TerraPower partnering with Sargent & Lundy in training center design

TerraPower has announced its selection of industry experts Sargent & Lundy to design the Kemmerer Training Center for its Natrium reactor demonstration project in Wyoming.

TerraPower has announced its selection of industry experts Sargent & Lundy to design the Kemmerer Training Center for its Natrium reactor demonstration project in Wyoming.

Federal regulators began an investigation this week at the Donald C. Cook nuclear plant around the circumstances of multiple diesel generator failures. The facility continues to operate safely.

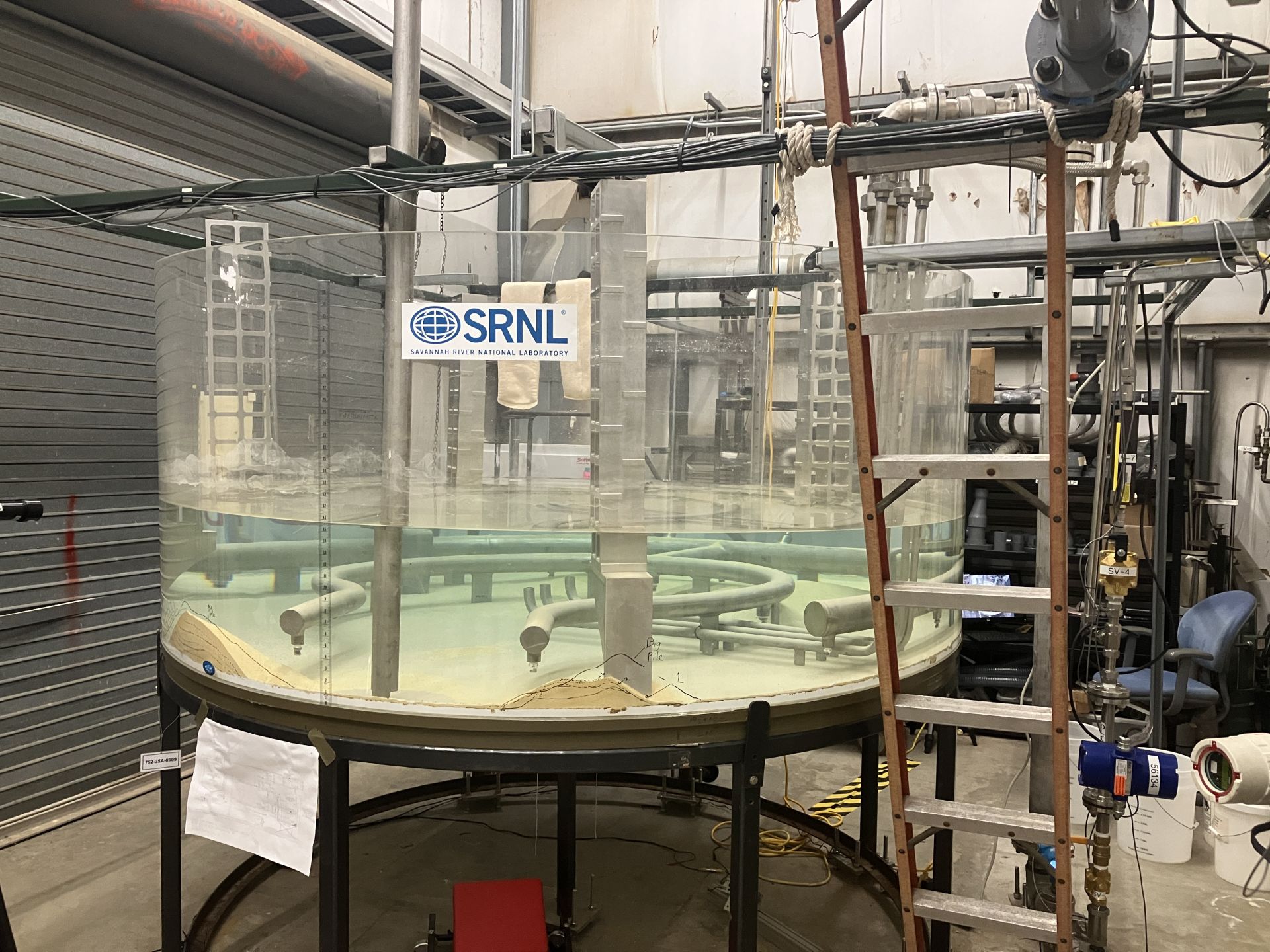

A collaboration between Savannah River Nuclear Solutions (SRNS) and Savannah River National Laboratory (SRNL) is making progress toward processing non-aluminum spent nuclear fuel (NASNF) as part of the site’s accelerated basin de-inventory mission. SRNL is the managing and operating contractor at the Department of Energy’s Savannah River Site in South Carolina.

Cesare Mencarini’s recent extended project qualification (EPQ) earned him an “A” for his studies in the United Kingdom—and became, it is believed, the first nuclear reactor built in a school environment.

Savannah River Nuclear Solutions (SRNS), the management and operations contractor for the Department of Energy’s Savannah River Site, announced that it has injected more than 100 million gallons of clean artesian well water to neutralize shallow groundwater contamination underneath 33 acres of a former coal storage yard and the associated runoff basin at the site in South Carolina. According to Ashley Shull, senior scientist for the project, “100 million gallons is nine times more water than [is] contained in the Georgia Aquarium in Atlanta.”

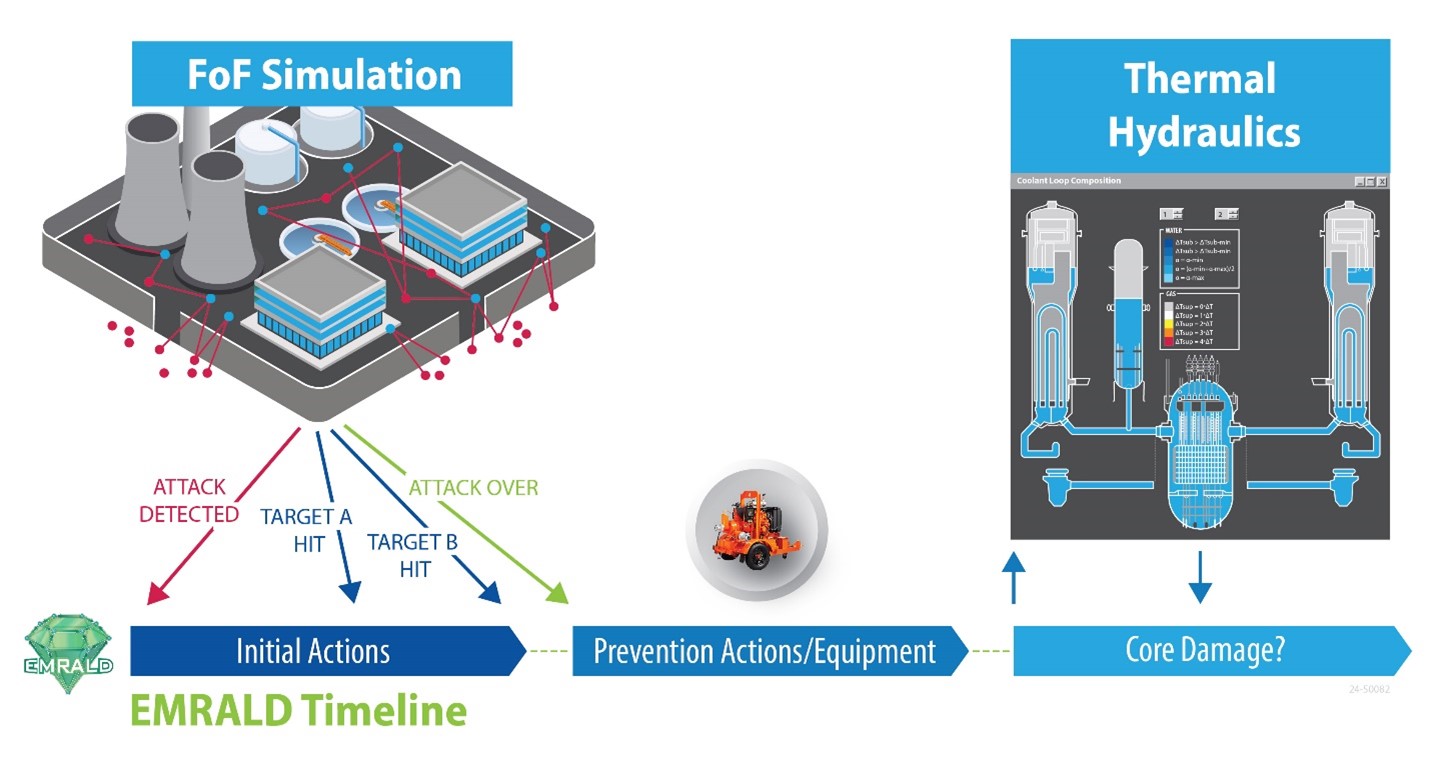

Today’s nuclear power plants are the nation’s largest source of carbon-free energy, but they come with high operating and maintenance costs.

Competition from other sources, especially natural gas, coupled with low electricity prices, has resulted in the closure of some plants in the last decade due to economic reasons.

One way to alleviate these economic pressures is to reduce the cost of operating nuclear power plants, including the costs associated with physical security.

Up-front requirements can enhance the ability to support maintenance and operations from start-up through long-term operation

It may seem counterintuitive, but the best time to enhance the ability to support operations and maintenance for a new plant is before construction starts. This is one of many lessons learned by the currently operating nuclear fleet. As construction and startup of many nuclear facilities was completed, it quickly became evident that the ability to efficiently support operations and maintenance was limited. Most of the information necessary to establish and manage procurement of spare and replacement items, maintenance, and configuration of the facilities was unavailable and had to be gathered on a case-by-case, “on-demand” basis. Absence of necessary information and the associated challenges resulted in the need for staff augmentation and multiyear-long projects to develop equipment bills of material and maintenance programs and to perform technical evaluations for the huge quantities of spare and replacement items being requested.

Waste Management Symposia announced that the theme of next year’s Waste Management Conference (WM2025) will be “Empowering A Sustainable Future—Advanced Technologies, AI, and Workforce Development across the Nuclear Landscape.” To be held in Phoenix, Ariz., March 9–13, the conference will showcase how new technologies and the evolving digital world are transforming the global nuclear landscape, supply chains, infrastructure, and work norms.

The Department of Energy’s Office of Environmental Management has issued a final request for proposals for an infrastructure support services (ISS) contract at the department’s Paducah Site in Kentucky, which is the former home of the Paducah gaseous diffusion uranium enrichment plant. DOE-EM has conducted extensive cleanup and environmental remediation activities at the site since the late 1980s.

Craig Harrington and Scott Palmtag are the newest members of the Advisory Committee on Reactor Safeguards.

They were appointed yesterday by the Nuclear Regulatory Commission to the independent advisory body tasked with reviewing safety studies and facility license applications. In addition, Walter Kirchner and Matthew Sunseri were reappointed.

The State of Ohio and FirstEnergy reached a settlement this week to avoid prosecution in an ongoing corruption investigation involving the Davis-Besse and Perry nuclear plants.

The State of Ohio and FirstEnergy reached a settlement this week to avoid prosecution in an ongoing corruption investigation involving the Davis-Besse and Perry nuclear plants.

In 2021, the U.S. Attorney’s Office for the Southern District of Ohio charged the energy company with conspiring “with public officials and other individuals and entities to pay millions of dollars to public officials in exchange for specific official action for FirstEnergy Corp.’s benefit.”

FirstEnergy will pay $19.5 million to the attorney general’s office within five business days and will pay $500,000 for an independent consultant to review and confirm unspecified “changes and remediation efforts” within the company. The company will also cooperate with investigators for two years or until the investigation, litigation, or prosecution is complete.

Team members at Oak Ridge National Laboratory achieved a milestone with the removal of a lower reactor vessel, according to a U.S. Department of Energy news release.

Workers with the Oak Ridge Office of Environmental Management (OREM) contractor UCOR successfully lifted and removed the lower reactor vessel from the Oak Ridge Research Reactor, also known as Building 3042.

A facility at Argonne National Laboratory has been simulating nuclear reactor cooling systems under a wide range of conditions since the 1980s. Its latest task, described by Argonne in an August 13 news release, is testing the performance of passive safety systems for new reactor designs.

Designed as a half-scale model of a real reactor system, Argonne’s Natural Convection Shutdown Heat Removal Test Facility (NSTF) is used for large-scale experimental testing of the performance of passive safety systems, which are designed to remove decay heat using natural forces including gravity and heat convection. Those tests yield benchmarking data qualified to the level of National Quality Assurance-1 (NQA-1) that is shared with vendors and regulators to validate computational models and guide licensing of new reactors and components.

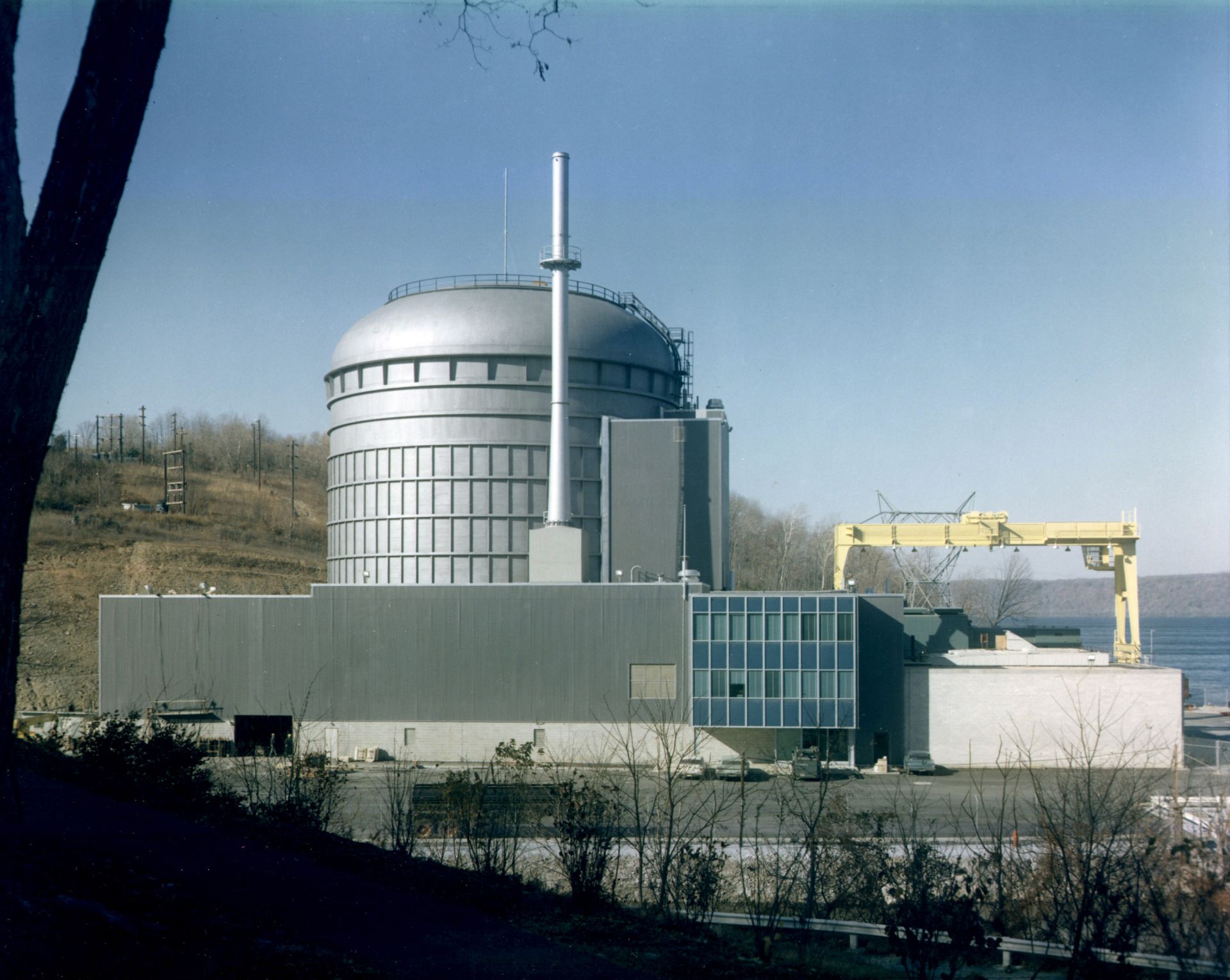

The first high-temperature, gas-cooled reactor ever built in the United States was Unit 1 at the Peach Bottom Atomic Power Station. This demonstration plant, located on the Susquehanna River approximately 80 miles southwest of Philadelphia, Pa., was tasked with validating HTGR design codes. It produced over 1.2 million megawatt-hours of electricity over 1,349 equivalent full-power days (EFPDs), which was distributed by the Philadelphia Electric Company.

QSA Global, a provider of radioisotope products, and Niowave, a Michigan-based producer of medical radioisotopes, announced that the companies will codevelop a scalable radium purification process using Niowave’s radium-226 processing technology to meet the demand for actinium-225, an alpha-emitter used in the treatment of cancer. According to the companies, the strategic partnership marks a significant advancement in the field of radiopharmaceutical technology, enhancing the supply chain for critical radioisotopes, including Ac-225.

QSA Global, a provider of radioisotope products, and Niowave, a Michigan-based producer of medical radioisotopes, announced that the companies will codevelop a scalable radium purification process using Niowave’s radium-226 processing technology to meet the demand for actinium-225, an alpha-emitter used in the treatment of cancer. According to the companies, the strategic partnership marks a significant advancement in the field of radiopharmaceutical technology, enhancing the supply chain for critical radioisotopes, including Ac-225.

Niowave uses a closed-loop cycle to produce high-purity Ac-225 and other alpha emitters from Ra-226 using a superconducting electron linear accelerator. According to the company’s website, the electron beam impinges on a photon converter to irradiate the Ra-226, inducing a photon-neutron reaction to Ra-225, which decays to Ac-225.

As Bruce Power continues predevelopment work, public input is being sought on the potential Bruce C nuclear power expansion project in Ontario.

Bruce Power recently submitted its initial project description to the Impact Assessment Agency of Canada for an expansion that would add up to 4,800 MWe. Earlier this year, the Canadian government announced up to C$50 million ($36.8 million) in funding for the Bruce C project, which would be Canada’s first major expansion of a large nuclear plant in decades.

The IAEA’s Milestones in the Development of a National Infrastructure for Nuclear Power was last revised back in 2015. Now, about nine years later and amid a resurgence of interest in nuclear power, the latest guidance on the IAEA’s Milestones Approach offers updated advice to policymakers in nations looking to introduce a nuclear power program or expand an existing fleet, encouraging them to evaluate infrastructure readiness before seeking bids from reactor vendors. For the first time, the guide includes an “annex” specific to small modular reactor deployments.

Ohio Gov. Mike DeWine recently made new appointments—including American Nuclear Society members Raymond Cao of Ohio State University and Alicia Walls of BWX Technologies—to the Ohio Nuclear Development Authority.

The nine-member governor-appointed board was created in June 2023 by state lawmakers aimed at boosting research and development of advanced nuclear reactors, commercial isotope production, and nuclear waste reduction and storage technology. The group has initial funding of $750,000.

Fifty-five high schoolers representing 14 Asian countries participated in an inaugural nuclear science competition earlier this month in the Philippines.

The event was held in the run-up to the United Nations’ International Youth Day, which is celebrated worldwide on August 12 to recognize and encourage the potential of young people as active partners in the global society. The nuclear field presents many opportunities for the next generation of scientists and engineers.

The OPTIMUS-H transportation cask from NAC International. (Photo: NAC)

NAC International announced that the Nuclear Regulatory Commission has certified a highly shielded version of the company’s OPTIMUS (Optimal Modular Universal Shipping) transportation package for radioactive materials and waste. NAC’s OPTIMUS-H is now approved under 10 CFR Part 71 with Certificate of Compliance (CoC) USA/9392/B(U)F-96, effective Aug. 5, 2024.

The OPTIMUS-H CoC follows licensing approvals of the cask in Canada and Australia. Previously, the lightweight version of the OPTIMUS package, OPTIMUS-L, received certification from the NRC and the Canadian Nuclear Safety Commission.

NAC unveiled its first OPTIMUS to the public at the 2020 Waste Management Conference in Phoenix. Since then, NAC has delivered 22 OPTIMUS-L and nine OPTIMUS-H systems to support North American packaging and transportation projects.