Scott Forney (left), president of General Atomics Electromagnetic Systems and Mohamed Al Hammadi, managing director and CEO of ENEC. (Photo: General Atomics)

General Atomics announced last week that it will work with the Emirates Nuclear Energy Corporation to help find opportunities to support the United Arab Emirates.

Representatives from both companies signed a memorandum of understanding at the CERAWeek conference in Houston, Texas. The ENEC will work closest with General Atomics’ GA-EMS team, which develops new technologies and aims to deliver breakthrough solutions supporting environments from undersea to space.

Aerial photo of Warsaw city center in Poland.

The development of nuclear power is one of the pillars of Poland’s energy transition, which involves construction of safe and modern Generation III+ pressurized water reactors.

Polskie Elektrownie Ja˛drowe (PEJ) is the company responsible for, among other things, preparing the investment process for the construction of the first Polish nuclear power plant with a capacity of up to 3,750 MWe. PEJ’s goal is to build six nuclear reactors (for a total capacity of 6–9 GWe), securing 25 percent of the electricity needed in Poland by 2043 and guaranteeing a stable supply of clean energy to millions of homes across the country.

Government leaders gather on stage with IAEA director general Rafael Mariano Grossi at the Nuclear Energy Summit in Brussels on March 21.

International leaders and government representatives from nations that are operating or interested in operating nuclear power plants adopted a Nuclear Energy Declaration on March 21 at the first-ever Nuclear Energy Summit, hosted by the International Atomic Energy Agency and the Belgian government in Brussels, Belgium.

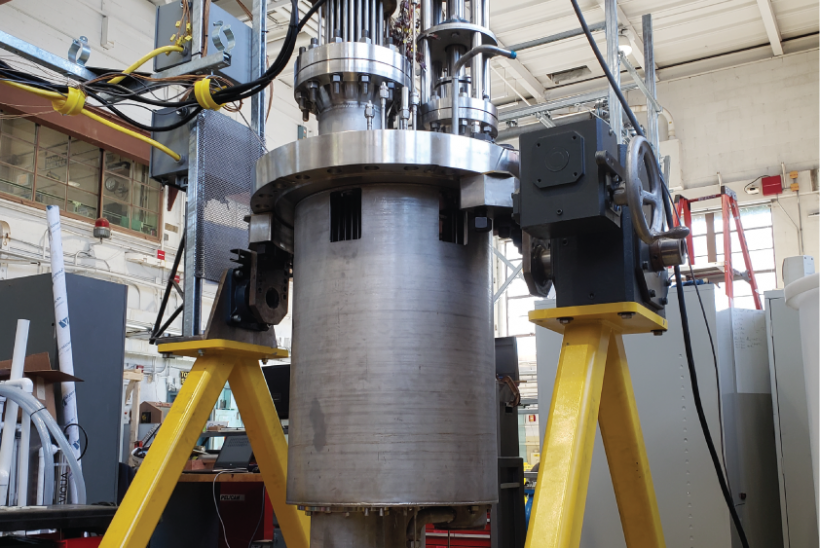

The primary system of THETA at Argonne’s Mechanisms Engineering Test Loop Facility, where Oklo is conducting sodium thermal-hydraulic testing with support from a GAIN award announced in 2021. (Image: Argonne National Laboratory)

The Department of Energy and the Gateway for Accelerated Innovation in Nuclear (GAIN) on March 19 announced the second round of fiscal year 2024 voucher awards to three companies: Element Factory, Kanata America, and Oklo.

X-energy employees gathered for a ribbon-cutting at its new training facility, Plant Support Center. (Photo: X-energy)

X-energy has opened a regional operations and training center aimed at supporting future deployment of its advanced modular nuclear reactor fleet and the operators who will run it.

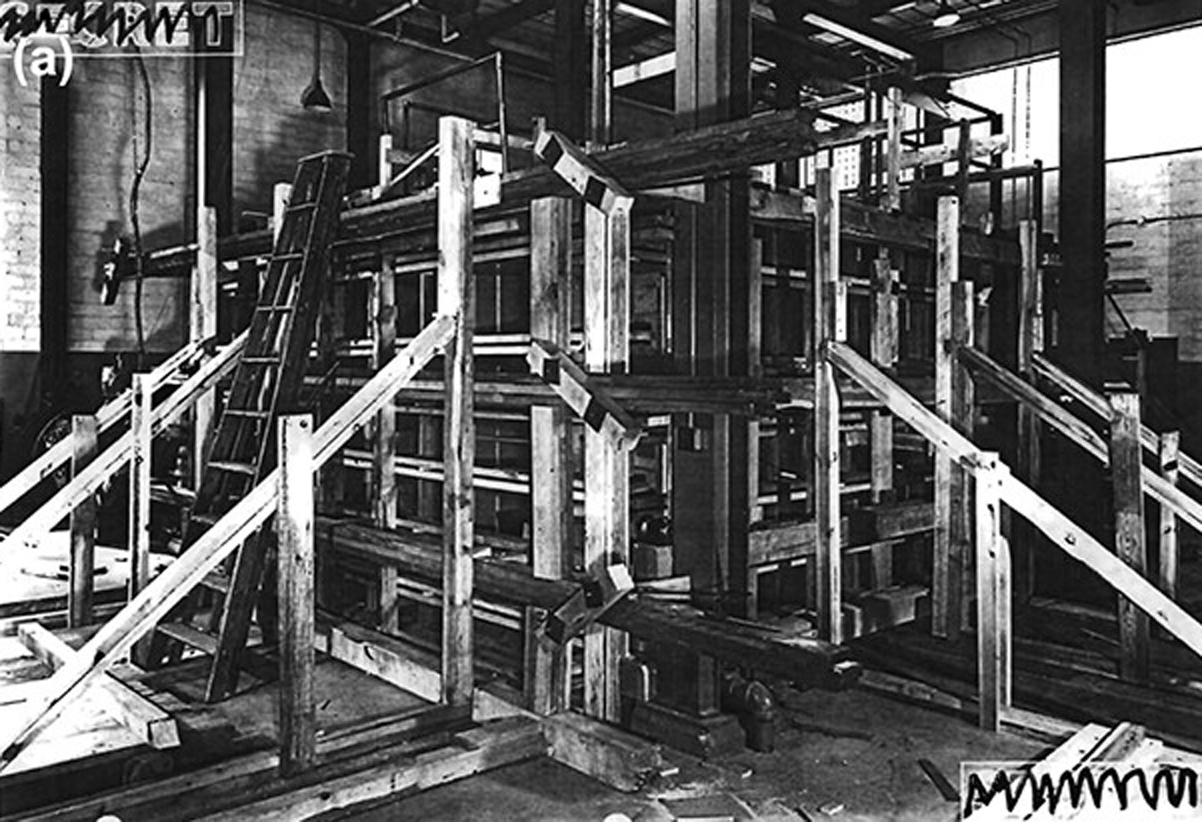

The exterior of the Clementine nuclear reactor at Los Alamos Scientific Laboratory. (Photo: LANL)

In March 1949—75 years ago this month—the 25-kilowatt reactor known as Clementine reached full power. As an experimental reactor, it had a rather long and successful run. It was the world’s first fast neutron (high-energy) reactor and operated from initial criticality in 1946 to final shutdown in 1952.

The Penn State RSEC recently received a SANS device. (Photo: Poornima Tomy/Penn State)

Staff and researchers at Penn State’s Radiation Science and Engineering Center (RSEC) will work this year to install a small angle neutron scattering (SANS) device and become the first and only U.S. university research reactor to host SANS capability. The $9.8 million device, donated by Helmholtz Zentrum Berlin (HZB) in Germany, will help researchers determine the structure of organic materials such as polymers, complex fluids, and biomolecules.

A view of Diablo Canyon nuclear power plant from the water. (Photo: California Coastal Commission)

The owners of the Diablo Canyon nuclear power plant plan to dredge a massive buildup of shoaled sediment from its seawater intake cove.

Pacific Gas and Electric spokesperson Suzanne Hosn said, “The dredging project in the Diablo Canyon marina will remove approximately 70,000 cubic yards of sediment to prevent circumstances that could impact the power plant’s cooling system. Dredging will take place for the first time since operations began because of a rapid increase in sediment.”

The extrusion in progress. (Photo: INL/Lightbridge)

Lightbridge Corporation announced today that it has reached “a critical milestone” in the development of its extruded solid fuel technology. Coupon samples using an alloy of zirconium and depleted uranium—not the high-assay low-enriched uranium (HALEU) that Lightbridge plans to use to manufacture its fuel for the commercial market—were extruded at Idaho National Laboratory’s Materials and Fuels Complex.