“Kairos Power is thrilled to continue expanding in New Mexico as we work to enable the world’s transition to clean energy,” said Kairos chief executive officer and cofounder Mike Laufer. “As global energy demand surges, we are driven by the imperative to move quickly in our mission. The pioneering capabilities and the incredible team we are celebrating today will make that possible.”

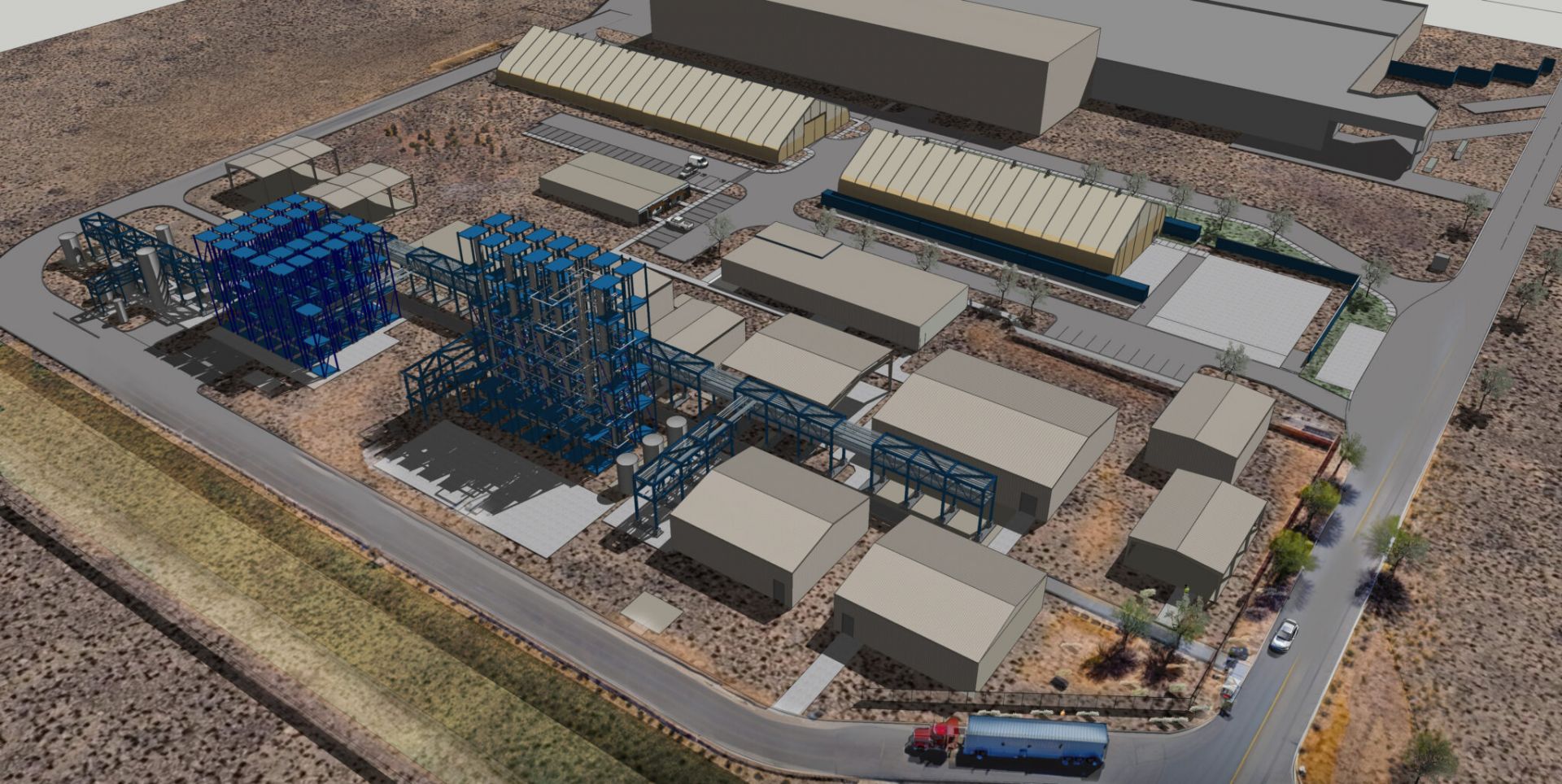

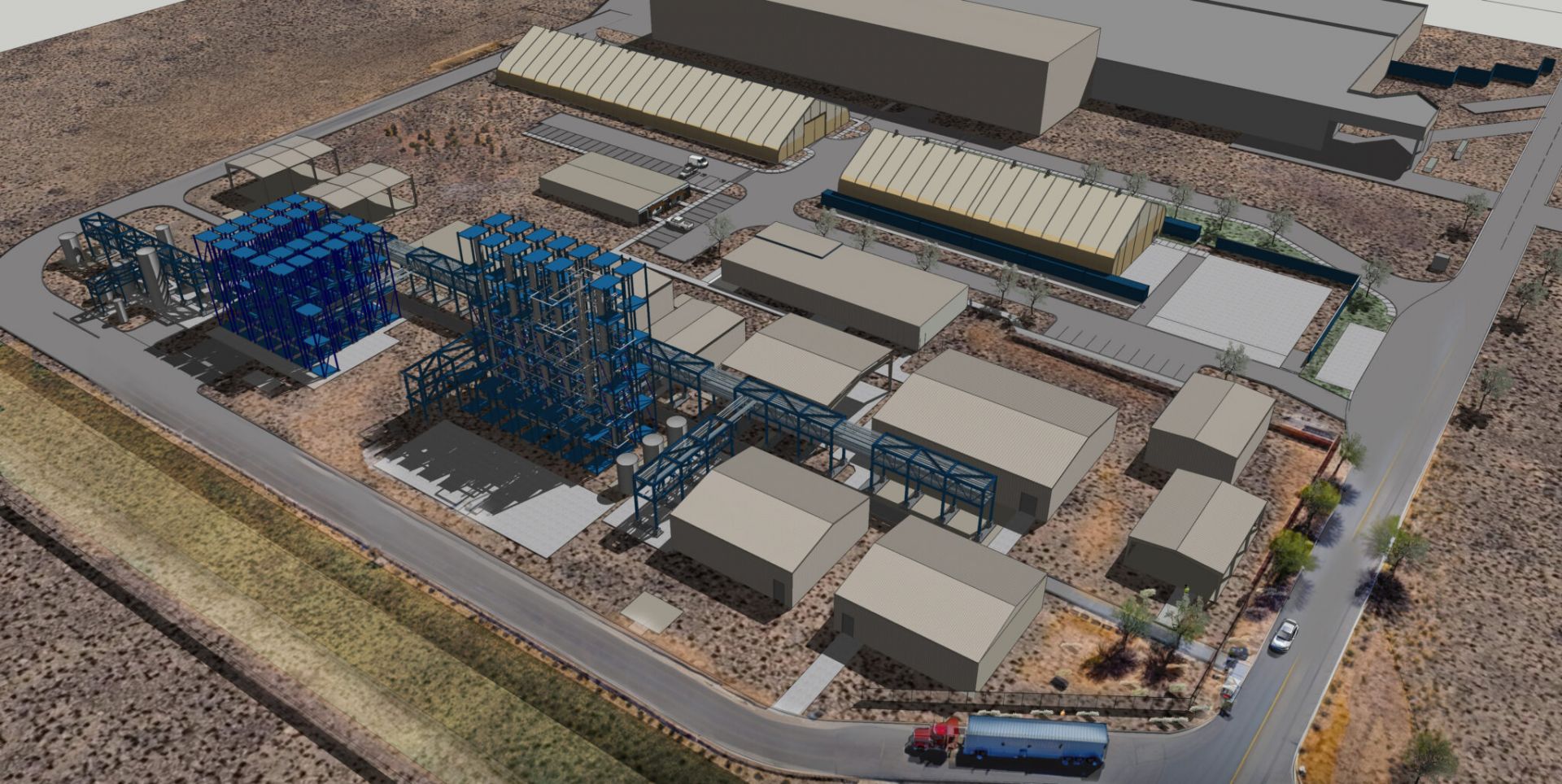

Rendering of the Salt Production Facility to be built at Kairos Power’s Manufacturing Development Campus in Mesa del Sol. (Photo: Kairos Power)

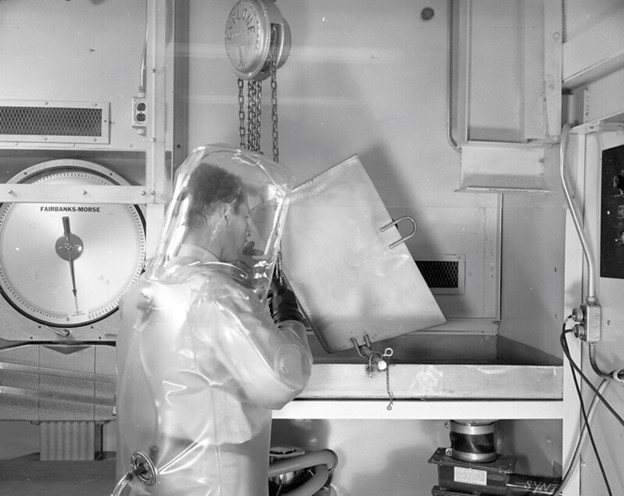

A plan for production: In Kairos Power’s fluoride salt–cooled high-temperature reactor technology (KP-FHR), FLiBe enriched in lithium-7 serves as the heat-transfer medium circulating through the reactor’s TRISO fuel pebbles containing high-assay low-enriched uranium (HALEU). The concept will be tested in Hermes, a nonpower demonstration reactor that received a construction permit from the Nuclear Regulatory Commission in 2023, followed by Hermes 2, which is nearing the end of its own licensing process. Construction began on Hermes in July.

“With the addition of molten salt coolant production, Kairos Power’s Manufacturing Development Campus will soon have all the capabilities we need to deliver the Hermes demonstration reactor and establish a credible path to scale up production for the commercial fleet,” said Kairos chief technology officer and cofounder Ed Blandford.

Kairos Power expects the construction and operation of the Salt Production Facility to create 20–30 full-time, high-paying jobs. The city of Albuquerque and the state of New Mexico are backing the project via economic incentives approved in September, and the project also makes use of funds from the Department of Energy’s Advanced Reactor Demonstration Program as well as private investment.

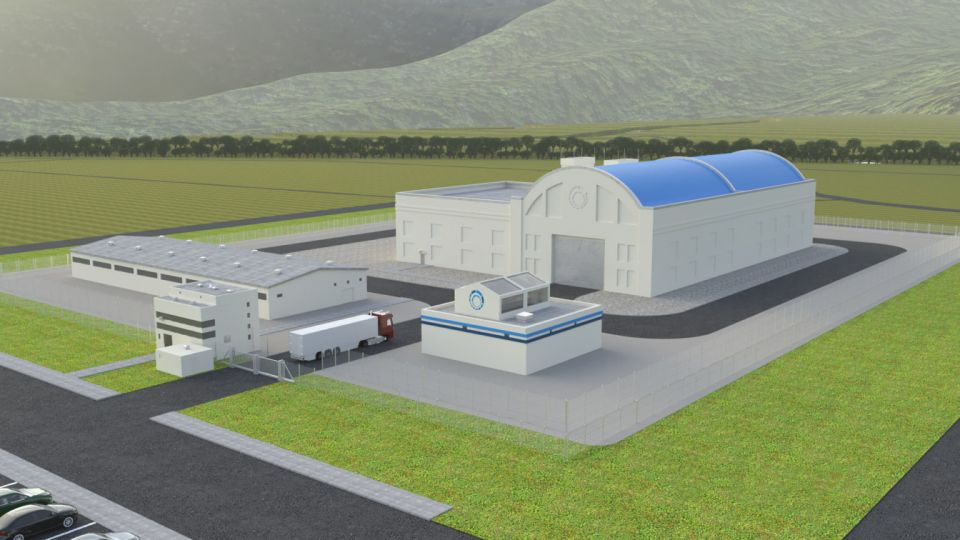

Aerial view of Kairos Power’s Manufacturing Development Campus at Mesa del Sol. Capabilities at the site include advanced reactor component manufacturing, U-stamped pressure vessel production, modular construction, welding, cutting, CNC machining, graphite pebble production, and large-scale, non-nuclear testing, with more on the way. (Photo: Kairos Power)

A first for FLiBe: The new Salt Production Facility is being built with an iterative approach similar to Kairos’s strategy for reactor development. It builds on “lessons learned from the company’s Molten Salt Purification Plant, which successfully produced 14 tons of unenriched FLiBe for the nonnuclear Engineering Test Unit (ETU 1.0) demonstration last year.” That plant was built in collaboration with Materion Corporation at Materion’s plant in Elmore, Ohio.

“The first-of-a-kind plant will enable future process optimization and establish the competency to scale up reactor-grade FLiBe production for the commercial fleet,” according to Kairos’s October 2 announcement. Using a vertical supply strategy for components and materials, Kairos hopes to mitigate supply chain risk and enhance cost and schedule certainty.

“This innovative facility establishes domestic production capacity for critical materials that will reduce our dependence on foreign suppliers,” said Alan Kruizenga, Kairos’s vice president for salt. “Building a domestic supply chain for FLiBe is a significant hurdle to clear, but we believe it’s achievable.”

A plaque commemorating the Manufacturing Development Campus dedication was produced in-house by Kairos Power machinists and unveiled during the ceremony. (Photo: Kairos Power)

Dedicated: On the same day Kairos Power broke ground on the Salt Production Facility, the company held a dedication ceremony for its Manufacturing Development Campus. Guests, including ANS executive director/CEO Craig Piercy and director of publications John Fabian, toured the company’s facilities and heard remarks from local, state, and federal leaders, including New Mexico governor Michelle Lujan Grisham and Sen. Martin Heinrich (D., N.M.).

Kairos Power was founded in 2016 and opened its Albuquerque location in 2020, acquiring a former solar panel factory and 32 acres of land to accommodate future expansion. In four years, the company says it has made over $125 million in capital investments at the site and has more than doubled its initial hiring plans. The site now has more than 130 full-time employees and hosts facilities for advanced reactor component manufacturing, U-stamped pressure vessel production, modular reactor construction, fuel fabrication process development, and large-scale nonnuclear testing with, according to the company, “more to come.”