Innovation in Fuel Reliability and Spent Fuel Cask Loading

Dominion Engineering, Inc. (DEI) has developed a number of innovative and cost effective tools and services designed to improve fuel reliability and spent fuel cask loading operations. This includes BNDETM fuel cleaning, which effectively removes debris from all reload fuel bundles without significantly impacting outage schedule. Smart-SipTM fuel sipping, a related activity, provides much higher fidelity leak detection capability than traditional vacuum canister sipping equipment, ensuring tight leaks are reliably identified and dispositioned during refueling outages and prior to spent fuel cask loading operations. Related industry experience is discussed further below.

BNDE Fuel Cleaning

When foreign material enters the reactor system, either during maintenance activities or as components degrade, this material can be transported to the fuel bundles and cause a fuel failure. Debris failures have generally been observed more frequently at BWRs, but also pose a risk for PWR and VVER units. Before debris-induced fuel failures occur, foreign material typically becomes trapped on the lower debris screen in the fuel bundle bottom nozzle for some period of time, providing an opportunity to remove the debris before it causes any fuel damage.

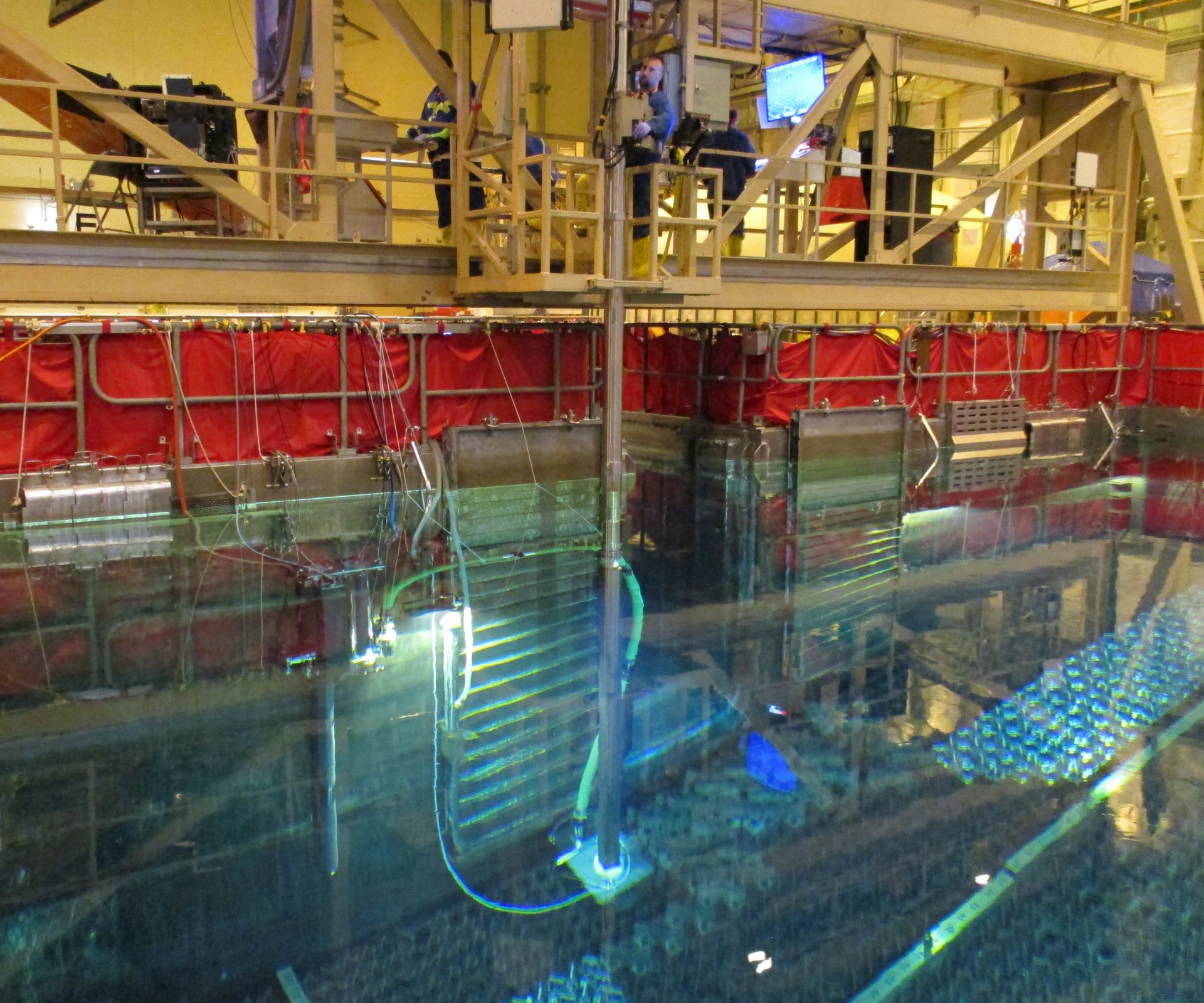

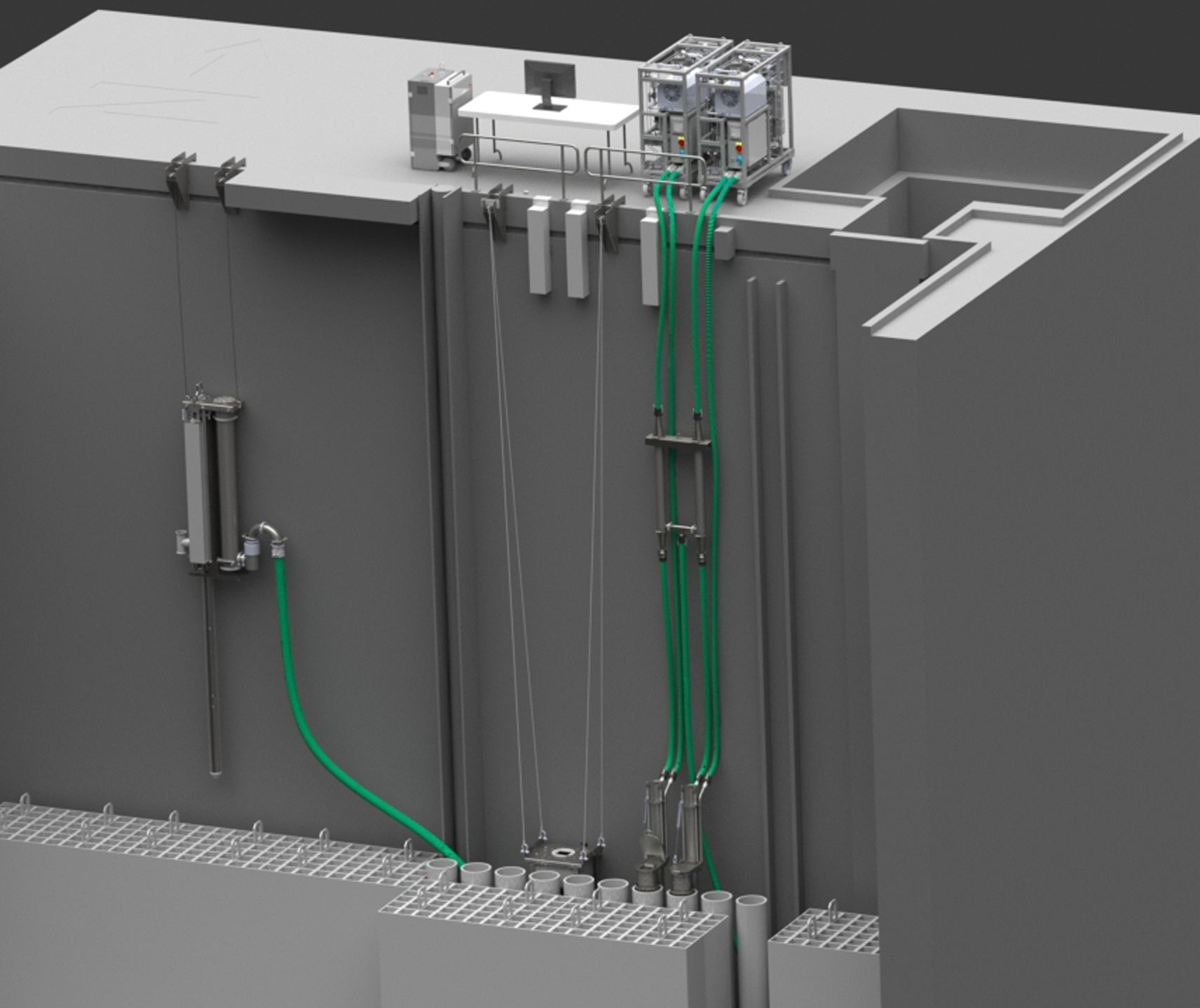

Figure 1

DEI’s patented bottom nozzle debris elimination (BNDE) equipment uses a combination of ultrasonic energy and vacuuming to remove and positively capture any debris present. The cleaning process takes about 2 minutes per fuel bundle and has proven to be a practical and effective way to remove potentially damaging debris from all reload bundles without a significant impact on the outage schedule or on other refueling activities. The BNDE system also includes an integrated visual inspection system, which facilitates cleaning and inspection in parallel and may further reduce cleaning time. BNDE offers a significant advancement relative to prior generation FOSAR and manual debris removal techniques, which generally take too long to be efficiently integrated with normal refueling activities. BNDE equipment and operations are shown in Figure 1.

The BNDE equipment is an adaptation of DEI’s full length high efficiency ultrasonic fuel cleaning (HE-UFC) system, which has been safely used in hundreds of applications at PWR units to improve fuel performance and radiological conditions, in addition to achieving debris and foreign material removal. To date, more than 20 BNDE and HE-UFC fuel cleaning campaigns have been successfully completed at BWRs. Three of the BWR units that have performed BNDE or HE-UFC were experiencing active debris-induced fuel failures prior to these operations and in all cases, the debris-induced fuel failures were arrested as a result of the cleaning activity.

Based on industry experience showing consistent success in arresting active debris-induced fuel failures, units with persistent or intermittent debris issues now consider BNDE as a primary corrective measure. Additionally, many plants have applied BNDE as a preventive measure following known or suspected foreign material ingress, or following maintenance activities where there is a possibility that such ingress could occur. In general, BNDE is often performed as part of plant responses to INPO Event Report (IER) L2-19-6, “Preventing Debris-Induced Fuel Failures.”

Data from the plant operations highlighted above has revealed that the prevalence of debris on fuel bundles is generally higher than previously appreciated. Specifically, when BNDE has been performed, debris and foreign material has typically been observed on the bottom nozzle of 25-50% of the reload fuel bundles prior to cleaning. Industry experience has shown that the BNDE cleaning process is effective in removing debris from approximately 90% of the fuel bundles identified to have debris present, significantly reducing the risk of a fuel failure during subsequent operation. Once collected, some sites perform analysis of the debris and foreign material collected in order to identify the composition and possibly the source of the material, and to plan any further mitigative measures.

“For more than 20 years, DEI has performed full length ultrasonic fuel cleaning at PWR sites to effectively manage crud-induced power shift (CIPS) / axial offset anomaly (AOA) and to support zinc injection programs for dose rate reduction,” said DEI President Mike Little. “We are excited to now be using our BNDE technology to assist BWR and PWR sites in enhancing fuel reliability by reducing the risk of debris-induced fuel failures.”

Smart-Sip Fuel Sipping

Because BNDE fuel cleaning activities are sometimes performed in response to a debris induced fuel failure, these activities may be performed concurrently with fuel sipping to identify and isolate leaking fuel bundles. As discussed further below, DEI’s Smart-Sip fuel sipping systems offer a number of design and functional enhancements compared to older vintage vacuum canister sipping equipment and provide a cost effective option for high fidelity fuel sipping both during refueling outages and in preparation for spent fuel cask loading operations.

Very often when a fuel leak is detected, sipping is performed using vacuum canister sipping systems, which are generally regarded as the most sensitive type of fuel sipping equipment currently available. However, older generation vacuum canister fuel sipping systems are sometimes not effective in positively identifying fuel leaks, either because the leaks are very tight (low signal) and/or because the background signal is high due to prior fuel leaks or sipping activities. This can result in lost time during refueling outages and/or complications in planning and execution of fuel reloading prior to restart.

As discussed in NRC Information Notice 2018-01 (ML17234A705), undetected leaks have also been discovered during spent fuel cask loading operations, leading to unexpected noble fission gas releases and additional technical challenges to justify that the loaded fuel has remained undamaged. Reliable leak detection in support of spent fuel cask loading may be further challenged due to the fact that leak signals from fuel bundles have decayed over many years of storage in spent fuel pools, resulting in even lower leak signals.

Having delivered vacuum canister sipping systems and services for more than 15 years, DEI developed its latest vintage Smart-Sip technology to address the issues above and also to incorporate design and functional enhancements that address other operational lessons learned. Smart-Sip is a vacuum canister-type sipping system that incorporates the latest available detection technology and a proprietary fission gas

removal system to constantly strip out background activity during the sipping process. This system is

capable of positively detecting and dispositioning tight leak signals with much greater precision and

fidelity than was previously possible with older vintage vacuum canister sipping systems.

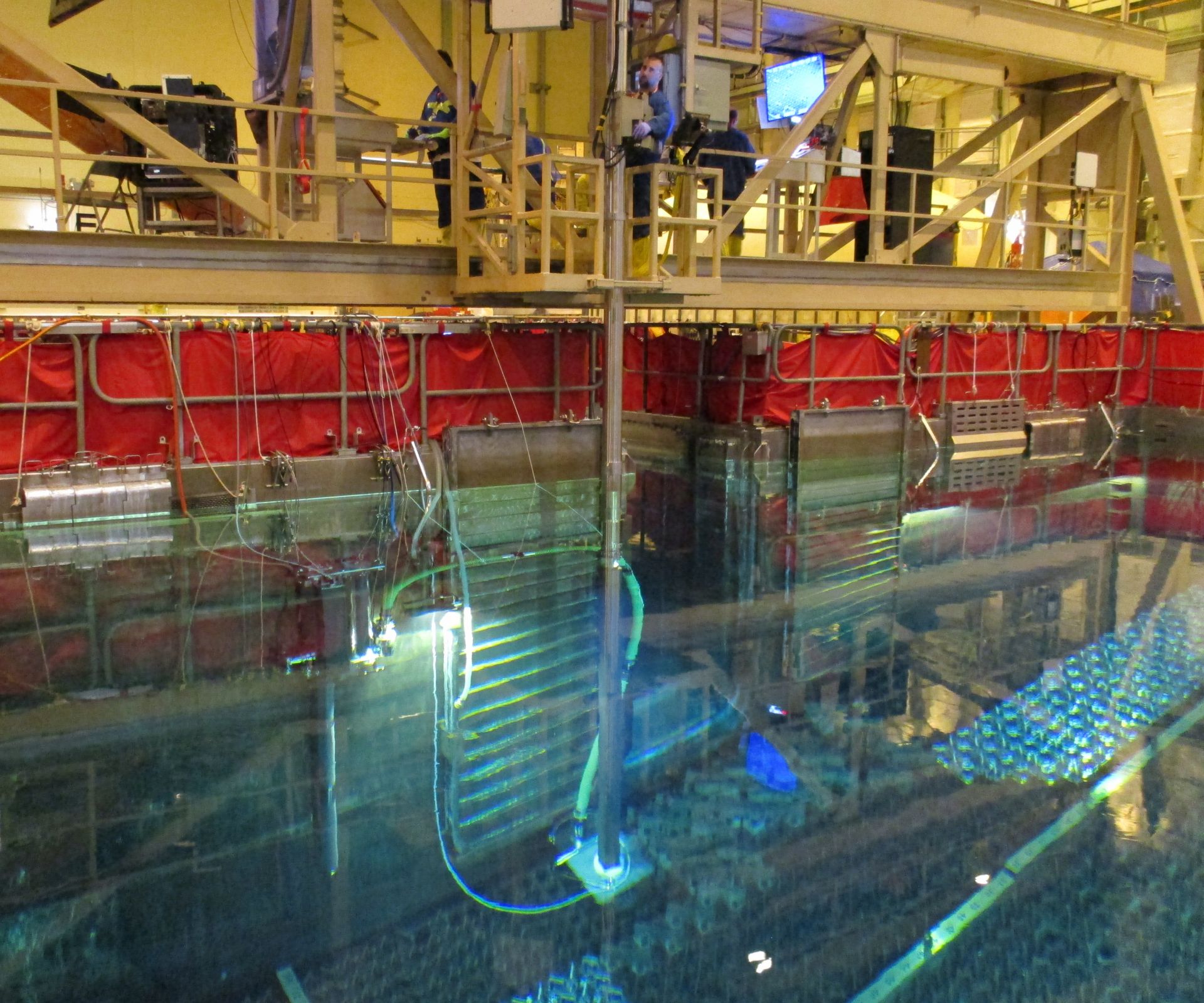

Figure 2

A typical Smart-Sip installation, integrated with BNDE cleaning at a BWR, is shown in Figure 2. The canisters are very compact and can be installed in multipurpose cells or in the upper containment pool in a BWR-6, which provides significant schedule savings when performing sipping during a refueling outage. Larger canisters are also available for sipping PWR fuel and leverage the same proprietary Smart-Sip control system for high fidelity leak detection.

Smart-Sip is ideal for situations where high fidelity fuel leak detection is required, but also offers a cost effective option for more routine fuel leak detection applications. DEI offers a variety of Smart-Sip delivery models including turn-key fuel sipping services and fuel sipping equipment sale and rental, with technical support for equipment maintenance, operation and training. Smart-Sip is suitable for use during both refueling outages and in preparation for spent fuel cask loading operations at both PWRs and BWRs, and may be performed in combination with BNDE or HE-UFC fuel cleaning or as a separate activity.

For more information regarding Smart-Sip fuel sipping, BNDE fuel cleaning or HE-UFC fuel cleaning, please contact info@domeng.com