Nuclear Matinee: Plant Vogtle Nuclear Construction Update

Last week at the ANS Nuclear Cafe Matinee we caught up with the latest milestones in nuclear construction going on at the V.C. Summer site in South Carolina. Now, let's take a look at history in the making at Plant Vogtle in Burke County, Georgia, where construction of two new AP1000 reactors is quickly moving onward and upward. How in the world do you make a nuclear power plant? Watch, and find out.

Joe Washington

From high above the site of the rebirth of nuclear energy in America, Georgia Power's Plant Vogtle project is now one-third complete!

And major milestones continue to be reached here beginning with the placement of the first nuclear island concrete on Unit 3 to create the six-foot-thick basemat. This is the foundation for the nuclear island which includes the containment and auxiliary buildings.

The placement of this basemat concrete is very significant because it precedes the setting of major components inside the nuclear island.

The basemat covers eleven hundred tons of steel rebar. It requires 6,850 yards of concrete to cover this area 254 feet long, and 161 feet across at its widest section.

This is not just any concrete. It's nuclear grade concrete, which means that it has passed rigorous methods of qualifying and manufacturing. It's specially designed, mixed, reinforced and constructed according to strict procedures. It requires a trained workforce with special certifications to perform this activity.

The planning for this process was so stringent that a mock site was built to simulate this concrete placement before it actually took place. Months of planning and detailed preparation were keys to the success of this significant event.

In fact, many of the construction activities here undergo a trial-run on scaled down mock sites to ensure everything is done with precision when it's time to perform the actual task. This is one of many examples of Georgia Power's unconditional commitment to safety in preparation for all activities here.

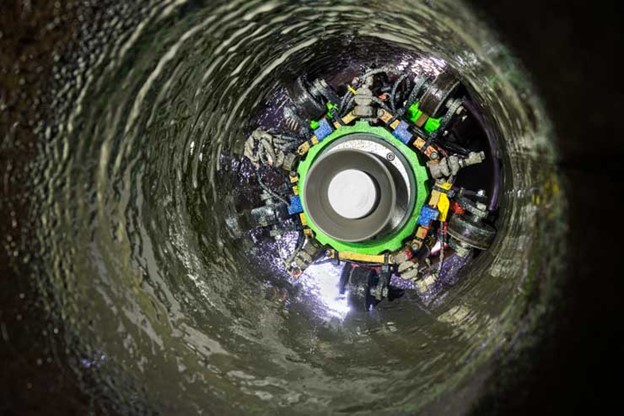

With the completion of the basemat for Unit 3, the cradle that will hold the bottom head of the Unit 3 containment vessel was recently placed inside the nuclear island. David Keech has the details on this landmark achievement.

David Keech

CR10 is the first major module to be set in place here at the site and is the first installed heavy lift. The safety processes and planning used to design the rigging have been going on for months. A lot of upfront work was performed to ensure everything was where it was supposed to be and the lift was performed safely. In order to move a structure like that it actually takes a rigging plan that's above and beyond even the containment vessels. The weight had to be equalized to ensure there was no undo stress put on the individual structural members as it was being lifted, swung and set. Currently the CR10 is being anchored to the concrete foundation. Once that is complete, additional rebar and concrete will be installed to get ready to set the Unit 3 containment vessel bottom head onto CR10.

Joe Washington

Thanks David. Elsewhere on the site permanent buildings and structures are sprouting up, and we can begin to really comprehend the magnitude of this project.

There's a great deal of activity around the cooling towers. The first x-braces, sometimes called the "legs," are being put in place at a rate of one per day. This marks the erection of the first above-ground permanent structures here.

Other permanent buildings going up that will eventually be shared by all four Vogtle units are for maintenance, security, operations offices, and support functions. These will make up this inner area known around here as the "central campus."

These new permanent buildings will one day replace the office complexes where Georgia Power, Westinghouse, Southern Nuclear, CB&I and other employees are currently located. And the modular assembly building, as well as other temporary structures, will all be removed once the project is complete.

Across the footprint the laydown yards are expanding as components arrive. And as you can see, many of them are absolutely enormous!

Like these 79 foot moisture separator reheaters for the unit 3 turbine building. Their function is to increase the temperature of the steam and remove water droplets from it before it reaches the turbine. These arrived by train, then were lifted onto crawlers and moved to storage where they will remain until time to be installed.

Another huge component that arrived recently is the deaerator for Unit 3. Its function is to eliminate dissolved gases, such as oxygen, from feedwater. This prevents corrosion and helps reduce plant maintenance and operating costs. The gigantic device was shipped to Savannah, Georgia from Korea, then offloaded to this oversized-load transporter and brought here. This was a major operation, and strategic deliveries like this will be repeated many times over during the course of construction. Here's Herman Richards with details.

Herman Richards

The successful delivery of the Unit 3 deaerator at the Vogtle site was the result of a well executed detailed plan. This major undertaking was coordinated by Westinghouse and was a collaborative effort between our consortium partners, their contractors, local communities, local and state agencies, Southern Nuclear and Georgia Power.

George McDonough

Moving an object of this size across the highway really turns out to be extremely complicated. It had a push and pull support on it. You just can't pull it and just can't push it. So we had to make sure that we got everything coordinated, all the permits in place, and we probably ran this route ten times at least to make sure that everything was done properly. There were signs up, the public was notified - that was all coordinated through the law enforcement divisions and through the DOT. And it's just amazing to see something that large moving down the highway. Probably the greatest part of it was to see little kids lined up beside the road waving American flags as you came through; the support from all of the people, the community. It was just overwhelming.

Joe Washington

Thanks George. Hundreds of components will continue to arrive as work progresses steadily on the nuclear islands and turbine islands for Units 3 and 4. Most significant is the recent arrival of the reactor vessel for Unit 3, traveling by ship and train from South Korea.

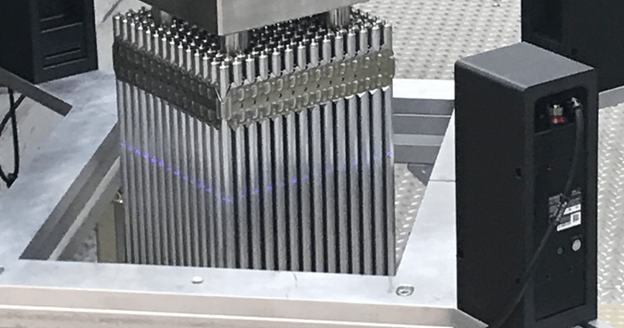

Right now two of the three middle rings of the Unit 3 containment vessel are being assembled.

The openings you see here, called penetrations, range in size from one-half inch to sixteen feet in diameter and allow for everything from cables and pipes to be installed, to small cranes that go inside the containment vessels during routine refueling and maintenance.

When complete, the two containment vessels will be moved to the nuclear islands for placement and welding in place. Each one will weigh 4,000 tons and measure 130 feet thick and 215 feet tall.

Chicago Bridge and Iron is fabricating the containment vessels and the cradles, as well as designing and building many other parts of this overall project. Recently, CB&I acquired the Shaw Group, which has been the construction partner here since the beginning of the project. Renita Crawford tells us more about the acquisition.

Renita Crawford

The combination of CB&I and Shaw has created one of the world's largest engineering, procurement and construction companies focused on the global energy industry. And although our companies target their expertise toward different end markets, the skills of the employees are transferable throughout the entire combined organization. Now with approximately 50,000 employees CB&I is able to provide our clients with a wide range of products and services across the entire energy spectrum. There are a lot of exciting changes here at the site. The new company will market as CB&I using the CB&I logo, and if you look around you will see the CB&I logo is very visible on vehicles, most of our equipment and on our structures. The CB&I flag is also flying at our entrance.

Joe Washington

Thanks Renita. CB&I has built three fourths of the nuclear containment vessels currently operating in the United States.

As we move through this historic venture, paving the way for the rebirth of nuclear energy in this country, our uncompromising focus remains on safety and quality. Our customers expect and deserve a safe, reliable and clean source of energy, and it's our mission and goal to provide it to them.

Georgia Power's priority on safety and quality is one of many reasons our parent company, Southern Company, was selected as the 2012 Electric Utility of the Year by Electric Light and Power magazine. That's all from here for now. We hope you'll join us again for the next Vogtle Timeline!

Thanks to Georgia Power and Southern Nuclear for producing this excellent video update