Oak Ridge brings fusion and fission together for clean energy synergy

Oak Ridge National Laboratory has a long record of advancing fusion and fission science and technology. Today, the lab is focused more than ever on taking advantage of that spectrum of nuclear experience to accelerate a viable path to fusion energy and to speed efficient deployment of advanced nuclear technologies to today’s power plants and future fission systems.

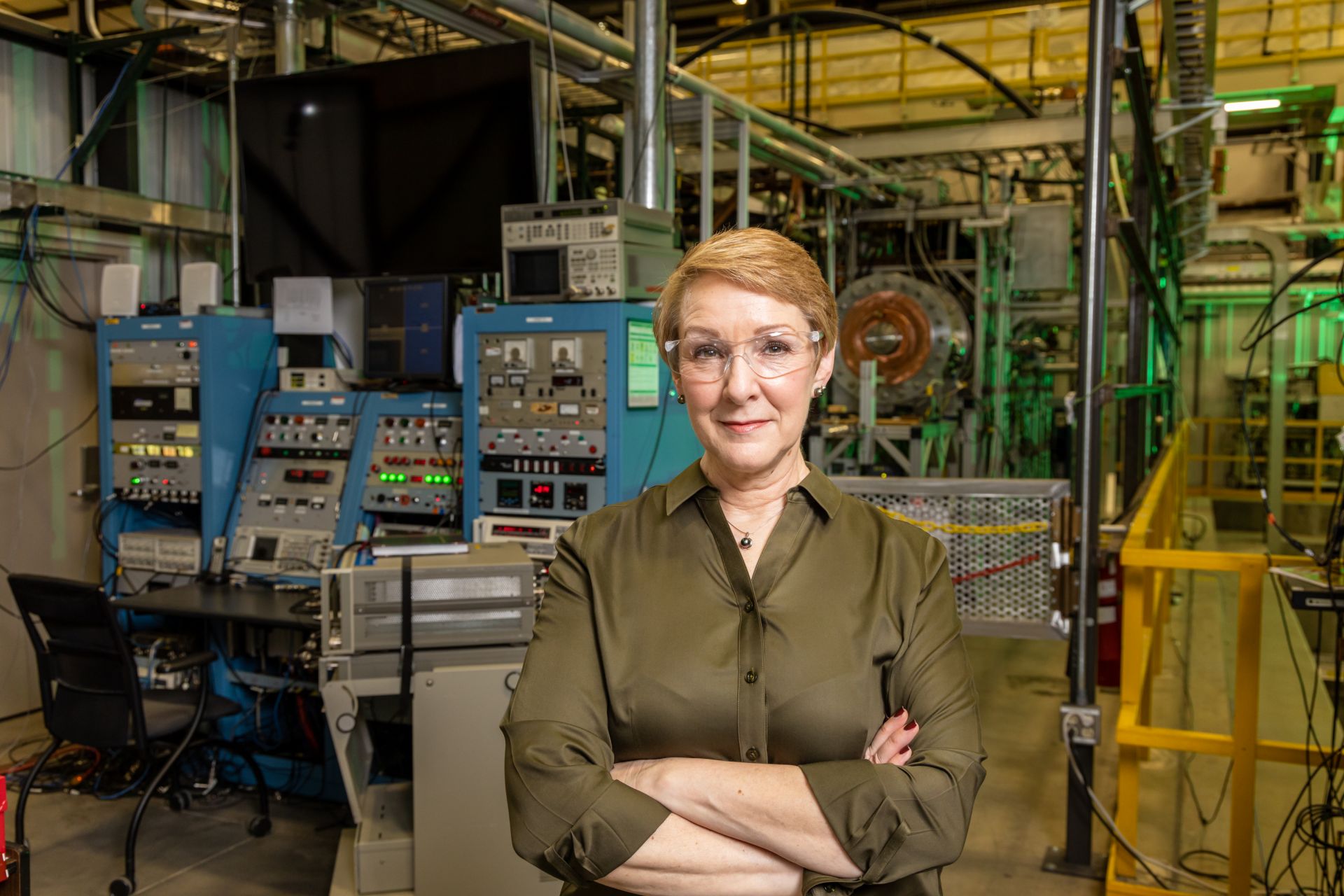

Kathy McCarthy, ORNL associate laboratory director for fusion and fission energy and sciences, said “We want to be the essential partner in the science and technology for both fusion energy and nuclear fission technologies, from concept through industry adoption.”

“We see our role as critical for clean energy, as we are supporting the delivery of carbon-free energy today and designing the future of carbon-free energy.”

ORNL has expertise in the scientific basis of nuclear fusion and fission, nuclear engineering for fusion and fission systems, plus applied experience in integrating and deploying technology.

“The lab understands how to use science to accelerate the technology deployment and how to improve the economics of the current fleet of nuclear reactors while satisfying regulatory requirements,” said Jeremy Busby, division director for nuclear energy and fuel cycle.

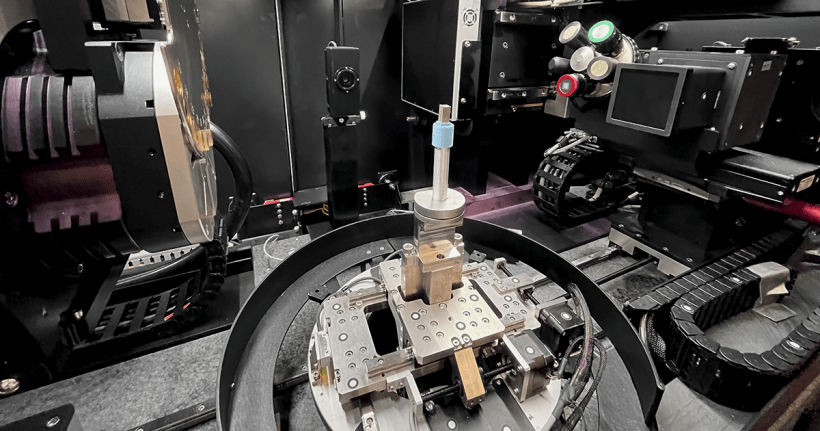

Additively manufactured fuel assembly brackets developed with Framatome are now installed and under operation at TVA Browns Ferry nuclear plant. Photo: ORNL

ORNL also offers a unique combination of resources, thanks to multi-disciplinary facilities and expertise. With opportunities to leverage access to the 85 MW High Flux Isotope Rector (HFIR)—as well as facilities in advanced manufacturing, high-performance computing, neutron scattering, materials sciences, and associated experts across these areas—ORNL has significant advantages for fusion and fission R&D.

One example of how ORNL brings together diverse experts is the transformational challenge reactor program. This effort links innovations in digital design, artificial intelligence, and advanced manufacturing to yield 3D-printed components for reactor applications. The first of these components, fuel assembly brackets developed in collaboration with Framatome, are now installed and under operation at the TVA Browns Ferry nuclear plant. This is the first time additive manufacturing has been used for safety-related parts. ORNL has developed digital twins for these parts—virtual models that replicate processes to collect data to predict how they will perform.

To develop understanding of advanced reactor environments, current fleet performance, and rapidly iterate component designs, ORNL experts leverage nuclear analysis and modelling and simulation capabilities. These capabilities are in demand by current utilities, private fusion and fission industry, and government partners.

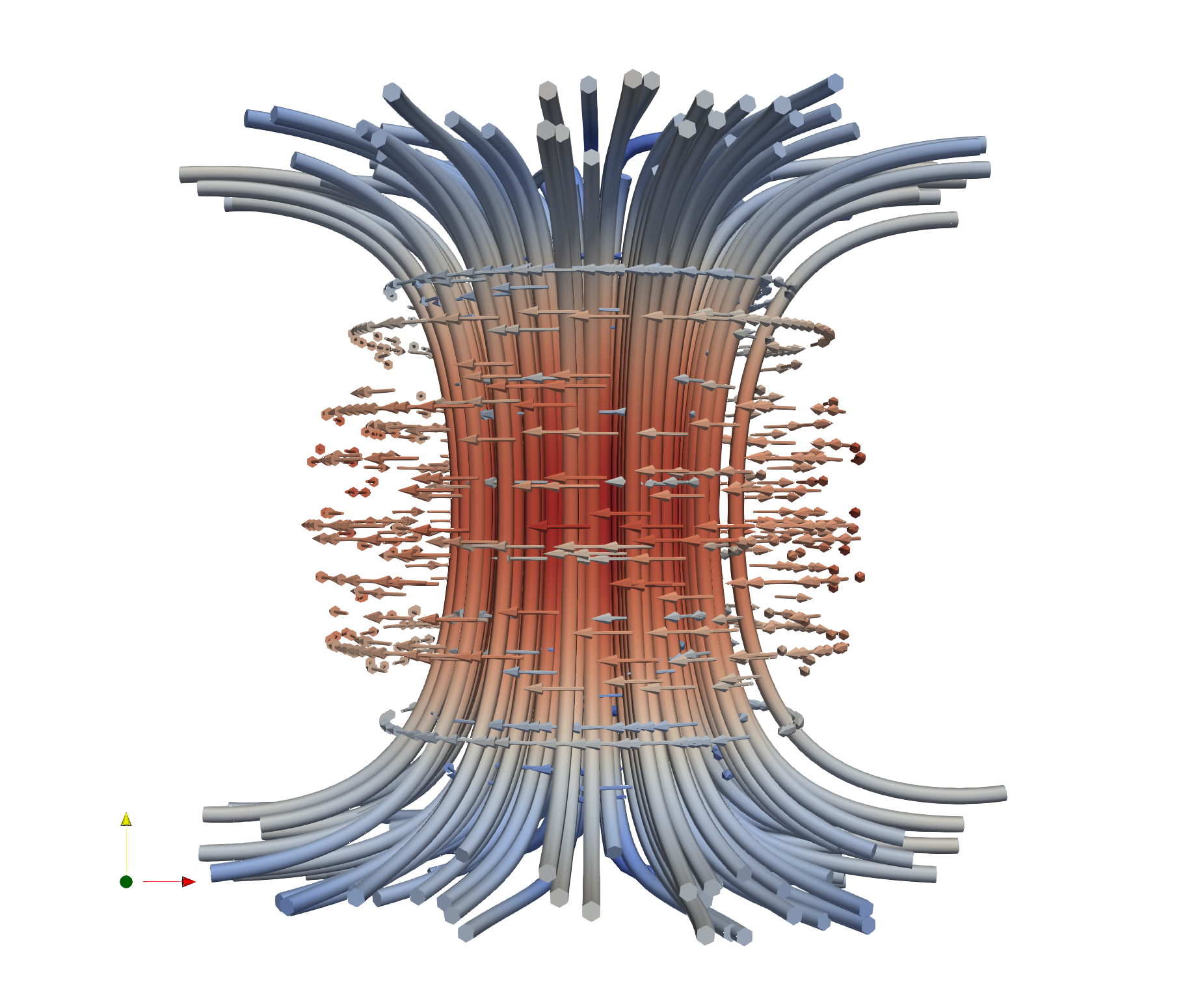

A visualization of magnet fields in fusion plasmas using a mathematical framework developed at ORNL that demonstrated a 100-times reduction in the computational resources required. Photo: D. Green/ORNL

ORNL also has extensive science expertise in nuclear fuels, plus experience in every aspect of the nuclear fuel cycle, from uranium processing to reprocessing and separations to used fuel disposition and packaging.

“Our expertise is well-established in the fundamental science and characterization of fuel cladding and fuel performance, plus in the development of advanced fuel systems,” said Busby.

An accident tolerant fuel experiment development by Global Nuclear Fuel arrives at ORNL for testing. Credit: ORNL

In fusion, ORNL is actively addressing the three main challenge areas that must be resolved to achieve practical fusion systems: self-heating, materials, and handling fusion power.

Oak Ridge manages US ITER, which is responsible for the United States’ hardware contributions to the international ITER fusion project, now under assembly in France. ITER will produce a 500 MW self-heated burning plasma. Sustaining and understanding a burning plasma is considered an essential step for fusion energy development.

An accident tolerant fuel experiment development by Global Nuclear Fuel arrives at ORNL for testing. Photo: ORNL

“The ITER experience with building a power-plant-scale fusion facility yields benefits not only for future fusion devices, but also for advanced fission reactors, as we are working with technologies and fabrication at plant scale,” said McCarthy.

ORNL is also home to the largest fusion materials effort in the Department of Energy Office of Science and is growing its fusion technology scope to develop the foundation for fusion fuel-breeding via blanket technology development.

“It’s an exciting time at Oak Ridge. We can benefit from unique synergies by bringing fusion and fission expertise closer together. And I think that is a very good thing for clean energy in both the short and long term,” said McCarthy.