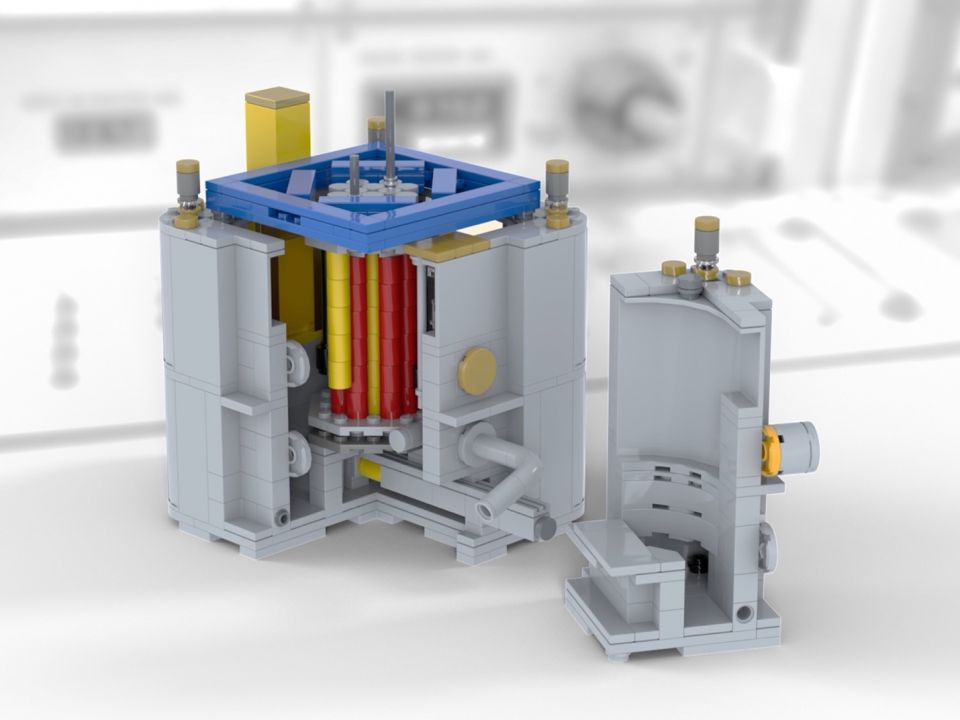

Cold neutron source: A key aspect of the upgrades was the replacement of OPAL’s cold neutron source (CNS), the component next to the core that reduces the speed and energy of neutrons as they travel through lines from the reactor to the neutron beam instruments at ANSTO’s Australian Center for Neutron Scattering (ACNS). This slow-down process allows researchers to examine the atomic structure of polymers and other materials in detail.

The CNS replacement was a major engineering undertaking. First, a full-size mockup of OPAL had to be built to carry out rehearsals, practice crane maneuvers, and conduct training sessions for replacement of the CNS.

During the actual replacement, the old CNS device and its associated pipework were carefully lifted out of OPAL and placed inside a shielded device with the aid of remotely operated cameras—and without any direct technician interaction. The new eight-meter-tall CNS structure then had to be installed vertically with a required positioning accuracy of only a few millimeters, again with the use of remote cameras. After the new CNS was positioned in place, the pipes suppling helium, deuterium, and vacuum services were connected and tested.

Enhanced analysis: The CNS upgrade will permit greater levels of scientific analysis. According to ACNS director Jamie Schulz, the replacement will boost the performance for eight of the center’s 15 neutron beam instruments. “The neutrons produced by OPAL support our unique facility and scientific instruments, allowing our researchers and industry partners to study the structure and dynamics of samples, such as molecules, polymers, proteins, and viruses,” He said.

Other upgrades: Another important aspect of the maintenance work performed at OPAL involved extensive upgrades to software and hardware in the first reactor protection system. This digital system, which monitors the reactor’s critical parameters, represents the first line of defense for automatically and safely shutting down the reactor if the parameters are exceeded.

Forward planning: The success of the maintenance and upgrade engineering project can be attributed to a decade-plus of intricate and sequential process planning, according to David Vittorio, general manager for OPAL.

Vittorio said, “OPAL is one of the most advanced and reliable research reactors in the world and is the centerpiece to some of ANSTO’s research and commercial operations at Lucas Heights [New South Wales]. Since OPAL commenced operations 17 years ago, we’ve been in a constant state of forward planning for regular, scheduled maintenance periods to ensure OPAL continues to operate safely, reliably, and efficiently.”

He added, “This planned shutdown has been the most significant maintenance and upgrade program in OPAL’s history to date. We’re very fortunate to have extensive engineering and maintenance expertise and decades of experience in running nuclear research reactors to accomplish these types of projects.”

Radioisotopes and silicon: The renewed operation of the renovated OPAL is great news for both the health and the electronics sectors. The reactor is used to produce neutrons that form the radioisotopes that are essential in nuclear medicine for diagnosing and treating patients with various cancers. OPAL is also used to meet more than half of the global demand for irradiated silicon, necessary in electronics and certain green technologies.