A non-aluminum spent nuclear fuel element. (Photo: DOE)

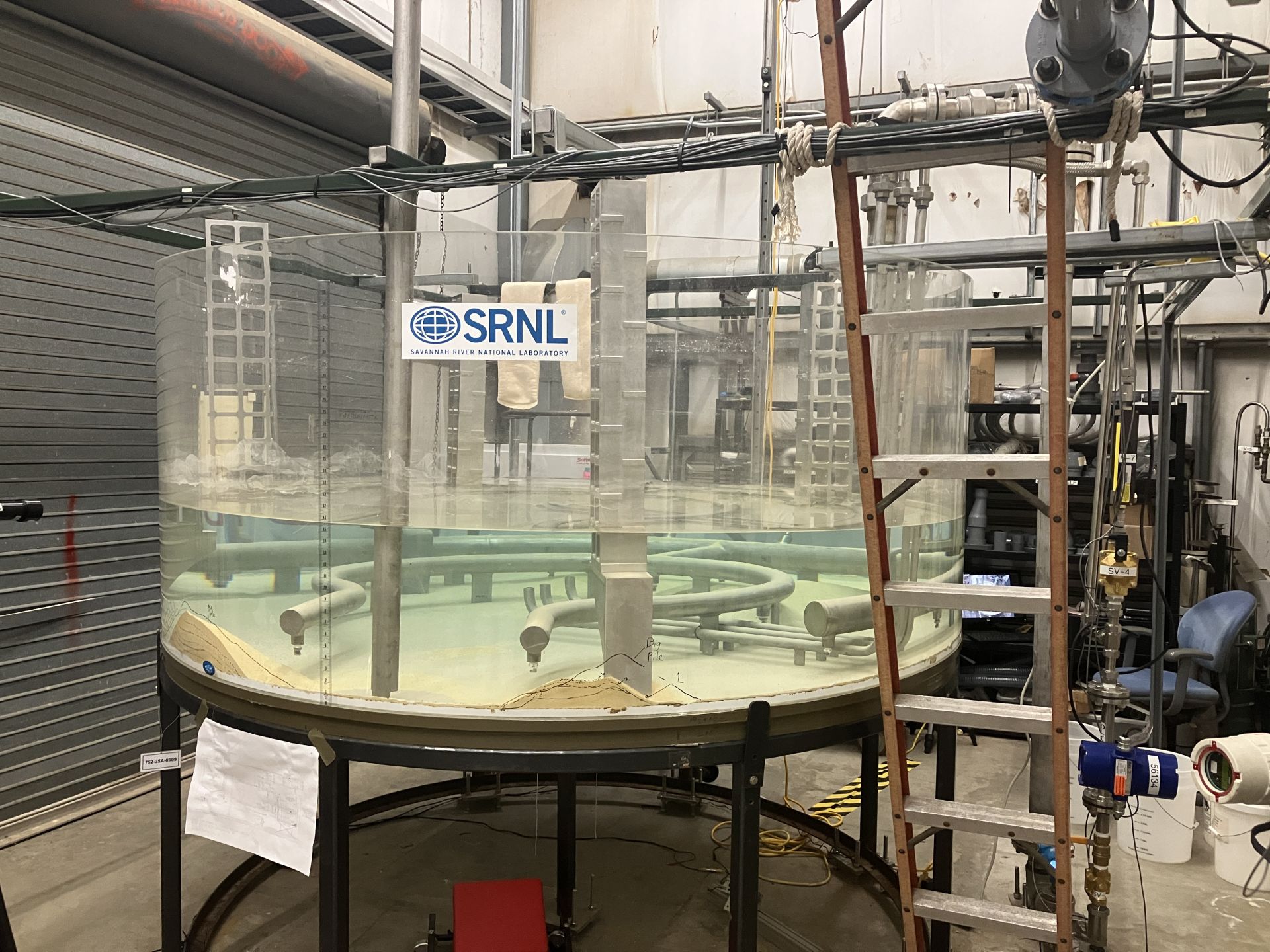

The inventory: Spent fuel stored in the site’s underwater storage L Basin is either clad in aluminum or a combination of zirconium and stainless steel and is referred to as NASNF. The L Basin inventory needs to be processed in the site’s H Canyon for permanent disposal in the coming years.

The makeup of the roughly 400 NASNF bundles in the L Basin varies in content, size, and composition, making some of it more challenging to dissolve, according to the DOE. Due to safety requirements, each different type of fuel requires a specific process. The origin of most NASNF is from historic test reactors, including one from SRS.

The plans: To process all remaining spent fuel in L Basin, the collaborative team has created the first set of NASNF dissolution flowsheets, which serve as plans for processing the fuel elements. The flowsheets specify things like chemical amounts, temperatures, and how the materials flow through the process.

“Having this first set of plans for processing a portion of the NASNF is a huge accomplishment, taking several years of technology development at SRNL,” said James Therrell, SRNL nuclear materials program manager.

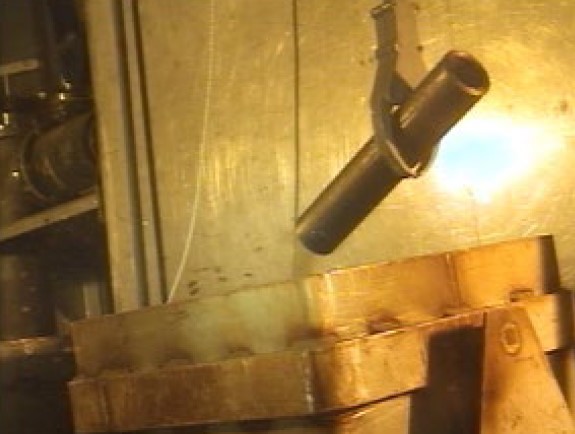

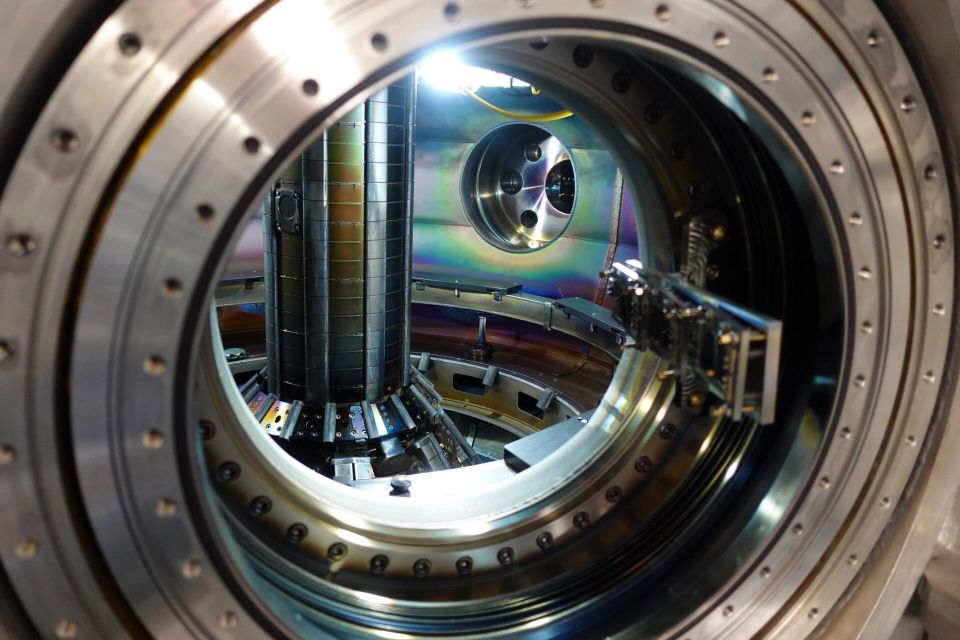

The processes: SRS will use an electrolytic dissolver to process the first set of NASNF. “While the aluminum-clad spent nuclear fuel can be chemically dissolved, a relatively easy process involving heating nitric acid to dissolve the aluminum, [the] zirconium-, and the stainless-steel-clad fuel is more challenging and must be electrolytically dissolved, adding electricity to the nitric acid dissolution process,” Therrell said.

The material will eventually be stabilized in a glass form by the site’s liquid waste contractor.

The strategies: According to the DOE, SRNL performed experiments to overcome challenges for the work, and SRNS developed strategies to prepare the fuel for use in the dissolver.

“SRNL has spent years evaluating and tackling the challenges of processing [the] NASNF,” said Tam Truong, SRNL researcher. “We have conducted electrolytic dissolution experiments and leveraged processing knowledge and experience to develop the dissolution parameters for the first group of NASNF.”

Truong continued, “As the process can generate insoluble or undissolved material, we have demonstrated a full-scale jet cleanout system to remove the undissolved material, allowing further dissolution to continue. The ongoing complementary collaboration between SRNL and SRNS strengthens our processing capabilities.”

Therrell concurred, saying, “SRNL developed an impressive residue cleanout prototype that has provided the essential data to allow the processing facilities to finalize equipment designs.”

An electrolytic dissolver at H Canyon can support NASNF missions in addition to H Canyon’s standard chemical dissolution capability.

“One of the intriguing aspects of this program is the historical significance of what these unique fuels provided to our country with regard to reactor designs and understanding,” Therrell said. “It feels good to be a part of a team that can help close the loop on these efforts.”