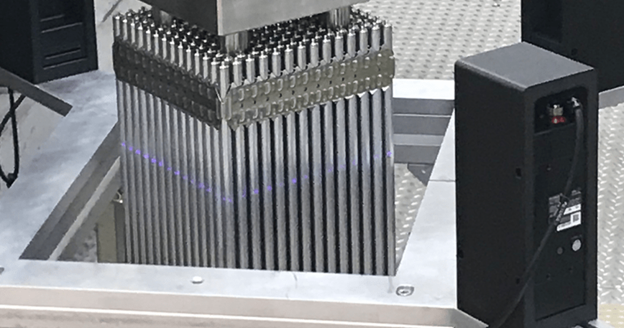

Framatome’s GAIA Protect EATF assembly. (Photo: Framatome)

Framatome’s enhanced accident tolerant fuel assemblies recently completed a third 18-month fuel cycle at Southern Nuclear’s Vogtle-2 plant—the first of this type of fuel to reach this milestone in the U.S., the company said.

Framatome’s GAIA fuel assemblies with Protect enhanced accident tolerant fuel (EATF) technology have operated over four and a half years since being inserted in 2019 at Vogtle, which concludes the full timeline assessment of the lead fuel assemblies concept and supports licensing activities to achieve market readiness.

“This is a significant milestone for our program, and through our collaboration with the U.S. Department of Energy and Southern Nuclear we bring this new and innovative technology one step closer to commercial operations,” said Lionel Gaiffe, senior executive vice president for the Fuel Business Unit at Framatome. “The success of this project demonstrates accident tolerant fuel readiness for the safe and reliable generation of our clean energy future.”

Government support: The DOE’s Office of Nuclear Energy awarded $111.2 million to Framatome, Westinghouse, and General Electric in 2019 earmarked for ATF fuel development. The DOE’s program aims to see advanced fuel concepts being brought to market by 2025.

This new breed of fuel further enhances nuclear fuel reliability and safety as well as the economics of nuclear reactor operations. The improved heat tolerance of ATF contributes to significantly improved reactor safety and security. ATF also improves economics because of its improved heat tolerance and increased agility to power reactors up and down while staying within safety margins.

A closer look: The four GAIA lead fuel assemblies are made of Framatome’s advanced chromium coating applied to zirconium alloy cladding, together with the chromia-enhanced fuel pellets. This design is meant to increase resistance to debris fretting, reduce the risk of fuel failure, and improve safety conditions for operators.

Each fuel assembly includes four lead test rods, for a total of 16 lead test rods with Framatome’s advanced chromium coating added to the M5 Framatome zirconium alloy cladding, and chromia-enhanced fuel pellets are included in all fuel assembly rods.