Value Study: Fire Protection Optimization

Fire System Inspection and Maintenance

In nuclear power production fire prevention is an everyday practice 24/7. The active and passive fire protection systems account for nearly 40% of all core damage frequency. With this significant risk, nuclear plants that are extending their operating license are faced with updating antiquated fire prevention systems and components. Westinghouse can help as illustrated in the case study below.

Westinghouse experts performed an evaluation of a North American utility’s Fire Protection Program, with industry best practices and planned site changes in mind, to develop a risk-based model that addressed the current and future fire risk profile up to 2030.

The developed model allowed the utility to assess the degree in which independent buildings, as well as the site as a whole, met the fire protection goals of the governing code and standards. The risk-based model allowed analysis of inspection, testing, and maintenance intervals to determine if it would be appropriate to increase the interval based on device performance. It also addressed the need for fire brigade personnel as the site developed into its final state in 2030, based on the risk at a given point in time.

The added flexibility of the risk-based fire protection program allowed cost savings while maintaining regulatory requirements.

The program also enabled performance of site activities with an acceptable low risk of fire, as well as managing the total cost of delivery of the Fire Protection Program.

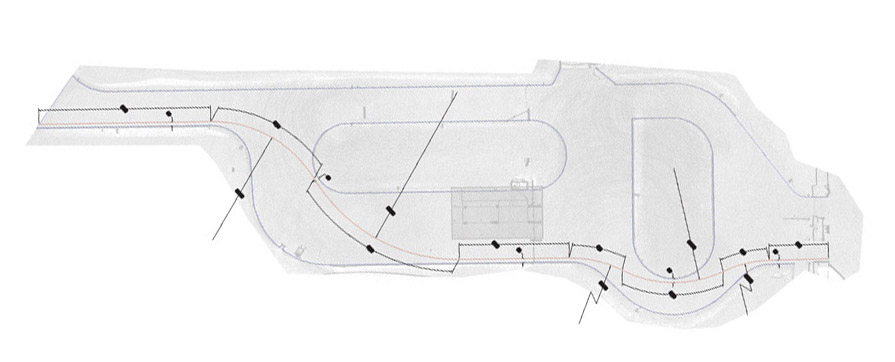

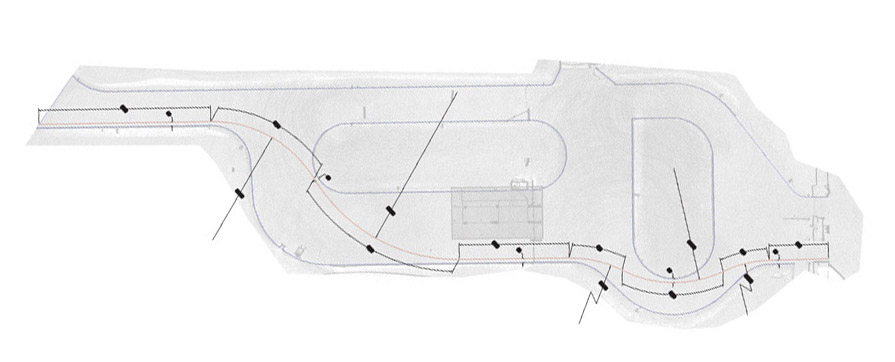

Point Cloud model of vehicle access point with adversary vehicle path overlaid

Camera Tree

Secondary Alarm Station Layout

Value Study: 3D Scanning and Modeling for Vehicle Speed and Blast Effects

Westinghouse was contracted by a U.S. nuclear site to perform Vehicle Speed and Blast Effect Calculations based on concerns from the NRC. The site did not have a to-scale plot plan for the entry area and sally-port. The vehicle speed analysis requires accurate site layouts, radii of vehicle paths, and distances to determine the maximum vehicle speed at impact with the Vehicle Barrier System.

Westinghouse used an advanced 3D point-cloud scanning tool to develop a 3D model of the location, accurate to the nearest inch. The project team then developed 3D pathways at varying standoffs from curbs to develop the maximum velocity the adversary vehicles could attain.

Using the 3D scanning and modeling, Westinghouse was able to minimize the layout development cost, with greater accuracy, and use the model to build accurate radii and distance measurements. The site was able to clearly show the regulator that vehicle velocities were accurate to an exceptional degree. Both the utility and regulator were pleased with use of technology, the accuracy, and the efficiency of the project.

Value Study: Security Computer System Upgrades and Integration

Westinghouse Physical Security experts provided Design Control Documents (DCD), Combined License Application (COLA), and site-specific analyses, specifications, design, procurement, testing, installation, and construction support deliverables for the entirety of new plant construction. In doing so, Westinghouse developed critical experience in modern security computer systems, regulatory outlook, key project requirements, and construction best-practices.

Westinghouse security engineers are experts in engineering, procurement, and construction contracts for security computer system upgrades. Our team is comprised of professional engineers with detailed knowledge, experience and training in security solutions. We find and fix underlying design and project issues before they become consequences.

To discuss a custom Fire Protection solution for you, contact Thomas.Swanson@westinghouse.com.

If you’re taking on a security upgrade, contact Amanda.Jordan@westinghouse.com.