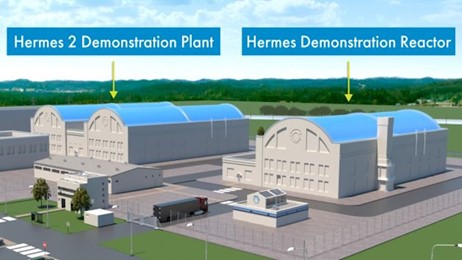

Workers begin construction at the Hermes site in Oak Ridge, Tenn. (Photo: Kairos Power)

Earlier today, on a site in Oak Ridge, Tenn., that was formerly home to the K-33 Gaseous Diffusion Plant, Kairos Power marked the start of construction on its low-power demonstration reactor. Named Hermes, the 35-MWt test reactor claims status as the first Gen IV reactor to be approved for construction by the Nuclear Regulatory Commission and the first non–light water reactor to be permitted in the United States in more than 50 years.

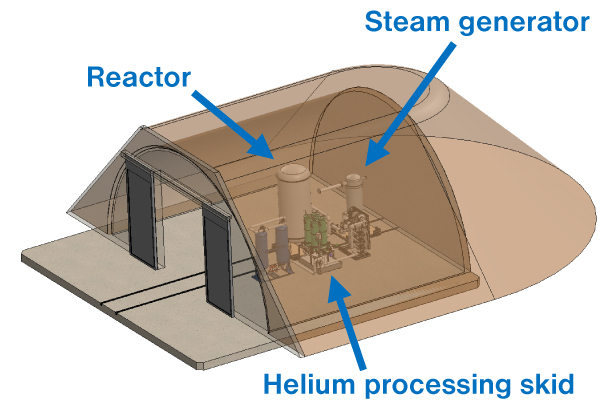

Concept art of the planned X-energy helium test facility. (Image: DOE OCED)

The Department of Energy’s Office of Clean Energy Demonstrations issued a final environmental assessment (EA) and finding of no significant impact in February for a cost-shared X-energy project to construct and operate a helium test facility (HTF) in Oak Ridge, Tenn. According to the EA, construction would begin in early 2024 and take X-energy and its contracted partner, Kinectrics, about one year to complete. the facility would then operate for six years, with the possibility of extensions for up to an additional 20 years, to test equipment for a demonstration of X-energy’s high-temperature, gas-cooled reactor technology and also to “serve the reactor community at large as the technology continues to develop and is adopted around the world.”

Image from the DOE’s draft EA showing a rendering of the TFF building. (Image: DOE)

The Department of Energy’s Office of Clean Energy Demonstrations issued a draft environmental assessment (EA) in early November for a test and fill facility (TFF) that TerraPower plans to build in Kemmerer, Wyo.—the town selected two years ago to host the company’s first Natrium sodium fast reactor. The draft EA, open for comment through December 1, describes TerraPower’s plans to construct a nonnuclear facility that would safely store about 400,000 gallons of sodium to test coolant system designs and ultimately fill the planned reactor.

A digital rendering of the Dow/X-energy Xe-100 plant in Texas. (Image: X-energy)

Dow and X-energy have announced the location of their Xe-100 small modular reactor deployment project: Dow’s UCC Seadrift Operations manufacturing site in Texas. According to a May 11 joint news release, the SMR plant will provide the Seadrift site with power and heat as the site’s existing energy and steam assets near the end of their operational lives.

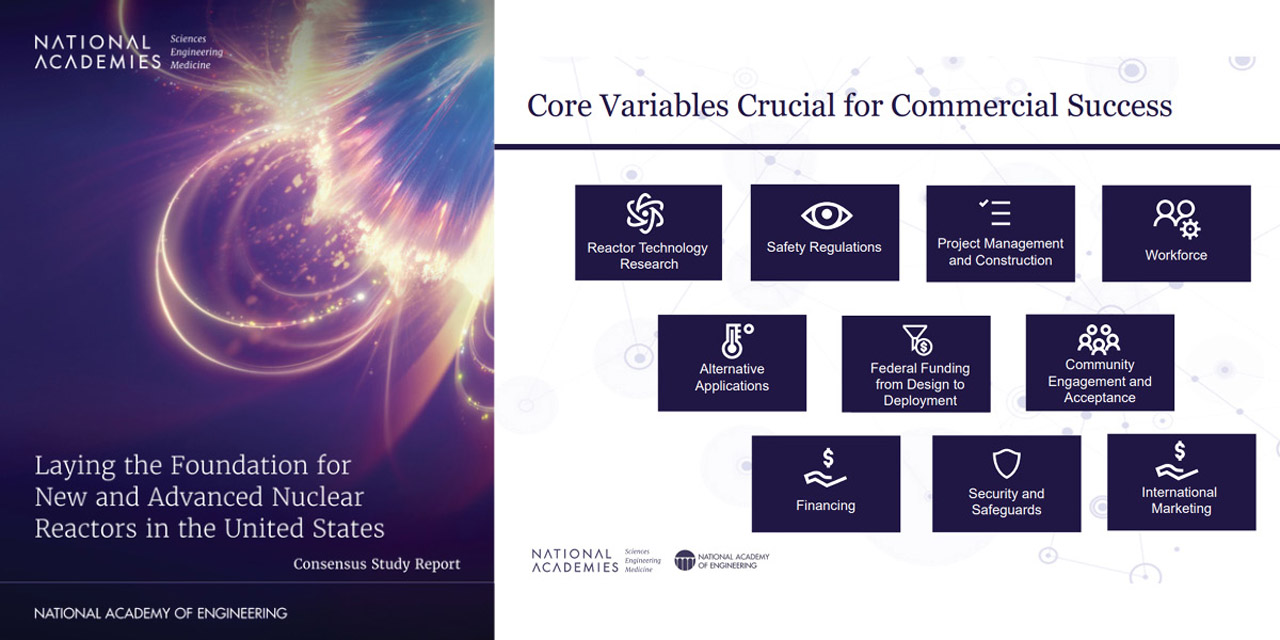

This slide on the right from the consensus committee’s public briefing identifies 10 core variables that are important to the success of advanced reactor deployments. (Image: NASEM, Laying the Foundation for New and Advanced Nuclear Reactors in the United States)

Artist’s rendering of an Xe-100 plant. (Image: X-energy)

Dow and X-energy announced today that they have signed a joint development agreement (JDA) to demonstrate the first grid-scale advanced nuclear reactor at an industrial site in North America within a decade. As part of the agreement, Dow is now a subawardee under X-energy’s Advanced Reactor Demonstration Program (ARDP) Cooperative Agreement with the Department of Energy.

A rendering of the TRISO-X fuel fabrication facility. (Image: DOE)

The Nuclear Regulatory Commission recently presented its proposed 30-month licensing review timeline of TRISO-X’s planned fuel fabrication facility at the project’s first-ever public meeting in Oak Ridge, Tenn.

TRISO-X, a subsidiary of X-energy, has requested a 40-year license to possess and use special nuclear material to manufacture advanced fuel. The facility would be the first-ever commercial-scale fuel fabrication plant focused on using high-assay low-enriched uranium (HALEU).

Industry professionals visit INL as part of a U.S. Nuclear Industry Council Conference. (Photo: INL)

The Department of Energy’s commitment to breaking down market barriers with initiatives, programs, and access to facilities is making it simpler and more efficient than ever for industry to partner with national laboratories. It is especially timely, as the country continues to face evolving security, economic, and clean energy challenges. Partnering opportunities via the DOE’s Cooperative Research and Development Agreements (CRADAs) and Strategic Partnership Projects (SPPs) are particularly prevalent in the commercial nuclear community and have seen a tremendous amount of funding and support dedicated to advancing the development, demonstration, and deployment of new reactor technologies.

Natrium Fuel Facility groundbreaking. (Photo: GNF-A)

Global Nuclear Fuel–Americas (GNF-A) and TerraPower announced their plans to build a Natrium fuel fabrication facility next to GNF-A’s existing fuel plant near Wilmington, N.C, on October 21. While more than 50 years of fuel fabrication at the site have supported the boiling water reactor designs of GE (GNF-A’s majority owner) and GE Hitachi Nuclear Energy (GEH), the Natrium Fuel Facility will produce metallic high-assay low-enriched uranium (HALEU) fuel for the sodium fast reactor—Natrium—that TerraPower is developing with GEH.

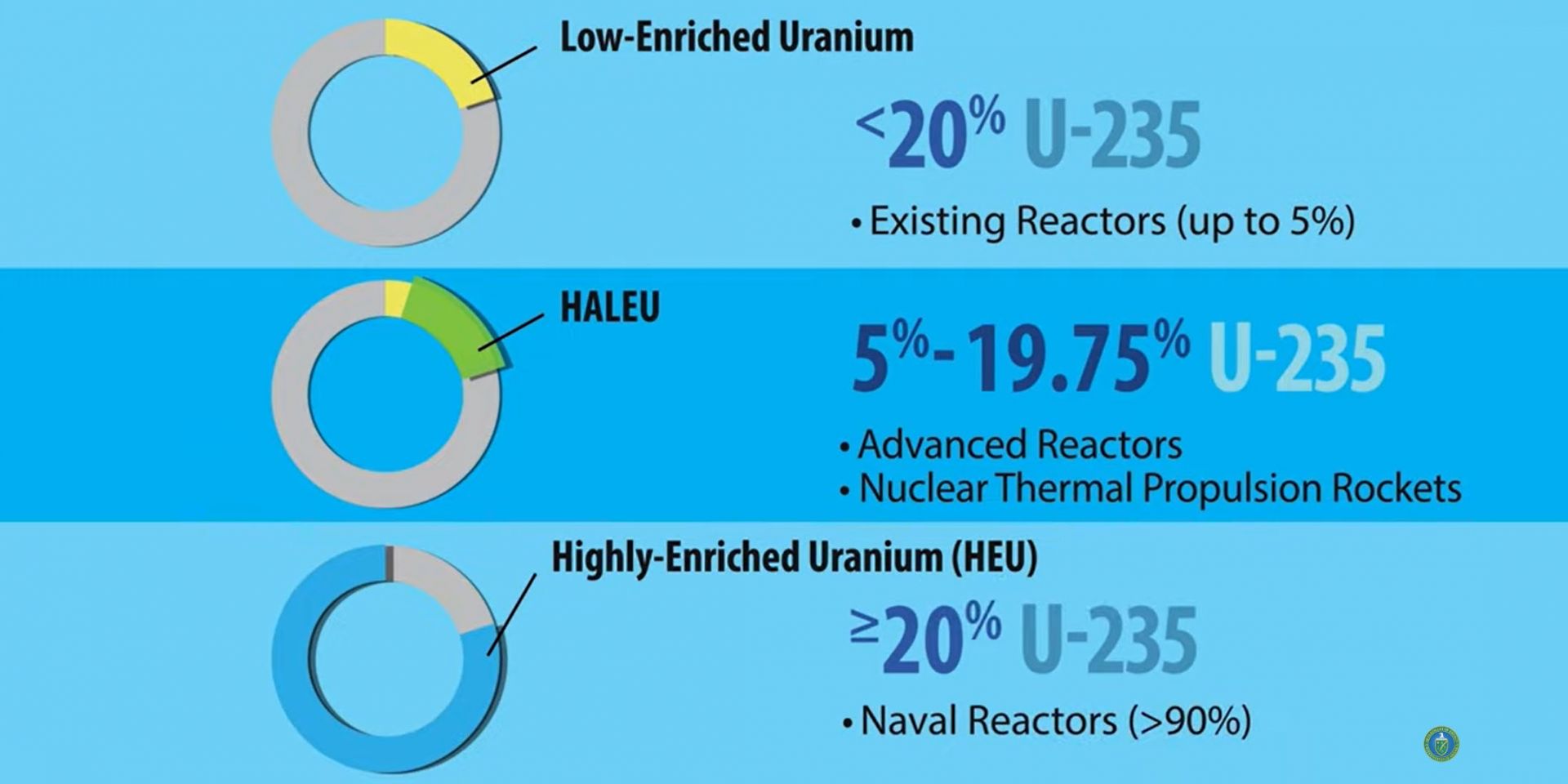

An image from the video “What is High-Assay Low-Enriched Uranium (HALEU)?” released by the DOE in April 2020. (Source: DOE)

Another piece of the plan for meeting the urgent need for high-assay low-enriched uranium (HALEU) to fuel advanced reactor deployments fell into place when the Department of Energy held an Industry Day on October 14. Attendees were asked how soon they could deliver 25 metric tons per year of HALEU enriched in the United States from newly mined uranium. Offtake contracts for six or more years of HALEU production at that rate could be used to stock a DOE-owned HALEU bank to “support [HALEU] availability for civilian domestic research, development, demonstration, and commercial use.”

Government officials and representatives of X-energy and its TRISO-X subsidiary at the October 13 groundbreaking. (Photo: X-energy)

Leaders of X-energy and its TRISO-X subsidiary gathered on October 13 to break ground at the site of what X-energy bills as “North America’s first commercial-scale advanced nuclear fuel facility” in Oak Ridge, Tenn. X-energy expects the TRISO-X Fuel Fabrication Facility (TF3) to create more than 400 jobs and to be commissioned and operational by 2025.