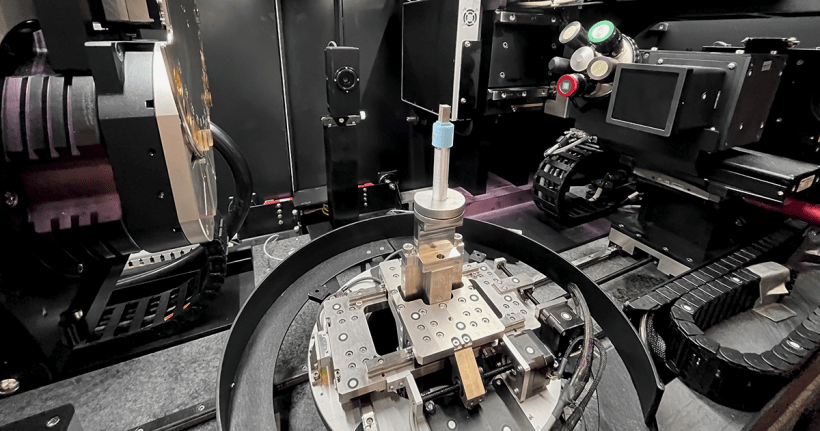

An enhanced CT scan process developed at ORNL can cut the time required to examine 3D-printed parts by one sixth. (Image: DOE)

A software algorithm developed at Oak Ridge National Laboratory has reduced the time needed to inspect 3D-printed parts for nuclear applications by 85 percent, the Department of Energy announced on November 1, and that algorithm is now being trained to analyze irradiated materials and nuclear fuel at Idaho National Laboratory.

The Susquehanna nuclear power plant. (Photo: Talen)

The Federal Energy Regulatory Commission has denied plans for Talen Energy to supply additional on-site power to an Amazon Web Services’ data center campus from the neighboring Susquehanna nuclear plant in Pennsylvania.

November 1, 2024, 3:02PMNuclear NewsClaire Pieper and Dan Scholz A fatigue management program is used at

Xcel’s Monticello nuclear plant. (Photo: Indeavor)

Fatigue has been identified as a major risk factor in industrial accidents. According to the National Safety Council, 13 percent of workplace injuries can be attributed to fatigue.1 Other research indicates that working 12 hours per day is associated with a staggering 37 percent increase in risk of injury.2 Considering fatigue was a contributing factor to major nuclear accidents at Chernobyl and Three Mile Island, it makes sense that the Nuclear Regulatory Commission imposes hefty fines to ensure strict adherence to its fatigue management regulations—particularly, Code of Federal Regulations Title 10, Part 26, “Fitness for Duty Programs.”

The cross-disciplinary AtomCraft team. (Photo: University of New South Wales)

Commercial nuclear power is illegal in Australia, and it has been since the 1990s. This past June, however, the country’s main opposition party announced plans to build seven commercial nuclear reactors in the 2030s and 2040s on sites presently occupied by aging coal-fired plants—should the party’s Liberal–National Coalition win power in federal elections next year. This statement has reignited a public debate regarding the potential role of nuclear energy in Australia.

Colorado State University hosted a ground-breaking event for a new laser research facility being built in partnership with Marvel Fusion at the university’s Foothills Campus. (Image: CSU)

In the foothills of the Rocky Mountains on the outskirts of Fort Collins, Colo.—home to Colorado State University—work began this month on a new laser facility funded by a public-private partnership. The private portion is $150 million from Marvel Fusion, announced in August 2023, while $12.5 million—the latest funding for CSU from the Department of Energy’s Office of Fusion Energy Sciences (FES)—will support the new facility as part of LaserNetUS, a laser research network operated by DOE-FES to provide access to laser facilities for multidisciplinary researchers from the United States and abroad.

October 25, 2024, 2:58PMNuclear NewsGeoffrey Campbell and Christopher Koehler The clevis bolt replacement team working in parallel off of the refueling bridge. This team is working directly on the reactor vessel clevis with a first-of-a-kind docking station. (Photo: Westinghouse)

Unit 2 at the Prairie Island nuclear power plant near Red Wing, Minn., underwent an outage in fall 2023, which included extensive work on the reactor vessel using a novel approach to replace baffle-former bolts and lower radial clevis insert bolts. The work relied on extensive analysis beforehand to determine which bolts to replace such that only the new bolts were structurally credited for performance of their safety function. This proactive approach eliminated the need for costly contingencies associated with inspections.

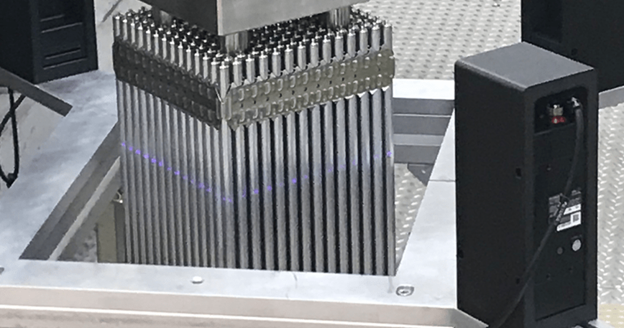

Framatome’s GAIA Protect EATF assembly. (Photo: Framatome)

Framatome’s enhanced accident tolerant fuel assemblies recently completed a third 18-month fuel cycle at Southern Nuclear’s Vogtle-2 plant—the first of this type of fuel to reach this milestone in the U.S., the company said.

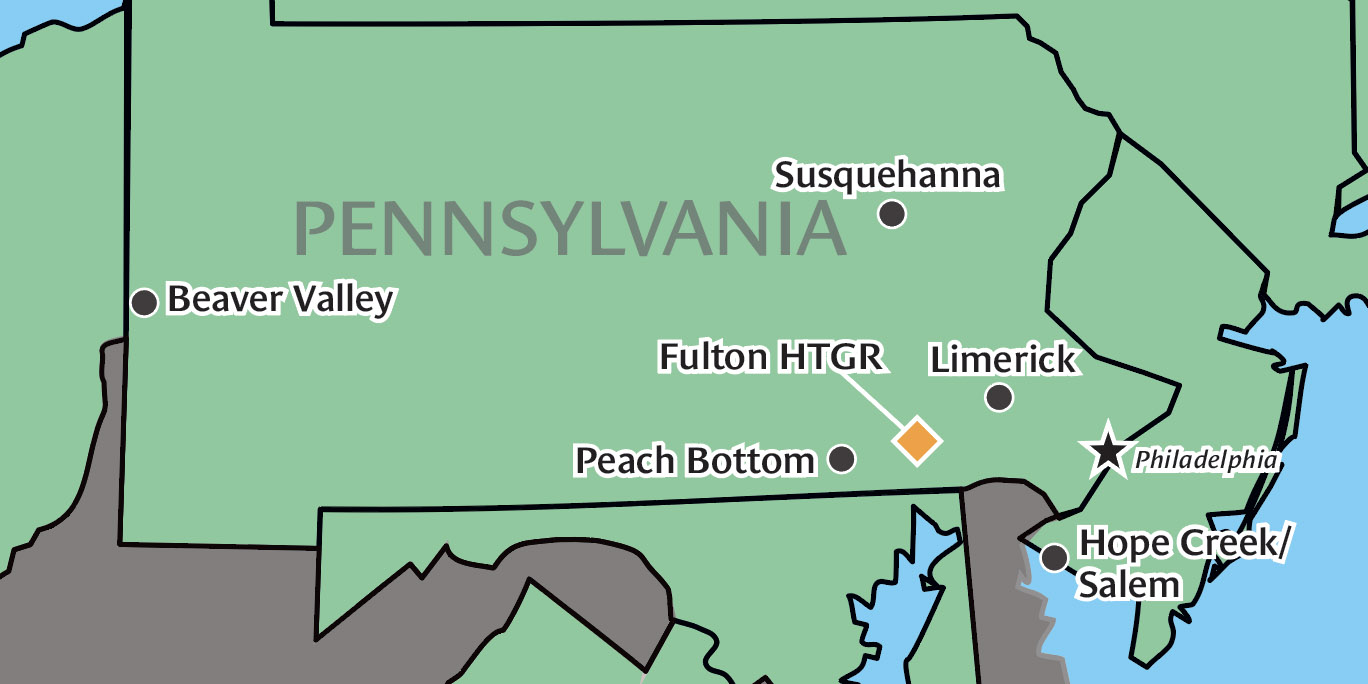

The once-proposed location of the Fulton HTGR, in relation to modern-day operating nuclear power plants.

Fulton Station was to be a two-unit high-temperature gas-cooled reactor that was originally planned to start commercial operation in 1981 for Unit 1 and in 1983 for Unit 2. Each reactor was to provide 1,160 MWe of power. The nuclear steam supply system (NSSS) and fuel were to be developed by General Atomics (GA), and engineering firm Stone & Webster was charged with handling the construction. The Philadelphia Electric Company (PECO) had big plans for Fulton Station, but ultimately, the plant was never built.