DOE plans removal of naval prototype reactor, opens public comment period

The Department of Energy is proposing to fully decommission the Submarine 5th Generation General Electric (S5G) prototype at the Naval Reactors Facility on the Idaho National Laboratory site. Along with the Environmental Protection Agency and the state of Idaho, the DOE has initiated a 30-day public comment period (ending November 14) on the planned end state for the facility and its defueled reactor vessel.

Operating from 1965 to 1995, the S5G prototype facility provided a mock submarine used to train U.S. Navy personnel in naval nuclear propulsion plant operations and for research and development related to the Naval Nuclear Propulsion Program. To mitigate potential future risks associated with facility, the DOE is proposing to completely remove and dispose of the prototype and its defueled reactor vessel as part of a non–time-critical removal action under the Comprehensive Environmental Response, Compensation, and Liability Act.

Details of the DOE’s planned removal of the S5G prototype facility are provided in an engineering evaluation and cost analysis prepared by the DOE’s Idaho Operations Office.

Public meeting: An informational public briefing on the S5G engineering evaluation and cost analysis will be held during the Idaho Cleanup Project Citizens Advisory Board meeting on October 23 in Sun Valley, Idaho.

Information on participating in the meeting via Zoom can be found on the Idaho Environmental Coalition (IEC) website, along with links to providing comments on the planned end state for the S5G prototype facility.

The analysis: The Idaho Operations Office’s Engineering Evaluation/Cost Analysis for the Naval Reactors Facility S5G Final End State Including Disposition of Reactor Vessel (DOE/ID-12081) evaluates four alternatives for decommissioning the S5G prototype facility: a no-action alternative, continued surveillance and maintenance, in situ decommissioning, and complete prototype removal.

The DOE’s recommended action is the complete dismantling and removal of the facility, which includes the S5G prototype and its defueled reactor vessel, the subgrade hull basin housing the prototype, and nine subgrade cells within the S5G Test Plant Building.

According to the DOE, dismantling and removing the entire prototype would be a complete solution that would protect human health and the environment and would comply with environmental regulations. The cost of full removal is estimated to cost about $70.1 million.

The DOE contends that the continued surveillance and maintenance option offers no long-term protection and is not a viable option. Likewise, because contamination resulting from in situ decommissioning would remain, the DOE analysis found that long-term management and controls would be necessary. The in situ decommission option also would cost about $3.4 million more than complete removal.

The no-action alternative, said the DOE, is not protective of human health and the environment, but it was included in the analysis to provide a base case for comparison to the other alternatives.

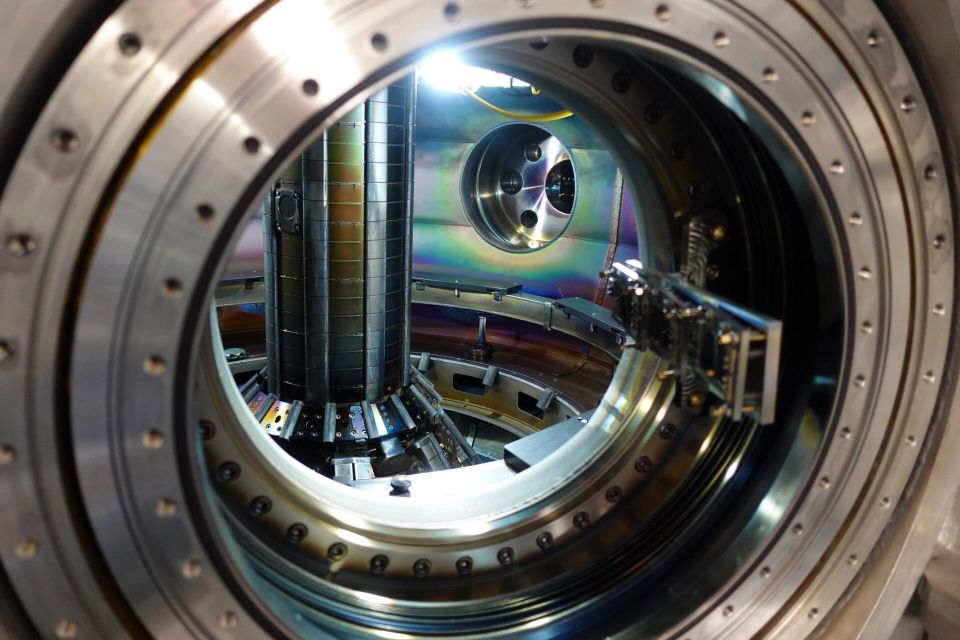

Idaho crews are completing final D&D work to the adjoining laboratories, office spaces, and hot cell that supported the S1W prototype during its operation. (Photo: DOE-EM)

Other efforts: The DOE’s Office of Environmental Management announced on October 15 that decontamination and demolition crews are currently making progress demolishing two additional defueled naval nuclear propulsion plant prototypes at INL’s Naval Reactors Facility using innovative technologies and techniques.

At the Aircraft Carrier 1st Generation Westinghouse (A1W) project, workers are using a sponge-blasting technology to remove paint containing polychlorinated biphenyls that was applied to facility equipment and components. According to DOE-EM, removal of the PCB paint allows the project to recycle metals and avoid disposal in landfills, while the sponge-blasting media is reusable, increases efficiency, and generates less waste than other paint removal processes.

Nearby at the Submarine 1st Generation Westinghouse (S1W) prototype, DOE-EM said D&D crews have restored a previously inoperable 125-ton overhead bridge crane to support removal of large steel components from the building. The restored crane has eliminated the need to hire a subcontractor to perform hoisting and rigging work, according to DOE-EM. In coming weeks, crews will remove critical components of the S1W, such as a hot cell and reactor vessel.

Idaho contractor IEC began D&D work on the S1W legacy naval nuclear propulsion plant prototype, including its defueled reactor vessel, in fiscal year 2022. This prototype served as a training ground for approximately 14,000 U.S. Navy submariners and plant operators. IEC anticipates completing the S1W project in fiscal year 2025 before completing D&D work at A1W.