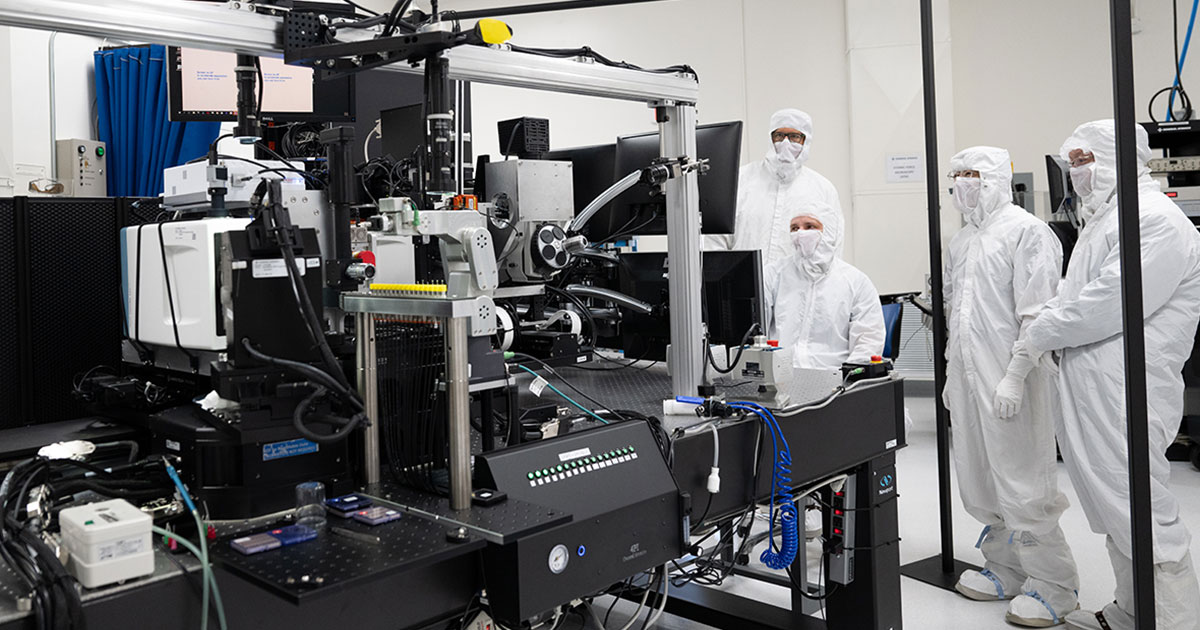

The 4Pi system: The 4Pi system uses robotics, automation, and machine learning to automate the examination of each target, measuring and screening each to map its properties, identify imperfections, and support improvements in the fabrication process. Abnormalities smaller than 1/100th the diameter of a human hair could prevent ignition, according to GA.

“We are overjoyed with the news of this recognition and are proud that our team has played a significant role in supporting successful ignition experiments at NIF,” said Haibo Huang, project lead for 4Pi and director of the Center of Excellence for Advanced Diagnostics and Sensors at GA. “Our goal is to create cutting-edge technologies that help overcome the most complex obstacles that ICF [inertial confinement fusion] scientists face to support national security missions and bring the world closer to achieving clean and limitless fusion energy.”

According to the award announcement from R&D World, the team led by Huang includes Kurt Boehm, engineering project manager; Kevin Sequoia, data scientist; and Pavel Lapa and Masashi Yamaguchi, instrumentation physicists.

“This award is a testament to the team’s hard work and commitment to developing game-changing technologies and capabilities for our field,” said Mike Farrell, vice president of inertial fusion technologies at General Atomics. “I am confident the 4Pi system will continue to play a significant role in assisting scientists to understand the fundamental principles to routinely and robustly produce fusion-ignition conditions.”

A closer look at 4Pi: GA’s 4Pi system combines up to eight instruments within one common coordinate system, including robotics, automation, batch evaluation, and machine learning technologies, to avoid measurement errors that can occur when a target is manually transferred from one instrument to another and identify the best targets from each production batch.

Two instruments on the 4Pi system specifically assisted in the recent ignition breakthroughs at NIF, according to GA. The digital holographic microscope spots defects on the surface of capsules that radiate heat away from the capsule’s “hot spot” and quench the fusion yield. The FTIR spectroscope maps variations in capsule wall thickness that can cause the hot spot to drift and deprive the yield. The system can fully measure and rank each target it tests.

In collaboration with NNSA, and on fusion energy: As the National Nuclear Security Administration’s primary commercial partner for ICF targets and target support services since 1991, GA provides more than 12,000 components annually for experiments conducted by NIF, the Z Pulsed Power Facility at Sandia National Laboratory, and the Omega Laser Facility at the Laboratory for Laser Energetics.

GA is also collaborating with private fusion companies and national laboratories on both magnetic confinement fusion and ICF energy programs. Most recently, GA received two 2024 INFUSE awards for work with Idaho National and Oak Ridge National Laboratories. GA has received other INFUSE awards and is participating in two IFE-STAR hubs, which were announced last December.