GAIN awards include plan to integrate fast reactor test vehicle in Oklo’s Aurora

The Department of Energy and the Gateway for Accelerated Innovation in Nuclear (GAIN) on March 19 announced the second round of fiscal year 2024 voucher awards to three companies: Element Factory, Kanata America, and Oklo.

Filling a gap for sodium fast reactor testing: The voucher awarded to Oklo Inc. of Santa Clara, Calif., will see Idaho National Laboratory get funding to support the preconceptual design of a test vehicle for sodium fast reactor fuels testing in Oklo’s commercial demonstration reactor, which is planned for deployment at INL.

As the abstract for Oklo’s GAIN award emphasizes, “Currently, a suitable test reactor does not exist within the U.S. for performing prototypic sodium fast reactor fuels and materials testing. While tests using the Advanced Test Reactor (ATR) have been beneficial, there are shortcomings: the need for high-enriched uranium (HEU) to achieve prototypic burnups, the inability to test pilot-scale fuels and fabrications processes, and the inability to match the prototypic operating conditions of sodium fast reactors.”

For that reason, “Oklo intends to use its initial Aurora powerhouse at INL to support irradiation and testing of advanced fuel forms.” Working together, Oklo and INL will “determine the layout of a test facility and support completion of the preconceptual design of the experimental test vehicle that will be used to expand existing fuels data.”

Testing potential: Other sodium fast reactor developers, including TerraPower, also require data on fuels and materials for sodium fast reactors that are not easily obtained, given the lack of versatile testing capabilities in the fast neutron spectrum. Asked about the potential for the planned testing vehicle to benefit other sodium fast reactor development, Bonita Chester, Oklo’s director of communications and media, told Nuclear News that the GAIN award's focus is on test capabilities to support the commercialization of advanced fuels and materials for Oklo.

“Our plant at INL is a commercial, NRC-licensed power plant, not a test reactor. Our primary focus remains on commercial power generation,” Chester emphasized. Oklo’s Aurora could produce up to 15 megawatts of power. “However,” she continued, “our design incorporates flexibility that allows for testing new fuels and materials, many of which are common across sodium fast reactor developers. We are excited to leverage INL's expertise in the development of these test capabilities.”

Other Oklo developments: In January, Oklo announced that the DOE had approved the safety design strategy for the company’s Aurora fuel fabrication facility, which will also be sited at INL. That facility is being designed to demonstrate the reuse of recovered nuclear material to fuel Oklo’s demonstration reactor.

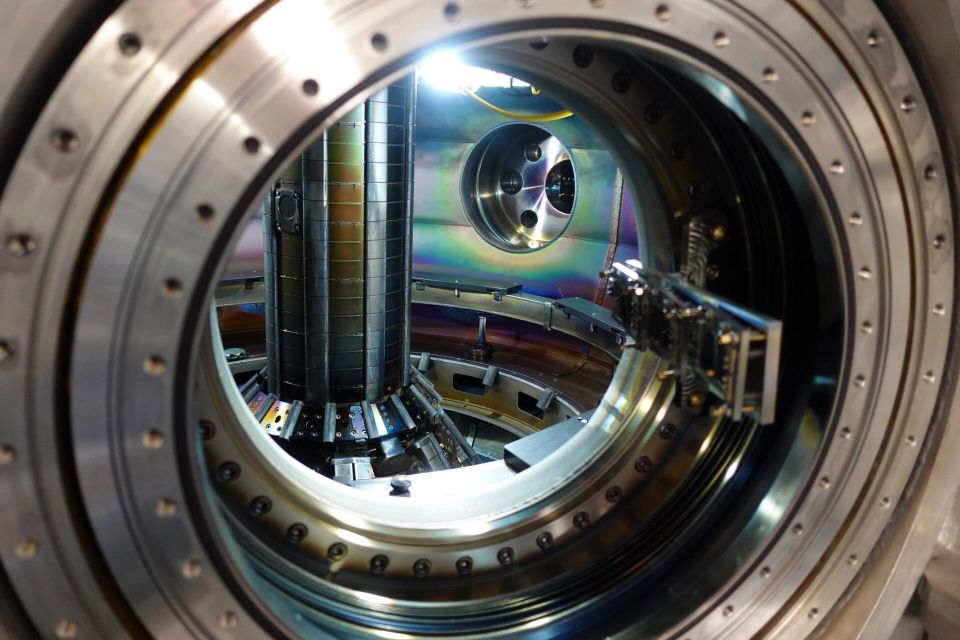

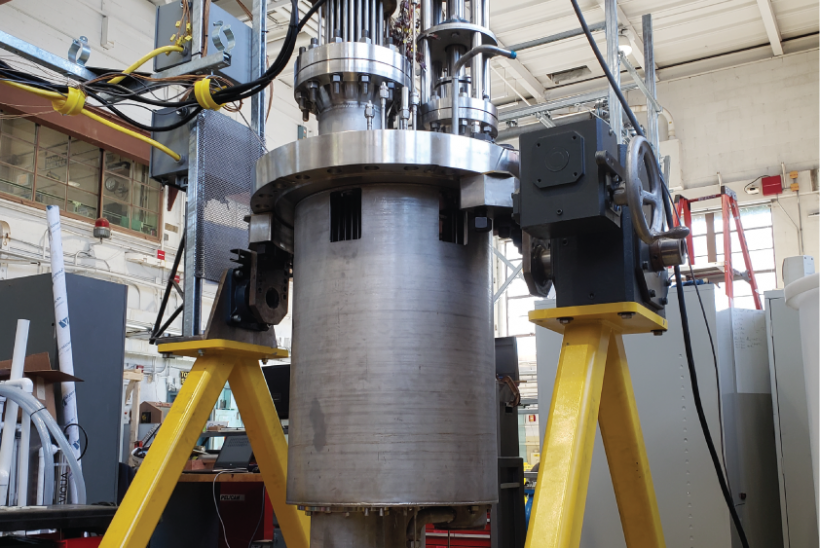

Earlier this month, Oklo announced that it had reached a milestone in its thermal-hydraulic testing campaign being carried out at Argonne National Laboratory under a separate GAIN voucher announced in 2021. Using the Thermal Hydraulic Experimental Test Article (THETA), a sodium test loop at Argonne’s Mechanisms Engineering Test Loop Facility (METL), Oklo and Argonne have completed the second phase of the testing campaign to study key thermal-hydraulic behavior and provide high-fidelity data for design optimization.

Other Round 2 GAIN awards: GAIN vouchers, which include a minimum 20 percent cost share provide advanced nuclear technology innovators with access to the extensive nuclear research capabilities and expertise available across the national laboratory complex to help businesses overcome critical technological and commercialization challenges. There were two other round-two FY2024 awards:

Element Factory LLC, of Cheyenne, Wyo., received an award to investigate spark plasma sintering process development with INL for graphite neutron moderator production, with the goal of developing a cheaper, easier source of graphite for the nuclear energy industry. INL will assist in developing specifications for carbon/graphite powder and compile quality assurance/quality control approaches and documentation requirements for producing nuclear-grade graphite components from the carbon powder precursor using spark plasma sintering.

Kanata America Inc., also of Cheyenne, Wyo., will use its award to study thermal energy storage with supercritical carbon dioxide power conversion for microreactors. Kanata, which will work with Sandia National Laboratories, is an indigenous-led “developer, builder, owner, and operator of decarbonization intellectual property and infrastructure assets.” It will investigate a solid-particle based thermal energy storage (TES) module and one or more small supercritical carbon dioxide (sCO2) power cycle skids, with a goal of maximizing the heat transfer coefficient in the TES to transfer heat more efficiently to the embedded sCO2 pipes.