Hanford’s Waste Treatment and Immobilization Plant, also known as the Vit Plant. (Photo: Bechtel National)

BWX Technologies announced that the Department of Energy has approved Hanford Tank Waste Operations & Closure (H2C) to begin work under a contract valued at up to $45 billion to clean up tank waste at the Hanford Site near Richland, Wash. H2C is a limited liability company made up of BWXT Technical Services Group, Amentum Environment and Energy, and Fluor Federal Services.

The Nuclear Fuel Services facility in Erwin, Tenn. (Photo: BWXT)

BWX Technologies subsidiary Nuclear Fuel Services Inc. suspended operations last Friday at a Tennessee facility to assess conditions following Hurricane Helene. A company spokesperson said the site remained "in safe and secure condition."

Jeff Waksman (left), Project Pele program manager for DOD-SCO, and John Wagner, INL director, at the planned testing site. (Photo: DOD)

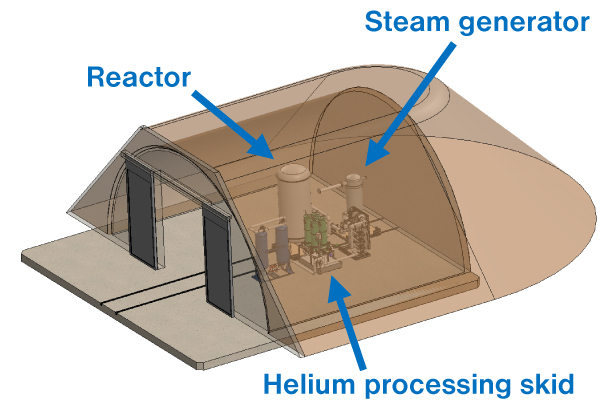

The Department of Defense announced September 24 that it has broken ground on the site at Idaho National Laboratory’s Critical Infrastructure Test Range Complex (CITRC) where Project Pele, a transportable 1–5 MWe microreactor, will be tested. The DOD’s Strategic Capabilities Office (SCO) is in charge, on a mission to prove that a mobile microreactor can help meet the DOD’s increasing demand for resilient carbon-free energy for mission-critical operations in remote and austere environments.

Concept art of BWXT’s BANR microreactor. (Source: BWXT)

BWX Technologies Inc. received the second phase of a contract with the Wyoming Energy Authority to assess the viability of deploying small-scale nuclear reactors in the state.

The company’s subsidiary, BWXT Advanced Technologies LLC, has been executing the agreement, working with the state of Wyoming to define the requirements for nuclear applications and to study the engineering work needed to support the state’s future power needs. BWXT identified areas where Wyoming’s supply chain could support nuclear reactor component manufacturing.

SRMC operators demonstrate procedure compliance during a job at the Savannah River Site’s Saltstone Production Facility. SRMC recently won national awards for demonstrating a commitment to working safely. (Photo: SRMC)

Department of Energy cleanup contractor Savannah River Mission Completion (SRMC) has garnered national recognition for its commitment to safety, recently receiving three awards from the National Safety Council: the Occupational Excellence Award, the Perfect Record Award, and the Superior Safety Performance Award.

Investment banking on higher demand for SMR and large nuclear reactors

BWX Technologies announced today plans to expand and add advanced manufacturing equipment to its manufacturing plant in Cambridge, Ontario, Canada.

A $36.3 million USD ($50M CAD) expansion will increase the plant’s size by 25 percent—to 280,000 square feet—and another $21.7 million USD ($30M CAD) will be spent on new equipment to increase and accelerate its output of large nuclear components. The investment will increase capacity and create more than 200 long-term jobs for skilled workers, engineers, and support staff, according to the company.

Hanford’s Waste Treatment and Immobilization Plant, also known as the Vit Plant. (Photo: Bechtel National)

The Department of Energy’s Office of Environmental Management once again awarded a 10-year, $45 billion contract to Hanford Tank Waste Operations and Closure (H2C) of Lynchburg, Va., for the cleanup of tank waste at the Hanford Site.

Argonne director Paul Kearns delivers the plenary lecture on the first day of the 2023 Atoms for Humanity symposium. (Photo: Purdue NE/CHE)

The roles of nuclear energy as a clean energy source and in space exploration were highlighted at the recent Atoms for Humanity symposium, held October 25–26, 2023. The symposium, which was organized by Purdue’s Center for Intelligent Energy Systems (CiENS) and hosted by the university’s School of Nuclear Engineering, was held on the West Lafayette, Ind., campus in Eliza Fowler Hall.

December 15, 2023, 4:56PMNuclear NewsDonna Kemp Spangler and Joel Hiller BWXT’s microreactor components would be designed to be transported directly from the factory to the deployment site. (Image: BWXT)

“The tools of the academic designer are a piece of paper and a pencil with an eraser. If a mistake is made, it can always be erased and changed. If the practical-reactor designer errs, he wears the mistake around his neck; it cannot be erased. Everyone sees it.”

Many in the nuclear community are familiar with this sentiment from Admiral Rickover. A generation of stagnation in the industry has underscored the truth of his words. But as economies around the world put a price on carbon emissions, there’s a renewed sense of urgency to deploy clean energy technologies. This shifts the global balance of economic competitiveness, and it’s clear that the best path forward for nuclear requires combining the agility of private innovators with the technology and capabilities of national laboratories.

Conceptual art of the Crowley-designed ship with a BWXT microreactor onboard. (Image: BWXT)

BWX Technologies is teaming with Crowley, a global shipping and energy supply chain company, under a memorandum of understanding to develop a ship with an onboard microreactor that could deliver power to users on shore via buoyed power cables. The concept, announced by both companies on September 20, is envisioned as a zero-carbon energy option for defense and disaster needs.