Partners: TerraPower’s manufacturing partners will be Equipos Nucleares S.A. (ENSA), producing the reactor head; Doosan Enerbility, supplying the core barrel, guard vessel, and internal supports for the Natrium reactor; HD Hyundai, manufacturing the reactor vessel; and Marmen, building the rotating plug.

Quotable: “The Natrium design is a game-changing technology, and assembling the right team of vendors to construct the first reactor speaks to TerraPower’s commitment to commercializing this technology and ensuring advanced nuclear fulfills its role in addressing surging global energy demand,” said Chris Levesque, TerraPower’s president and chief executive. “Our team continues to lead the way on successfully executing the many elements of building America’s next nuclear reactor.”

State of the project: The Natrium Reactor Demonstration Project is currently under construction in Kemmerer, Wyo. It is a public-private partnership under the umbrella of the U.S. Department of Energy’s Advanced Reactor Demonstration Program (ARDP).

Nonnuclear construction at the site began in June, while TerraPower worked in parallel to navigate the licensing and nuclear-specific construction permit process with the U.S. Nuclear Regulatory Commission.

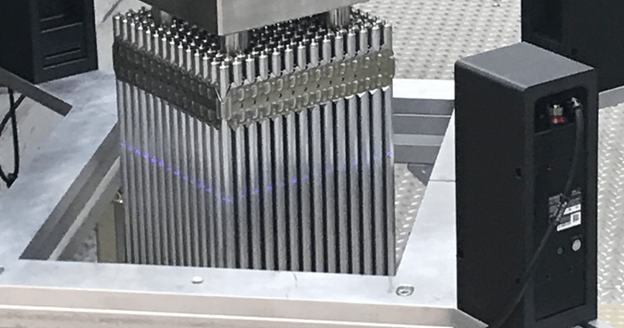

The technology: Natrium is a first-of-its-kind advanced reactor that uses liquid sodium as a coolant instead of water. The reactor offers improved fuel utilization, enhanced safety features, and a simplified design to reduce the overall materials needed to construct the plant, the company said.

The 345 MWe sodium-cooled fast reactor includes an integrated energy storage system that enables the plant to rapidly boost the system’s output to 500 MWe for more than five and a half hours, allowing for a seamless integration with renewable energy and an overall increase in grid resiliency.

The Natrium project offers dispatchable and flexible energy that will lead to faster, more cost-effective decarbonization of the electric grid while producing carbon-free power, according to the company.