it had not received all of the upgrades yet that Unit 2 had (main generator rewind, new low pressure turbines and turbine casings, new and much more modern recirculation pump drives) but would receive the last of them during the next refueling.

She explained how tight the limits were on water that the plant can discharge to the rivers, and how the plant uses a combination of river water, cooling lake, and added cooling towers to meet thermal discharge limit requirements. Her descriptions of practice drills and events for the plant were very helpful and informative. She, and others like her, struck me as the bright hope for the future in the nuclear energy industry.

After this, it was time to complete the day's events with brief tours of the control room simulator, and a presentation on the plant, its history, and its operation given by Work Management Director Joe Sipek. The control room tour was extremely informative; the personnel there answered all of our questions fully and clearly. The tour was very thorough, even including the alley behind the main panels and descriptions of how the simulator functions, as well as how the staff rotates through.

After Mr. Sipek's presentation and some souvenir Dresden Station pens were handed out, it was time to get on the bus and leave for Chicago and our comfortable hotel. This was the final event for the whole annual meeting for me; I'd be flying home the next day. On the way in, I'd looked at the site and wondered about very many things-mostly about what I'd find inside, what I'd see. On the way out, I thought mainly about the people I'd met and how well they'd impressed me. Of course it goes without saying that any plant is primarily its people, and Exelon left this writer with an impression of a well-motivated, well-engaged, dedicated workforce.

All in all, as the bus made the journey down the access road out of the plant, I knew that my lasting impression would be not of things like structures that would someday be dismantled, but instead would be of the people who work and pass their knowledge on to others. It's no overstatement to say that the time invested in the trip paid me great dividends.

I'd like to thank the following people from Exelon who helped make the trip possible: Natalie Zaczek, Paul Bembnister, Scott Ackerman, Joe Sipek, Marisa Seloover, Dan Murphy, Tom Mohr, Kyle Cook, Samantha Cosenza, Nick Oudin, and Marie Frese. Also, thanks to Robert Osgood of Exelon who handled pre-trip security and communications. Any omissions from this list are my error and I offer my apologies for any such.

__________________________

Davis

Will Davis is the author of the nuclear energy blog "Atomic Power Review," and is a member of the American Nuclear Society. A former US Navy reactor operator, Davis finds his calling to be presenting the public with information about nuclear energy technology and its history.