Preventative Maintenance for Improved Fuel Reliability & Performance

The process of making fuel for our light-water nuclear plants is meticulously developed and executed. And as anyone who has gone through the receipt process once it arrives at the plant can attest, the initial quality examination is likewise a thorough and rigorous activity. We do a great job of making sure that high quality fuel is ready to go into the core.

But what can we do to improve fuel reliability and avoid fuel failures once a fuel assembly has already operated for one or more cycles? Dose rates, strict refuel schedules, and sheer distance below the pool surface make it very difficult to determine if there are problems or even precursors present before fuel is loaded back into the reactor core. Preventative Maintenance (PMs) permeate our lives at power plants, but for one of the most critical components in our facility, we can be challenged to apply that strategy to our fuel. The good news is that it can be done with very effective outcomes because the three simple concepts around preventative maintenance can just as easily be applied to fuel assemblies: initiate activities to identify any problems, resolve the immediate issue(s), and then mitigate future degradation that would result in significant failure of that component or function, in this case, our fuel integrity.

Visual inspection of fuel is our best chance to catch fuel integrity precursors. Foreign material is a common cause of fuel failures, particularly at BWRs. While many of us have focused on FME prevention from reactor service activities—mainly because we have beat that drum consistently over the last 30 years— that alone may not be the culprit. More and more we are seeing that long term component degradation and failure to retrieve objects from many years past play an important role in contributing to fuel leaks. As our plants age, common modes of failure such as deteriorating valve seats introduce material that can be transported throughout our reactor system and ultimately end up affecting fuel reliability.

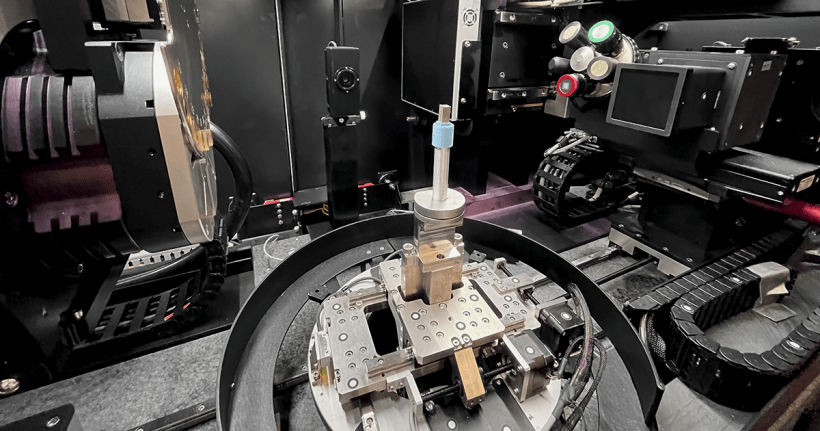

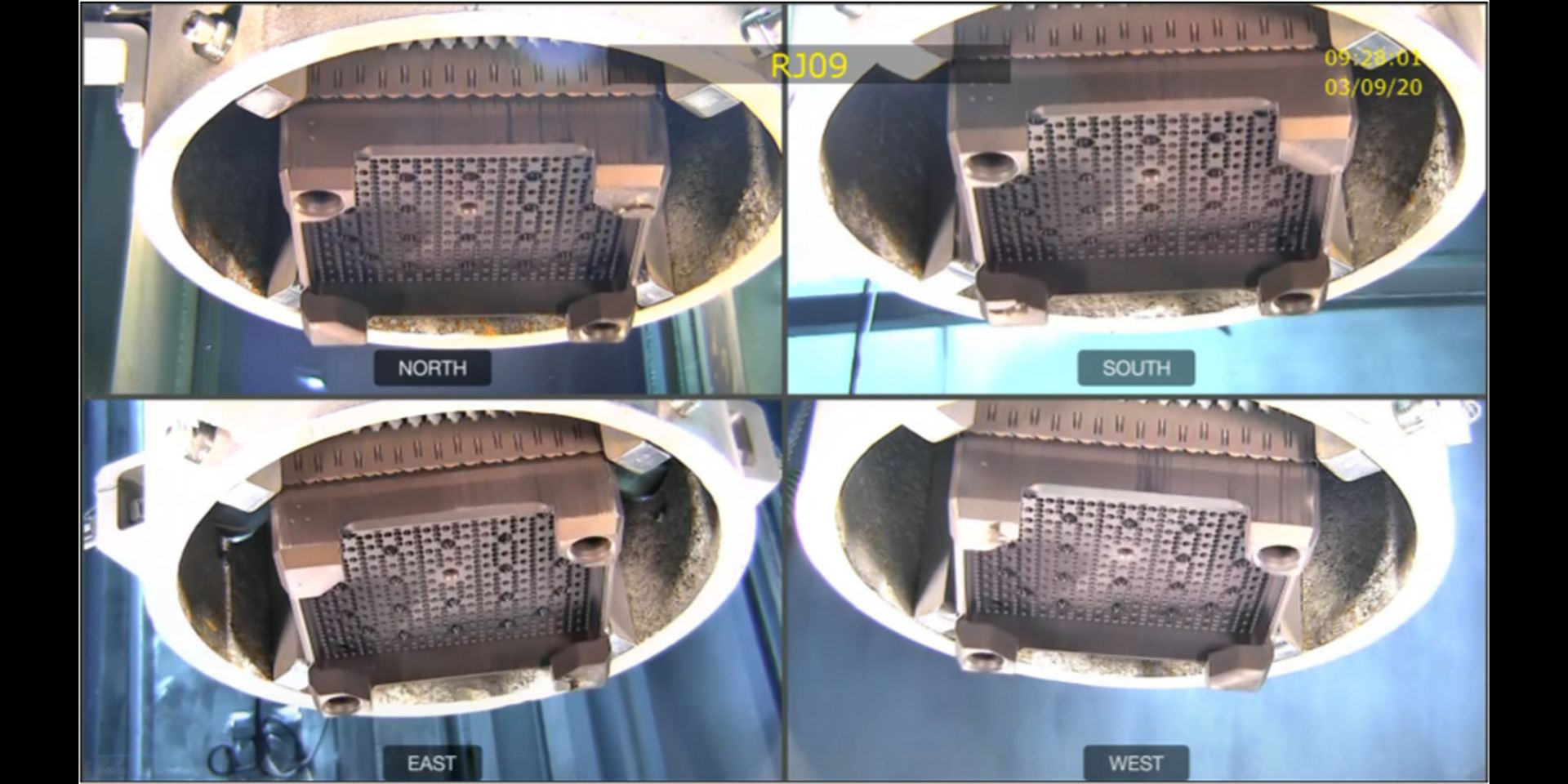

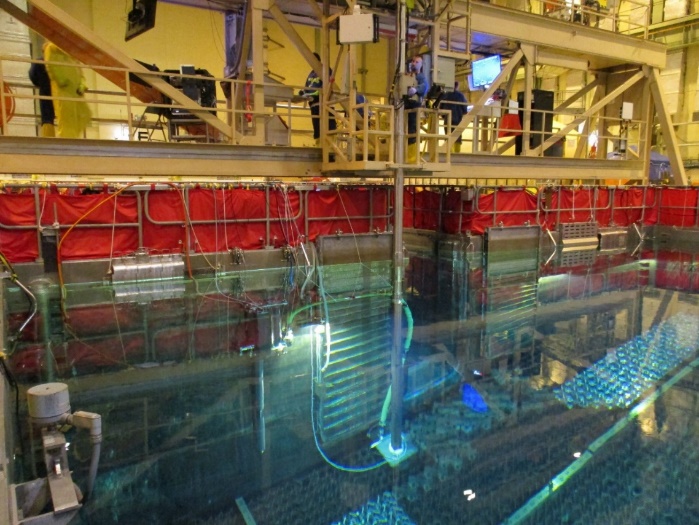

Being able to spot debris that has made it that far is an advantage, but it requires precision optics capable of handling high radiation that also do not significantly impact fuel-movement times. Getting a clear picture of what is on the bottom of a fuel assembly during transit can help make the determination if a potential problem is already present on your fuel. Dominion Engineering’s (DEI’s) high-definition visual inspection systems are engineered to consistently provide excellent lighting and video quality, even in high radiation fields. These systems utilize intuitive control units, cost-effective consumables and a compact, modular shielding design that allows these systems to be installed in a variety of locations to optimize fuel movement logistics and minimize impact on outage schedule. For example, these systems are easily integrated with the upender, fuel rack and/or with fuel cleaning equipment.

HD 4-face and Bottom Nozzle Inspection System

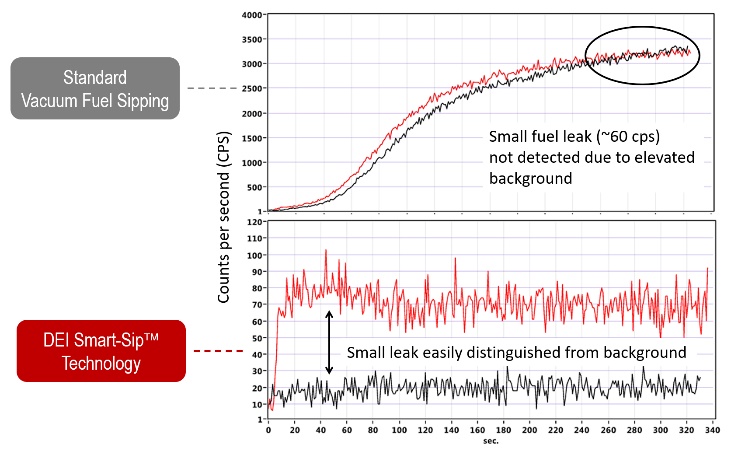

With fuel failures, the most obvious method of identification is the release of radioactive fission gases. However, these leaks are often very small and depending on background radiation levels in fuel pools, it may be difficult to identify and isolate a leaking fuel assembly. Fuel sipping, especially with the newest generation capabilities to reduce background activity, can be useful in identifying fuel concerns and preventing assemblies with small leaks from being reloaded to the core. For instance, DEI’s Smart-Sip system is a high-definition vacuum canister sipping system that removes background fission gases before sampling, resulting in much higher detection capability for problematically low activity leaks.

With fuel failures, the most obvious method of identification is the release of radioactive fission gases. However, these leaks are often very small and depending on background radiation levels in fuel pools, it may be difficult to identify and isolate a leaking fuel assembly. Fuel sipping, especially with the newest generation capabilities to reduce background activity, can be useful in identifying fuel concerns and preventing assemblies with small leaks from being reloaded to the core. For instance, DEI’s Smart-Sip system is a high-definition vacuum canister sipping system that removes background fission gases before sampling, resulting in much higher detection capability for problematically low activity leaks.

Enhanced Leak Detection Results with Smart-Sip HD Fuel Sipping

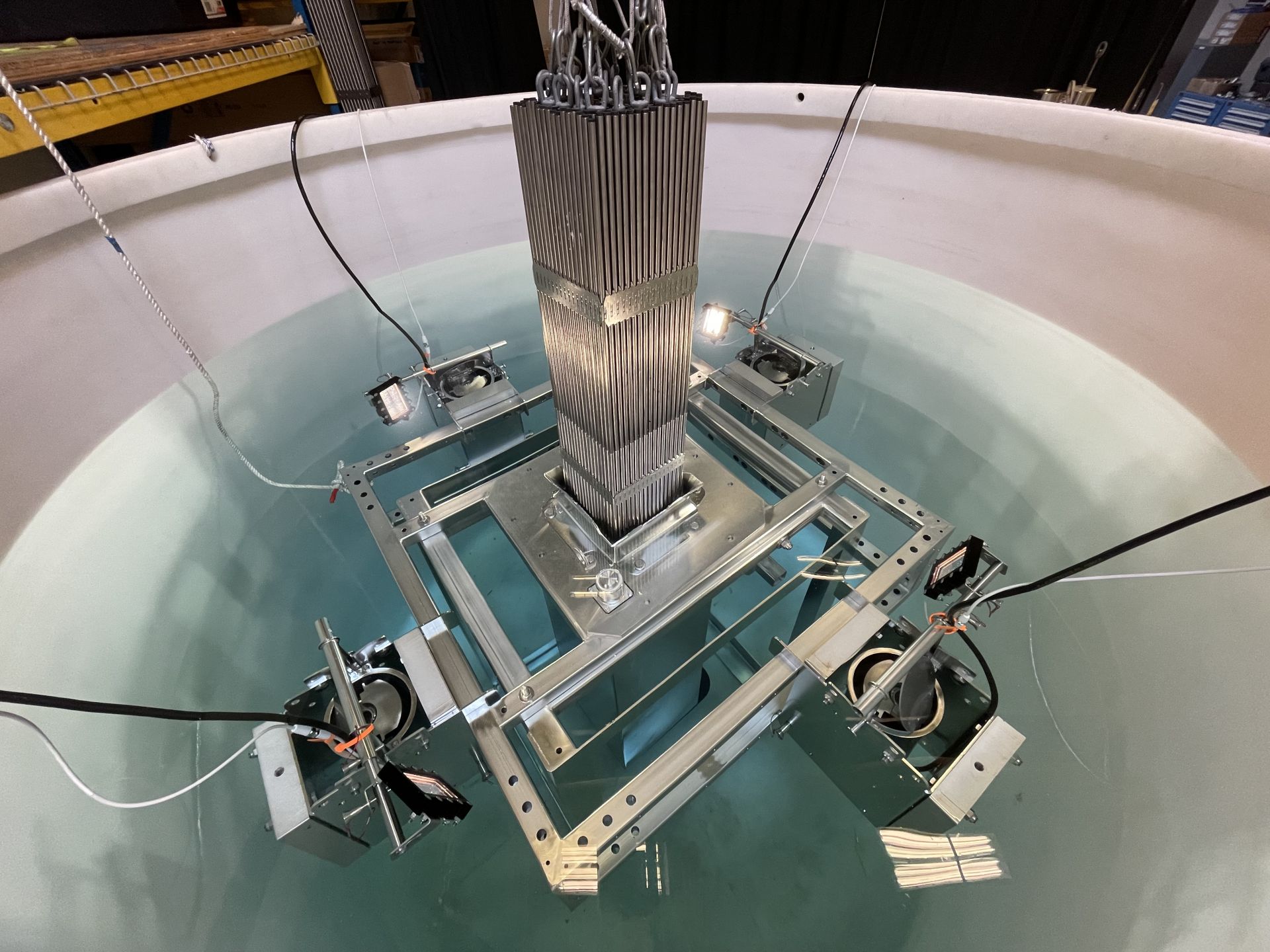

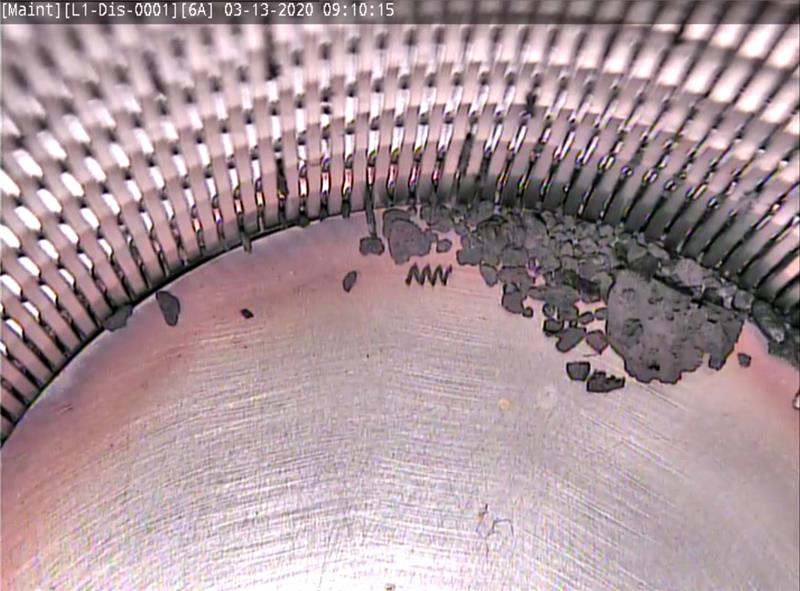

Once a leaking fuel assembly is identified, it can be moved to the fuel pool to prevent any further impacts. Managing debris and foreign material, sometimes trapped on the underside of lower tie plates in fuel assembly bottom nozzles as it migrates through the reactor system, offers more of a challenge. One method that has proven successful at several nuclear plants is using ultrasonic fuel cleaning systems. DEI has developed several equipment systems which utilize a combination of ultrasonic energy and reverse flow to disrupt and capture foreign material. Our Bottom Nozzle Debris Elimination (BNDE) system is used for cleaning and inspecting the bottom nozzle of fuel assemblies, while our High Efficiency Ultrasonic Fuel Cleaning (HE-UFC) system is used to remove crud and debris from the full length of the fuel bundle, including the bottom nozzle assembly. These cleaning systems are designed for quick and efficient removal of foreign material from fuel assemblies, and simultaneous inspection to confirm foreign material removal – making it practical to efficiently complete this process on large numbers of reload fuel bundles during refueling outages.

Once a leaking fuel assembly is identified, it can be moved to the fuel pool to prevent any further impacts. Managing debris and foreign material, sometimes trapped on the underside of lower tie plates in fuel assembly bottom nozzles as it migrates through the reactor system, offers more of a challenge. One method that has proven successful at several nuclear plants is using ultrasonic fuel cleaning systems. DEI has developed several equipment systems which utilize a combination of ultrasonic energy and reverse flow to disrupt and capture foreign material. Our Bottom Nozzle Debris Elimination (BNDE) system is used for cleaning and inspecting the bottom nozzle of fuel assemblies, while our High Efficiency Ultrasonic Fuel Cleaning (HE-UFC) system is used to remove crud and debris from the full length of the fuel bundle, including the bottom nozzle assembly. These cleaning systems are designed for quick and efficient removal of foreign material from fuel assemblies, and simultaneous inspection to confirm foreign material removal – making it practical to efficiently complete this process on large numbers of reload fuel bundles during refueling outages.

BNDE Fuel Cleaning Operation to Remove Foreign Material / Debris

Once the material is removed, it becomes very important for us to understand where it came from and identify what we can do to mitigate future introduction of this unwanted source of foreign material. As discussed in INPO’s IER L2-19-6, Recommendation 2.c, characterization of the debris is necessary to identify the source. Technology has come a long way in the past two decades, and plants now have many cost-efficient options to properly and accurately determine the material’s origin. These include visual inspection, offsite laboratory evaluation, and onsite compositional analysis of the material. If you can determine the composition or source either visually or analytically, differentiating characteristics of components (composition, age/vintage, etc.) may be used to determine which ones may be introducing the material. Such post-cleaning analysis is routinely performed on debris and foreign material removed during BNDE and HE-UFC cleanings in order to focus other complementary maintenance activities and further enhance fuel reliability and performance.

Once the material is removed, it becomes very important for us to understand where it came from and identify what we can do to mitigate future introduction of this unwanted source of foreign material. As discussed in INPO’s IER L2-19-6, Recommendation 2.c, characterization of the debris is necessary to identify the source. Technology has come a long way in the past two decades, and plants now have many cost-efficient options to properly and accurately determine the material’s origin. These include visual inspection, offsite laboratory evaluation, and onsite compositional analysis of the material. If you can determine the composition or source either visually or analytically, differentiating characteristics of components (composition, age/vintage, etc.) may be used to determine which ones may be introducing the material. Such post-cleaning analysis is routinely performed on debris and foreign material removed during BNDE and HE-UFC cleanings in order to focus other complementary maintenance activities and further enhance fuel reliability and performance.

|  |

Example Debris Removed during BNDE and HE-UFC Fuel Cleaning

DEI is committed to helping the nuclear industry arrest fuel failures and eliminate debris-induced challenges going forward. In addition to our ultrasonic fuel cleaning activities, we offer several complementary services, including high-definition visual inspection and sipping, and characterization of debris collected during fuel cleaning activities. DEI’s integrated fuel inspection, sipping and cleaning services have been effective in assisting both PWR and BWR sites maintain and improve fuel reliability and performance. Reach out to us today to discuss how we can help with keeping your fuel healthy for the long run.

For more information, contact Dale Vines (dvines@domeng.com) or Mike Little (mlittle@domeng.com), if you have questions or would like to discuss options for reducing debris-induced fuel failures.