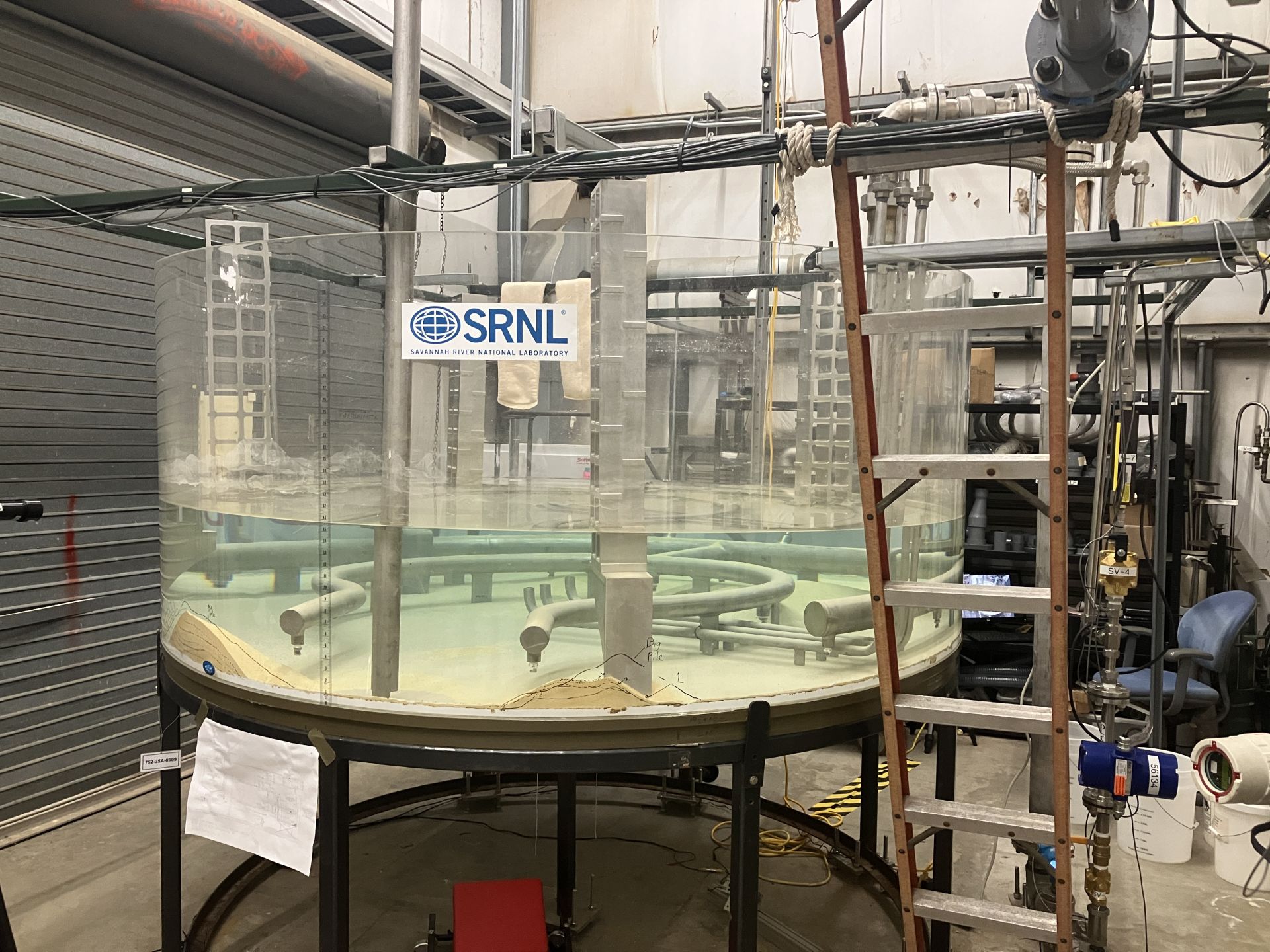

A mock-up model at SRNL was used to demonstrate a full-scale jet cleanout system to remove undissolved material from the H Canyon electrolytic dissolver. (Photo: DOE)

A collaboration between Savannah River Nuclear Solutions (SRNS) and Savannah River National Laboratory (SRNL) is making progress toward processing non-aluminum spent nuclear fuel (NASNF) as part of the site’s accelerated basin de-inventory mission. SRNL is the managing and operating contractor at the Department of Energy’s Savannah River Site in South Carolina.

The D Area Groundwater Treatability Study project team assesses artesian flow into injection well at the Savannah River Site. (Photo: SRNS)

Savannah River Nuclear Solutions (SRNS), the management and operations contractor for the Department of Energy’s Savannah River Site, announced that it has injected more than 100 million gallons of clean artesian well water to neutralize shallow groundwater contamination underneath 33 acres of a former coal storage yard and the associated runoff basin at the site in South Carolina. According to Ashley Shull, senior scientist for the project, “100 million gallons is nine times more water than [is] contained in the Georgia Aquarium in Atlanta.”

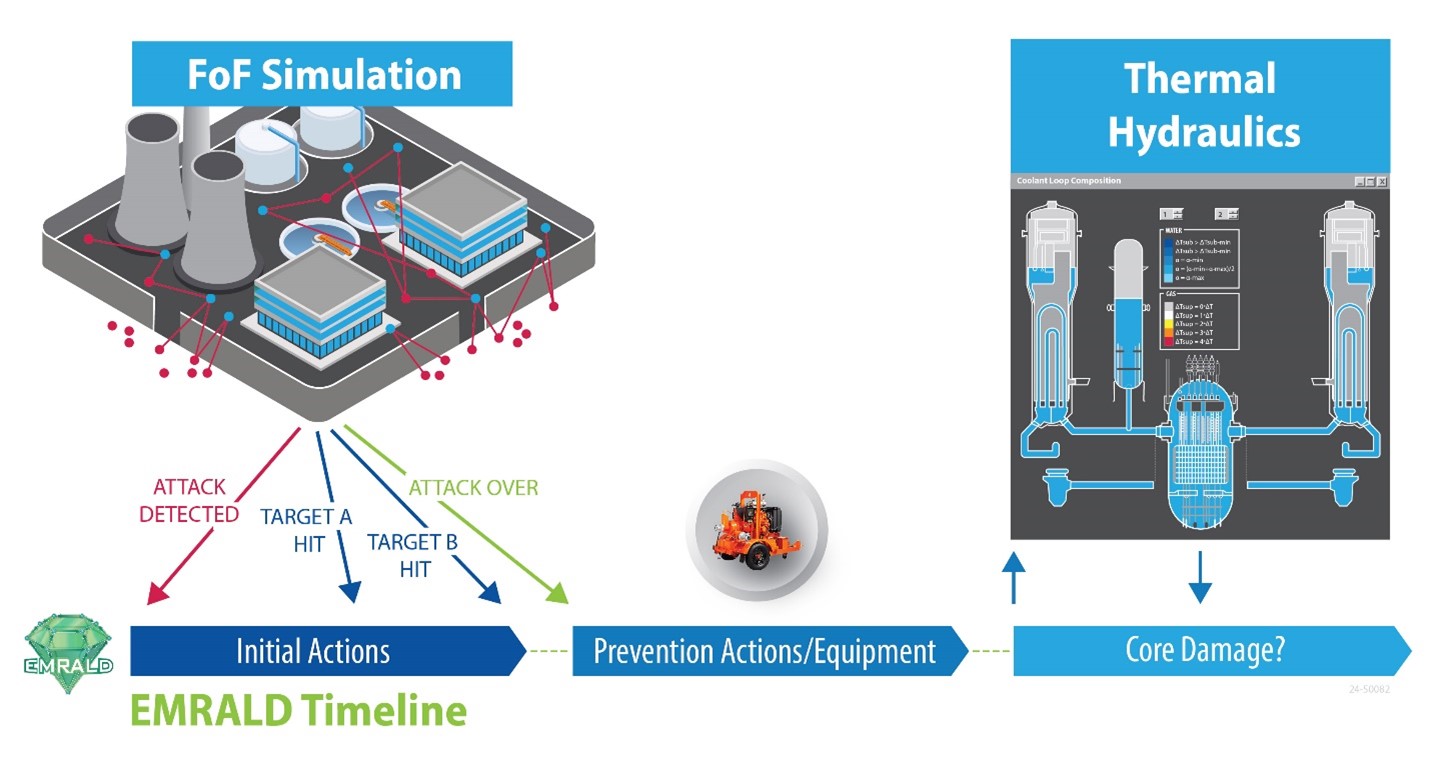

The MASS-DEF framework with prevention actions and timelines modeled in EMRALD software interacting with force-on-force (FoF) simulation and thermal hydraulics models. The risk-informed modeling in the MASS-DEF framework integrates physical security effectiveness analysis with safety measures, such as time to core damage. (Graphic: INL)

Today’s nuclear power plants are the nation’s largest source of carbon-free energy, but they come with high operating and maintenance costs.

Competition from other sources, especially natural gas, coupled with low electricity prices, has resulted in the closure of some plants in the last decade due to economic reasons.

One way to alleviate these economic pressures is to reduce the cost of operating nuclear power plants, including the costs associated with physical security.

Up-front requirements can enhance the ability to support maintenance and operations from start-up through long-term operation

It may seem counterintuitive, but the best time to enhance the ability to support operations and maintenance for a new plant is before construction starts. This is one of many lessons learned by the currently operating nuclear fleet. As construction and startup of many nuclear facilities was completed, it quickly became evident that the ability to efficiently support operations and maintenance was limited. Most of the information necessary to establish and manage procurement of spare and replacement items, maintenance, and configuration of the facilities was unavailable and had to be gathered on a case-by-case, “on-demand” basis. Absence of necessary information and the associated challenges resulted in the need for staff augmentation and multiyear-long projects to develop equipment bills of material and maintenance programs and to perform technical evaluations for the huge quantities of spare and replacement items being requested.

The OECD Nuclear Energy Agency’s William Magwood addresses the plenary audience of the 2024 Waste Management Conference in Phoenix. (Photo: WM Symposia)

Waste Management Symposia announced that the theme of next year’s Waste Management Conference (WM2025) will be “Empowering A Sustainable Future—Advanced Technologies, AI, and Workforce Development across the Nuclear Landscape.” To be held in Phoenix, Ariz., March 9–13, the conference will showcase how new technologies and the evolving digital world are transforming the global nuclear landscape, supply chains, infrastructure, and work norms.

The Paducah Site. (Photo: DOE)

The Department of Energy’s Office of Environmental Management has issued a final request for proposals for an infrastructure support services (ISS) contract at the department’s Paducah Site in Kentucky, which is the former home of the Paducah gaseous diffusion uranium enrichment plant. DOE-EM has conducted extensive cleanup and environmental remediation activities at the site since the late 1980s.

Teams use a 20-ton overhead crane to move the lower reactor vessel of the Oak Ridge Research Reactor into a cask for eventual shipment and disposal. (Photo: DOE)

Matthew Jasica is a member of a small team conducting large-scale experimental testing of reactors and their components at the NSTF. (Photo: Argonne)

A facility at Argonne National Laboratory has been simulating nuclear reactor cooling systems under a wide range of conditions since the 1980s. Its latest task, described by Argonne in an August 13 news release, is testing the performance of passive safety systems for new reactor designs.

Designed as a half-scale model of a real reactor system, Argonne’s Natural Convection Shutdown Heat Removal Test Facility (NSTF) is used for large-scale experimental testing of the performance of passive safety systems, which are designed to remove decay heat using natural forces including gravity and heat convection. Those tests yield benchmarking data qualified to the level of National Quality Assurance-1 (NQA-1) that is shared with vendors and regulators to validate computational models and guide licensing of new reactors and components.

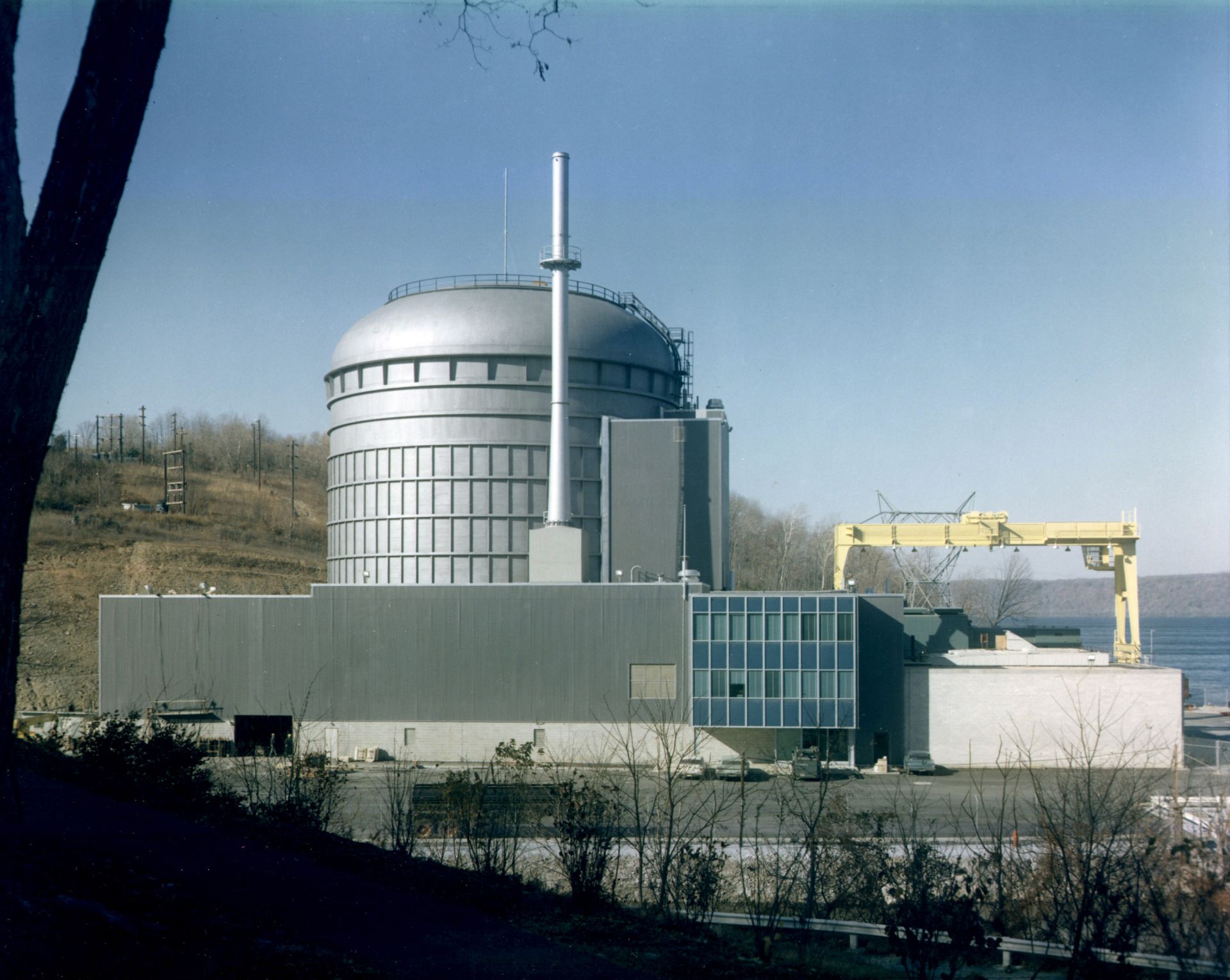

Peach Bottom Atomic Power Station, Unit 1. (Photo: NRC)

The first high-temperature, gas-cooled reactor ever built in the United States was Unit 1 at the Peach Bottom Atomic Power Station. This demonstration plant, located on the Susquehanna River approximately 80 miles southwest of Philadelphia, Pa., was tasked with validating HTGR design codes. It produced over 1.2 million megawatt-hours of electricity over 1,349 equivalent full-power days (EFPDs), which was distributed by the Philadelphia Electric Company.

The Bruce site currently hosts eight CANDU reactors. (Photo: Bruce Power)

As Bruce Power continues predevelopment work, public input is being sought on the potential Bruce C nuclear power expansion project in Ontario.

Bruce Power recently submitted its initial project description to the Impact Assessment Agency of Canada for an expansion that would add up to 4,800 MWe. Earlier this year, the Canadian government announced up to C$50 million ($36.8 million) in funding for the Bruce C project, which would be Canada’s first major expansion of a large nuclear plant in decades.

Students celebrate the first International Nuclear Science Olympiad. (Photo: INSO)

Fifty-five high schoolers representing 14 Asian countries participated in an inaugural nuclear science competition earlier this month in the Philippines.

The event was held in the run-up to the United Nations’ International Youth Day, which is celebrated worldwide on August 12 to recognize and encourage the potential of young people as active partners in the global society. The nuclear field presents many opportunities for the next generation of scientists and engineers.

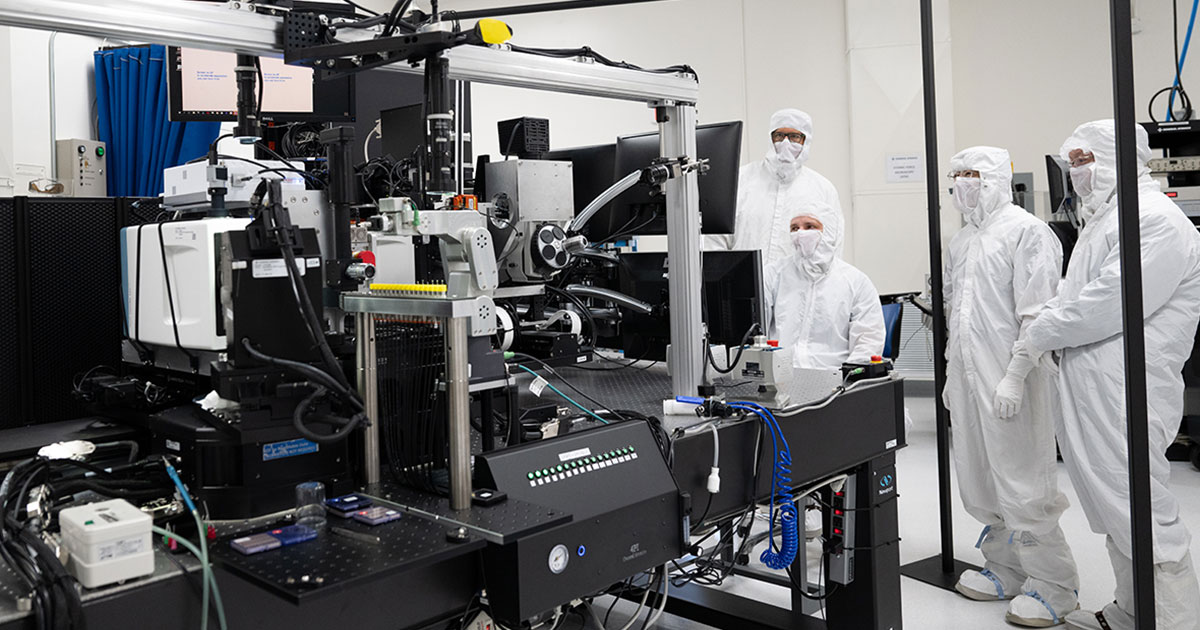

Members of the Metrology Research and Development team working with the 4Pi system in a clean room at GA headquarters. (Photo: General Atomics)

The National Ignition Facility (NIF) at Lawrence Livermore National Laboratory has achieved fusion ignition at least five times, each time by directing its 192 high-powered lasers on a capsule containing a tiny, 2-millimeter target filled with hydrogen fuel. Not every shot achieves ignition, however. Tiny imperfections in the targets can mean fizzle, not fusion. But each of the targets used in successful experiments to date have something in common: they were characterized and selected by the 4Pi Integrated Metrology System, a new measurement system developed by General Atomics. Now, the team behind that system is being recognized.

GA announced last week that its Metrology Research and Development team had won the 2024 "Team of the Year" R&D 100 Professional Award from R&D World. The magazine that each year announces the R&D 100 awards that have been dubbed the “Oscars of Innovation” also selects just one “Team of the Year” and announces that award together with four other professional awards.

The State of Ohio and

The State of Ohio and

QSA Global, a provider of radioisotope products, and Niowave, a Michigan-based producer of medical radioisotopes, announced that the companies will codevelop a scalable radium purification process using Niowave’s radium-226 processing technology to meet the demand for actinium-225, an alpha-emitter used in the treatment of cancer. According to the companies, the strategic partnership marks a significant advancement in the field of radiopharmaceutical technology, enhancing the supply chain for critical radioisotopes, including Ac-225.

QSA Global, a provider of radioisotope products, and Niowave, a Michigan-based producer of medical radioisotopes, announced that the companies will codevelop a scalable radium purification process using Niowave’s radium-226 processing technology to meet the demand for actinium-225, an alpha-emitter used in the treatment of cancer. According to the companies, the strategic partnership marks a significant advancement in the field of radiopharmaceutical technology, enhancing the supply chain for critical radioisotopes, including Ac-225.