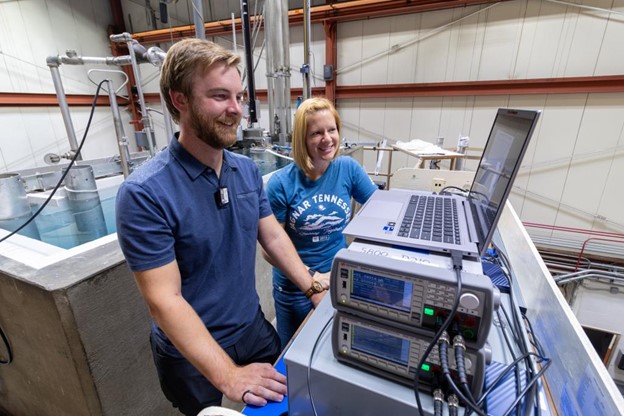

“We are showing it is great for this neutron environment,” said lead researcher Kyle Reed, a member of the Sensors and Electronics group at ORNL.

The problem and the solution: Sensors in the core of an operating power reactor provide early warnings about equipment wear so that preventative maintenance can be scheduled to avoid costly equipment failures. Currently, data from sensors must travel through yards of cabling before reaching electronics with silicon-based transistors in an area shielded from radiation.

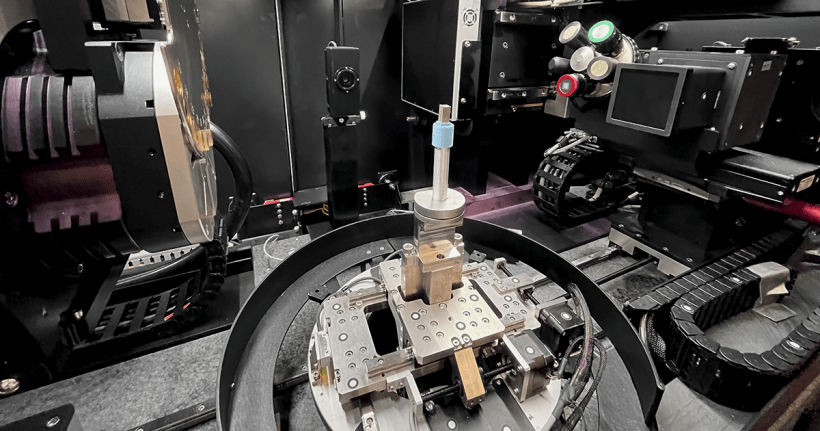

Devices with wide-bandgap semiconductors could operate at much higher frequencies, temperatures, and irradiation rates, according to ORNL, which means the electronics can be located closer to the reactor core.

“Our work makes measuring the conditions inside an operating nuclear reactor more robust and accurate,” Reed said. “When you have lengthy cables, you end up with a lot of noise, which can interfere with the accuracy of the sensor information. By placing electronics closer to a sensor, you increase its accuracy and precision.”

Electronics that can better tolerate radiation could be used in the fleet of light water reactors operating today, and would be even more valuable for compact advanced reactors and microreactors.

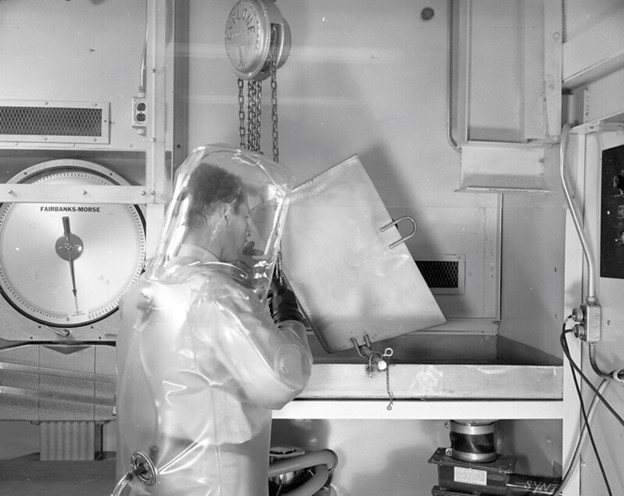

Experimental results: Suspecting that electronics made with gallium nitride could better tolerate radiation, researchers irradiated gallium nitride transistors for three days at temperatures up to 125°C close to the core of the Ohio State University research reactor.

The gallium nitride transistors were able to handle an accumulated dose of radiation at least 100 times higher than what a standard silicon device could withstand, according to Dianne Ezell, leader of ORNL’s Nuclear and Extreme Environment Measurements group and a member of the transistor research team.

Ezell said the transistor material must be capable of surviving at least five years “in the pool of a nuclear reactor.” After the research team exposed the gallium nitride devices to days of much higher radiation levels within a reactor core, they concluded that the transistors would exceed that requirement.

“We fully expected to kill the transistors on the third day, and they survived,” Reed said. The team pushed the transistors all the way to the reactor’s safety threshold: seven hours at 90 percent power.

Built and tested at Ohio State: Ohio State researchers built the test devices in different designs and sizes to meet specifications from ORNL, and then the team compared their responses to radiation, finding that larger devices seemed less susceptible to radiation damage. Ohio State is now developing computer models to project how various circuit designs will perform under different temperatures and radiation levels, according to ORNL.

Reed said the testing showed that gallium nitride was more vulnerable to heat than radiation, which is prompting new experiments to assess the performance of gallium nitride under conditions of heat without radiation. “Since the ultimate goal is to design circuits with these materials, once we understand the temperature and radiation effects, we can compensate for them in the circuit design,” Reed said.

Ultimately, the research team would like to develop gallium nitride circuits that could transmit data from sensors wirelessly.

The research project was funded by the Advanced Sensors and Instrumentation Program, and the irradiation was performed as part of a Rapid Turnaround Experiment funded by the Nuclear Science User Facilities Program. Both programs are part of the DOE’s Office of Nuclear Energy.