iLAMP: Neutron Absorber Material Monitoring for Spent Fuel Pools

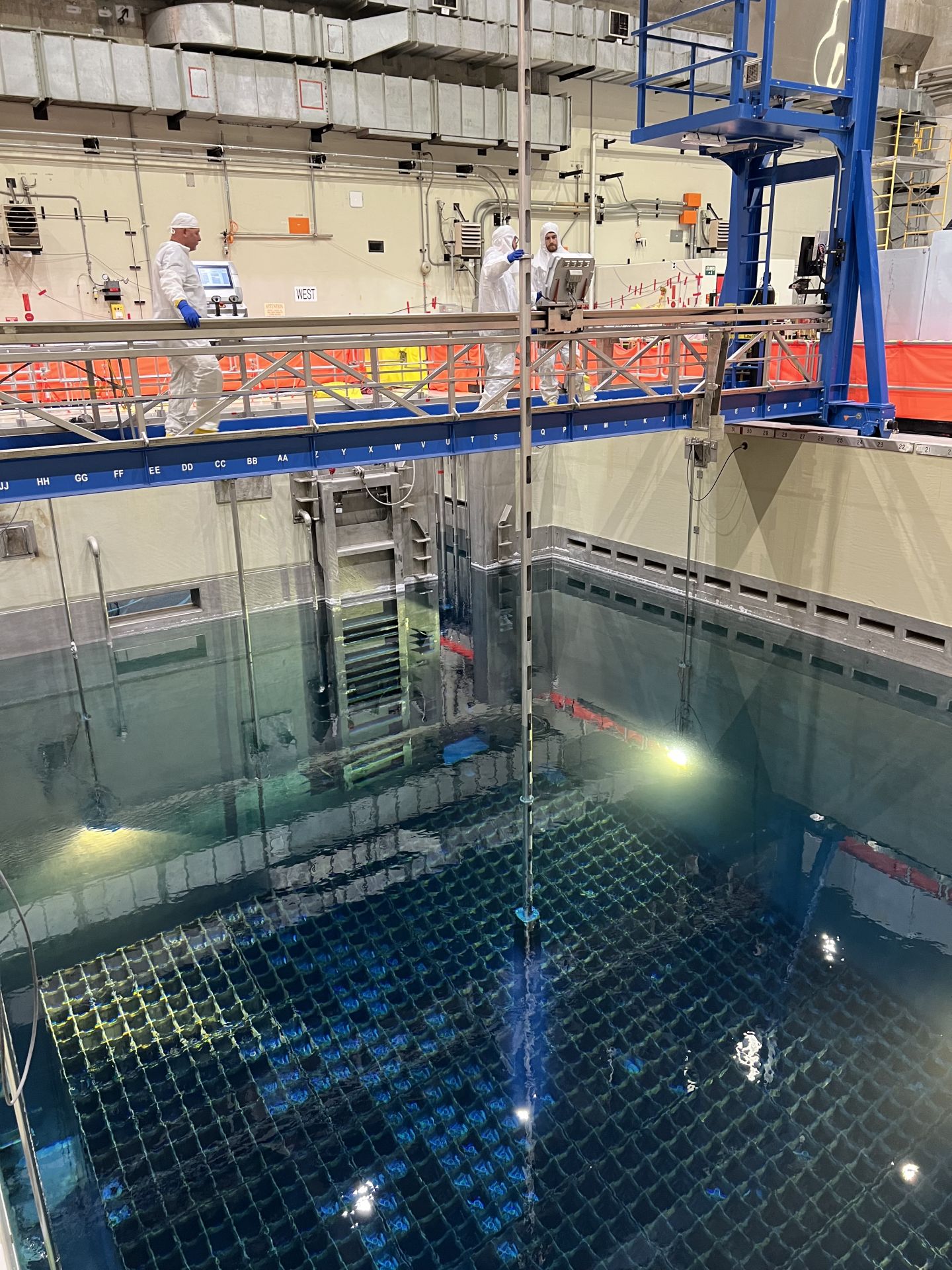

The spent fuel pool at TVA’s Watts Bar nuclear power plant near Spring City, Tenn. (Photo: TVA)

Neutron absorber materials are used by nuclear power plants to maintain criticality safety margins in their spent nuclear fuel pools. These materials are typically in the form of fixed panels of a neutron-absorbing composite material that is placed within the fuel pools. (A comprehensive review of such materials used in wet storage pools and dry storage has been provided by the Electric Power Research Institute (EPRI) [1]).

With increasing plant life, there is a need to maintain or establish a monitoring program for neutron absorber materials—if one is not already in place—as part of aging management plans for reactor spent fuel pools.

Such monitoring programs are necessary to verify that the neutron absorbers continue to provide the criticality safety margins relied upon in the criticality analyses of a reactor’s spent fuel pool. To do this, the monitoring program must be capable of identifying any changes to the material and quantifying those changes. It should be noted that not all the changes (for example minor pitting and blistering of the absorber material) will result in statistically or operationally significant impact on the criticality safety margins.

For monitoring neutron absorber materials in spent fuel pools, until recently, two alternatives existed—coupon testing and in situ measurements. A third option, called industry-wide learning aging management program (i-LAMP), was proposed by EPRI and is currently in the final stages of the regulatory review. The following sections describe these monitoring approaches.