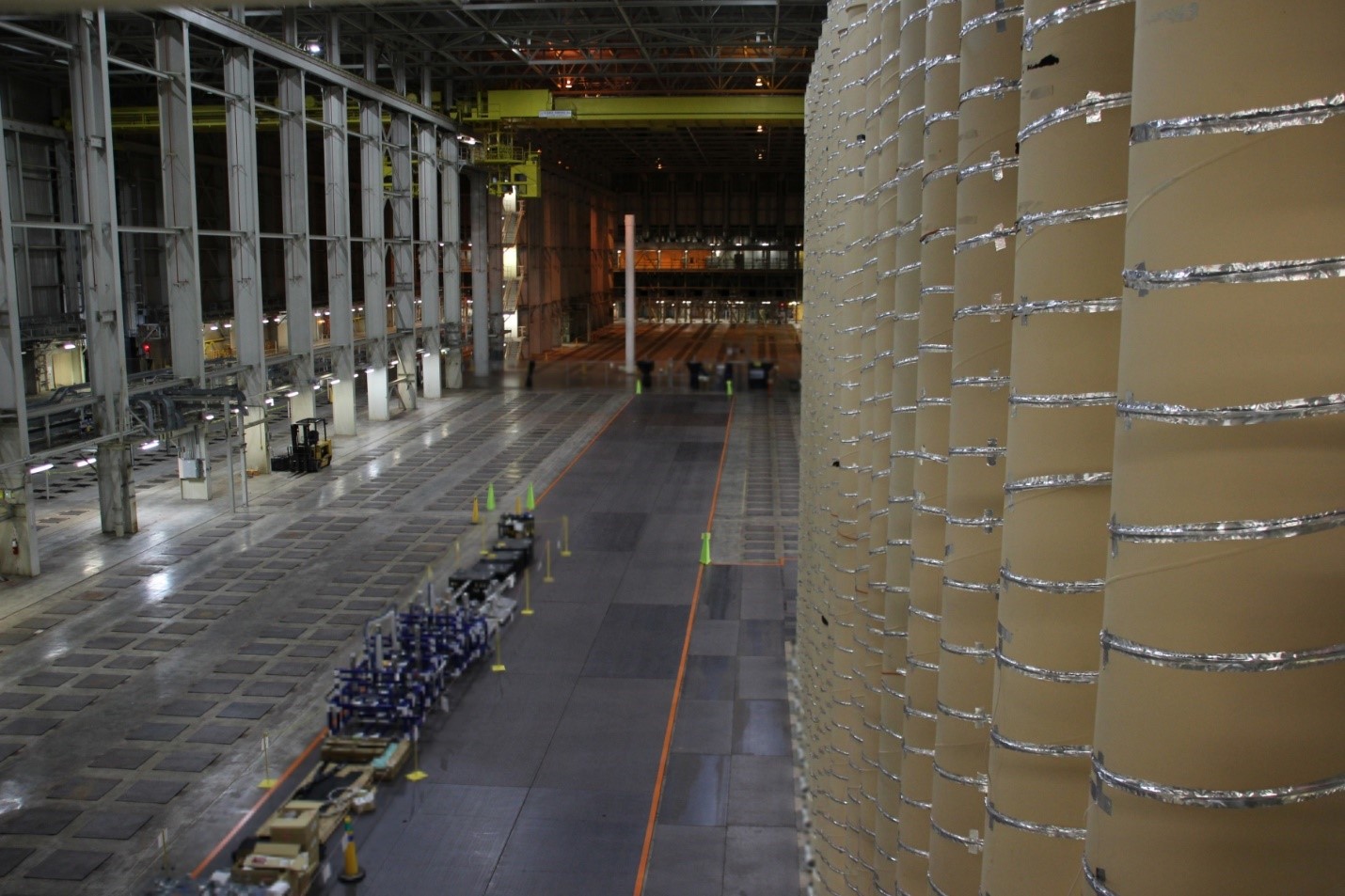

Uranium hexafluoride gas containers. (Photo: DOE)

The Department of Energy announced yesterday the six companies that it has selected to supply low-enriched uranium (LEU) from new domestic enrichment sources under future contracts for up to 10 years. The contract recipients are: Centrus Energy’s American Centrifuge Operating, General Matter, Global Laser Enrichment (GLE), Laser Isotope Separation Technologies (LIS Technologies), Orano Federal Services, and Urenco USA’s Louisiana Energy Services.

Centrus Energy staff posing in front of the American Centrifuge Plant. (Image: Centrus Energy)

Centrus Energy and the Department of Energy announced November 7 that Centrus has produced 20 kilograms of HALEU at the DOE-owned American Centrifuge Plant in Piketon, Ohio, satisfying Phase One of a DOE contract to stand up and operate 16 advanced centrifuges. Centrus will now move on to Phase Two of the contract, which requires a full year of HALEU production at a rate of 900 kilograms per year.

The 16-centrifuge HALEU demonstration cascade sits within a vast DOE-owned facility with room for more than 11,000 centrifuges. (Photo: Centrus)

American Centrifuge Operating (ACO), a subsidiary of Centrus Energy, has started enriching uranium hexafluoride gas to high-assay low-enriched uranium (HALEU) levels at the Department of Energy’s enrichment facility in Piketon, Ohio, the DOE announced October 11. The HALEU will be used to help fuel the initial cores of two demonstration reactors awarded under DOE’s Advanced Reactor Demonstration Program and will also support fuel qualification and the testing of other new advanced reactor designs.

Upper-level view of Centrus’s HALEU cascade. (Photo: Centrus Energy)

The Nuclear Regulatory Commission is requesting comments on the regulatory basis for a proposed rule for light water reactor fuel designs featuring high-assay low-enriched uranium (HALEU), including accident tolerant fuel (ATF) designs, and on draft guidance for the environmental evaluation of ATFs containing uranium enriched up to 8 percent U-235. Some of the HALEU feedstock for those LWR fuels and for advanced reactor fuels could be produced within the first Category II fuel facility licensed by the NRC—Centrus Energy’s American Centrifuge Plant in Piketon, Ohio. On September 21, the NRC approved the start of enrichment operations in the plant’s modest 16-machine HALEU demonstration cascade.

The site in Piketon, Ohio, where Oklo plans to deploy two microreactors under an agreement with Southern Ohio Diversification Initiative. (Photo: Oklo)

Oklo Inc. and Centrus Energy announced a new memorandum of understanding on August 28 to support the deployment of Oklo’s microreactor design, dubbed Aurora, near the Piketon, Ohio, site where Centrus plans to operate a high-assay, low-enriched uranium (HALEU) enrichment demonstration under contract to the Department of Energy by the end of the year.

View of the machine controls electronics of Centrus’s HALEU demonstration cascade. (Photo: Centrus)

TerraPower and Centrus Energy Corp. announced on July 17 that they have signed a memorandum of understanding to “significantly expand their collaboration aimed at establishing commercial-scale, domestic production capabilities for high-assay, low-enriched uranium (HALEU)” to supply fuel for TerraPower’s first Natrium reactor. Nearly three years ago, TerraPower first announced plans to work with Centrus to establish commercial-scale HALEU production facilities. The two companies signed a contract in 2021 for services to help expedite the commercialization of enrichment technology at Centrus’s Piketon, Ohio, facility.

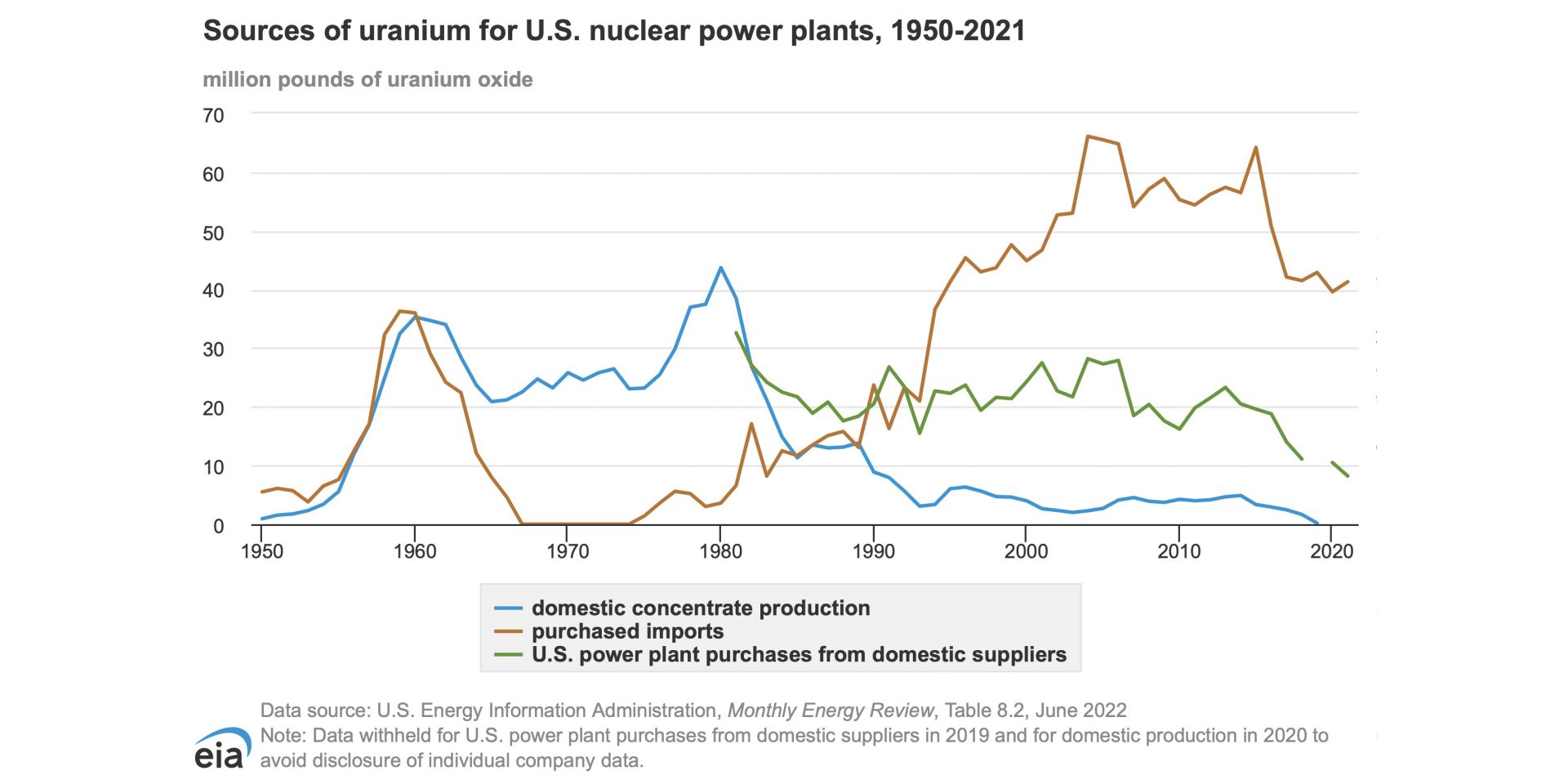

This chart from the EIA shows sources of uranium for U.S. nuclear power plants, 1950-2021. In 2020, according to the chart, 39.60 million pounds of uranium oxide was imported for the domestic nuclear power plant fleet. (Credit: Energy Information Agency)

The naturalist John Muir is widely quoted as saying, “When we try to pick out anything by itself, we find it hitched to everything else in the Universe.” While he was speaking of ecology, he might as well have been talking about nuclear fuel.

At the moment, by most accounts, nuclear fuel is in crisis for a lot of reasons that weave together like a Gordian knot. Today, despite decades of assertions from nuclear energy supporters that the supply of uranium is secure and will last much longer than fossil fuels, the West is in a blind alley. We find ourselves in conflict with Russia with ominous implications for uranium, for which Russia holds about a 14 percent share of the global market, and for two processes that prepare uranium for fabrication into reactor fuel: conversion (for which Russia has a 27 percent share) and enrichment (a 39 percent share).

A view of the completed demo cascade. (Photo: Centrus)

Centrus Energy announced February 9 that it has finished assembling a cascade of uranium enrichment centrifuges and most of the associated support systems ahead of its contracted demonstration of high-assay low-enriched uranium (HALEU) production by the end of 2023. When the 16-machine cascade begins operating inside the Piketon, Ohio, American Centrifuge Plant, which has room for 11,520 machines, it will be the first new U.S.-technology based enrichment plant to begin production in 70 years.

Participating in the forum were (from left) John Hopkins (NuScale Power), Renaud Crassous (EDF), Daniel Poneman (Centrus Energy), Adriana Cristina Serquis (CNEA), and Boris Schucht (Urenco).

The nuclear industry leaders assembled in Washington, D.C., last week to discuss small modular reactor supply chains agreed that lost generation capacity from the expected retirement of hundreds or thousands of coal power plants over the next decade—a cliff, in one panelist’s words—represents an opportunity that developers of SMRs and advanced reactors are competing to meet.

“I think in total 80 projects are ongoing,” said Boris Schucht, panel moderator and chief executive officer of Urenco Group, as he opened the forum. “Of course not all of them will win, and we will discuss today what is needed so that they can be successful.”