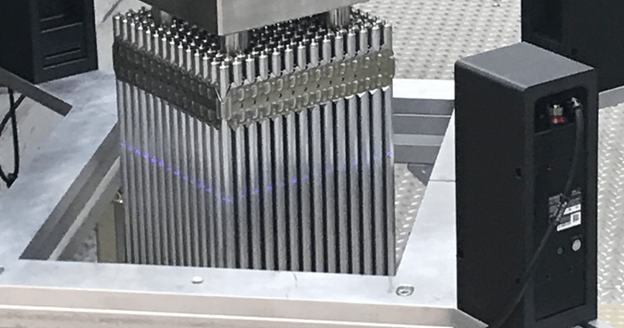

Framatome’s spray liner rehabilitates buried piping and underground components. (Photo: Framatome)

Framatome was recently awarded a multimillion-dollar contract to perform mitigation of buried condenser feed pipes at a three-unit nuclear power plant in the United States.

The France-based nuclear company plans to install spray-in-place structural pipe liner to mitigate more than one mile of large diameter underground piping connected to plant condenser boxes. The project will be performed during nine outages over eight years, with the first application planned for fall 2025.

The plant where the project will be performed was not named by Framatome, but the four U.S. plants with three operating units are Browns Ferry in Alabama, Oconee in South Carolina, Palo Verde in Arizona, and, most recently, Vogtle in Georgia—though its fourth unit is now in operation.

About the project: Buried pipes and underground components for nuclear power plant operations range in diameter from just a few inches to more than 10 feet. Aging and degradation of buried pipes is an industry challenge, given the difficulty and expense of accessing the components for repairs and inspections.

Framatome, working with industry partners, developed an engineered structural spray-in-place liner system to extend the life of buried piping beyond the original 50-year design life span and through to the end of plant life. The product is applied remotely using in-pipe robotic crawlers. It is sprayed evenly onto the inside of the pipe and cures quickly to fully rehabilitate the pipe, becoming the pipe’s new pressure boundary. The quick-installing system does not require excavation, thus minimizing safety risks, reducing outage durations, and costs.

In November 2023, Framatome announced the successful completion of its two-year testing program for the spray-in-place pipe liner. The testing and engineering evaluations were performed at the company’s Qualification and Testing Center in Virginia.

Quotable: “Framatome’s teams innovated to adapt an industrial solution and apply it to the nuclear industry in support of our customer’s long-term operational needs and competitiveness,” said Catherine Cornand, senior executive vice president for the Installed Base Business Unit at Framatome. “Now utility customers have access to an innovative, technically advanced, turnkey rehabilitation solution that includes in-depth engineering, manufacturing, application, project management, technical support and OEM [original equipment manufacturer] experience.”