The Waste Isolation Pilot Plant in southeastern New Mexico.

Reston, Va.-based Tularosa Basin Range Services (TBRS), a single-purpose entity under the umbrella of Bechtel National, has been awarded the 10-year, $3 billion management and operating contract for the Waste Isolation Pilot Plant (WIPP) by the Department of Energy’s Office of Environmental Management (EM). Located near Carlsbad, N.M., WIPP is the DOE’s geologic repository for defense-generated transuranic waste.

The new contract replaces the current WIPP M&O contract held by Nuclear Waste Partnership, which expires on September 30. The contract with TBRS was announced on July 11.

The first steel columns, each weighing up to 28 tons, were placed for a cocoon over the former K East Reactor building at the Hanford Site. (Photo: DOE-EM)

The Department of Energy’s Office of Environmental Management (EM) said that construction is well underway on a protective enclosure, or cocoon, for the K East Reactor building at the Hanford Site near Richland, Wash.

EM reports that is has achieved one of its key construction priorities for 2022 by beginning construction of the enclosure, which is designed to protect the reactor building while the radioactivity in the deactivated reactor core decays over the next several decades, making it safer and easier to decommission.

A time-lapse video showing the construction of the cocoon’s massive 120-foot steel frame can be seen here.

A CAST Specialty Transportation truck loaded with TRUPACT-II shipping containers at WIPP. (Photo: DOE)

The Department of Energy’s Office of Environmental Management (EM) has awarded CAST Specialty Transportation a contract to provide transportation services for the Waste Isolation Pilot Plant, the DOE’s repository for defense-generated transuranic (TRU) waste near Carlsbad, N.M.

SRNS environmental engineers Bryce Garner (left) and Adam Willey (center) ask questions of lead operator Daniel Ferrell (right), from field services contractor Cascade Environmental, as he describes how equipment injects oil and iron into the Savannah River Site’s groundwater. (Photo: DOE)

In this week’s “EM Update,” the Department of Energy’s Office of Environmental Management (EM) reports that its contractor Savannah River Nuclear Solutions (SRNS) has successfully reduced degreasing solvents in the aquifer beneath the Savannah River Site in South Carolina using a technology that injects a form of iron and oil into groundwater.

“The oil attracts the Cold War[–era] cleaning solvents while the iron degrades and neutralizes the contamination,” said Shannan Lucero, SRNS manager for area closure projects.

Demolition crews remove some of the auxiliary structures surrounding the main building of the Criticality Experiment Laboratory on the Oak Ridge Reservation. (Photo: DOE)

A contractor for the Department of Energy’s Office of Environmental Management (EM) started tearing down a 1940s-era facility in May at the Y-12 National Security Complex in Oak Ridge, Tenn. Demolition of the former Criticality Experiment Laboratory, also known as Building 9213, is the latest project by EM to address a large inventory of high-risk excess contaminated facilities at the Oak Ridge Reservation.

Dae Chung, associate principal deputy assistant secretary for corporate services (second from left) and other EM officials recently toured the Paducah Site. Also pictured (from left) are Jennifer Woodard, acting senior advisor to Chung; Jolie Fleming, technical services director for Four Rivers Nuclear Partnership; and Lisa Phillips, physical scientist. In this photo, they discuss the new criticality accident alarm system in the C-333 process building at Paducah. The building is being deactivated to prepare for future demolition. (Photo: DOE)

Officials from the Department of Energy’s Office of Environmental Management recently got a firsthand look at cleanup progress being made at the Paducah Site in western Kentucky. The site is owned by the DOE, which is overseeing environmental cleanup activities there, including environmental remediation, waste management, depleted uranium conversion, and decontamination and decommissioning.

The visit by Dae Chung, associate principal deputy assistant secretary for corporate services, and other EM officials included stops at the C-400 cleaning building remediation project, the new Large Item Neutron Assay System (LINAS), and the C-333 process building deactivation.

Savannah River National Laboratory recently oversaw a demonstration of a new radiological inspection technology called iGART, a ground-based robot that conducts radiological and nuclear inspections. The DOE’s Office of Environmental Management used the demonstration at the Savannah River Site to determine if there is an application value for iGART at SRS or other EM sites. (Photos: DOE)

The Department of Energy’s Office of Environmental Management is looking to continue developing technology to aid in site cleanup activities if its fiscal year 2023 budget request is approved. The $7.64 billion budget request includes about $25 million for EM’s Technology Development Office.

Workers construct a new ventilation system's filter building last year at WIPP. (Photo: DOE)

Without a plan for addressing issues in completing construction projects at the Waste Isolation Pilot Plant in New Mexico, the Department of Energy cannot ensure that further cost increases and schedule delays will not continue, according to a report by the Government Accountability Office. In particular, the GAO said, the DOE has not developed a corrective action plan to address root causes identified for the rising cost and the delay in building a new ventilation system at the transuranic waste repository.

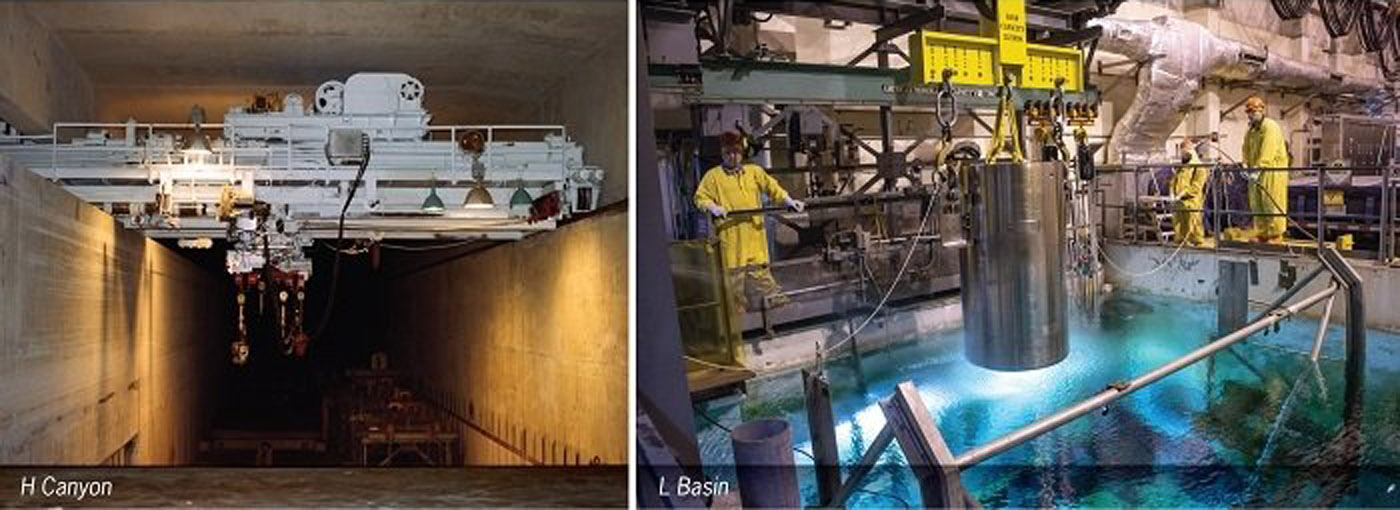

Spent nuclear fuel handlers move the last ATR fuel to an awaiting cask in the CPP-666 basin. (Photo: DOE)

The last spent nuclear fuel elements from Idaho National Laboratory’s Advanced Test Reactor (ATR) have been retrieved from a water-filled storage basin and transferred to a nearby dry-storage facility in accordance with a 1995 agreement with the State of Idaho, the Department of Energy’s Office of Environmental Management (EM) announced this week.

A screen shot of a YouTube video of the DOE’s U-233 Initial Processing Campaign at Oak Ridge National Laboratory.

Isotek, the Department of Energy contractor responsible for overseeing the inventory of uranium-233 at Oak Ridge National Laboratory and preparing it for removal from the site, said it plans to resume preparations for processing high-dose U-233 in March. The company was forced to suspend its operational readiness review of the Initial Processing Campaign at Oak Ridge in January due to issues related to COVID-19, as well as difficulties operating in colder temperatures.

The IWTU liquid nitrogen storage system at the DOE’s Idaho National Laboratory Site. (Photo: DOE)

The Department of Energy’s Office of Environmental Management (EM) stated on February 22 that its Idaho National Laboratory Site contractor is operating the final test run of the Integrated Waste Treatment Unit (IWTU), running waste simulant through the facility to ensure the plant’s performance and personnel proficiency for upcoming radiological operations.

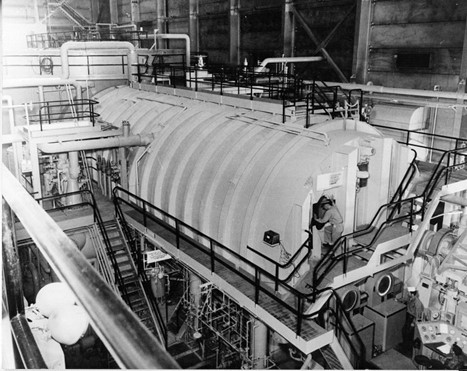

The interior of the Submarine 1st Generation Westinghouse prototype, located at the Naval Reactors Facility on the INL site, circa mid-1950s. (Photo: DOE)

The Department of Energy’s Office of Environmental Management (EM) announced on February 10 that it is set to deactivate and demolish the prototype for the reactor used for the USS Nautilus, the world’s first operational nuclear-powered submarine and the first submarine to complete a submerged transit of the North Pole.

WRPS operations engineer Steven Porter, left, and nuclear chemical operator Brent Walker monitor the TSCR System in the control room as the system is put in operations mode. (Photo: DOE)

The Department of Energy announced on Wednesday that the first large-scale treatment of radioactive and chemical waste from underground tanks at the Hanford Site near Richland, Wash., has begun with the start of operations of the Tank-Side Cesium Removal (TSCR) System.

The newly operational TSCR System removes radioactive cesium and solids from the tank waste. The treated waste will be fed directly to the nearby Waste Treatment and Immobilization Plant (WTP) for vitrification when the plant comes on line next year.

Workers recently installed manipulator equipment at a full-scale mock-up of areas of the Hanford Site’s Waste Encapsulation and Storage Facility. (Photo: DOE)

The Department of Energy’s Office of Environmental Management (EM) announced this week that preparations are well underway for the transfer of nearly 2,000 highly radioactive cesium and strontium capsules from the Waste Encapsulation and Storage Facility (WESF) to interim dry storage at the Hanford Site near Richland, Wash.

Employees wearing supplied-air equipment work through clues in an “escape room” during respiratory protection training at Hanford’s Volpentest HAMMER Federal Training Center. (Photo: DOE)

A new respiratory protection course at the Department of Energy’s Hanford Site near Richland, Wash., features an “escape room” in which employees wear supplied-air equipment while they answer questions, discover clues, and solve puzzles in a simulated work environment.

Crews take down the Load-In Facility at the West Valley Demonstration Project. The demolition is scheduled for completion early next year. (Photo: DOE)

The Department of Energy’s Office of Environmental Management (EM) is set to complete the 69th building demolition at the West Valley Demonstration Project early next year, when crews finish knocking down the last structure standing that supported operations at the former Main Plant Process Building.

Electrician Ralph Bisla conducts tests of the finishing line inside Hanford’s WTP Low-Activity Waste Facility. (Photo: DOE)

Having completed all startup testing of components and systems, the Waste Treatment and Immobilization Plant (WTP) at the Hanford Site near Richland, Wash., has moved to the commissioning phase, the Department of Energy’s Office of Environmental Management (EM) announced last week. During the commissioning phase, the final steps will be taken to prepare for the vitrification of radioactive and chemical waste as part of Hanford’s Direct-Feed Low-Activity Waste (DFLAW) program.

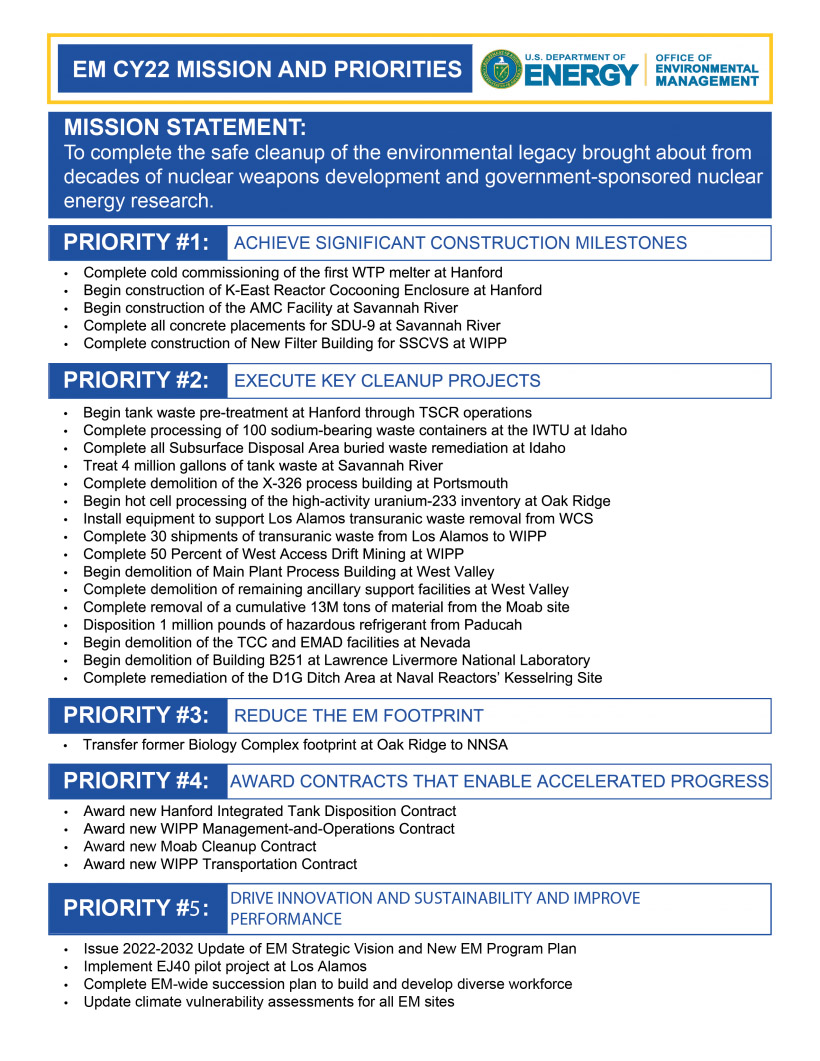

The Department of Energy’s Office of Environmental Management (EM) has established its key priorities for calendar year 2022, covering planned cleanup, project construction, acquisition, and other important accomplishments to advance the office’s environmental and risk-reduction mission. EM is responsible for handling the nation’s Cold War environmental legacy resulting from five decades of nuclear weapons production and government-sponsored nuclear energy research.

The Department of Energy’s Office of Environmental Management (EM) has established its key priorities for calendar year 2022, covering planned cleanup, project construction, acquisition, and other important accomplishments to advance the office’s environmental and risk-reduction mission. EM is responsible for handling the nation’s Cold War environmental legacy resulting from five decades of nuclear weapons production and government-sponsored nuclear energy research.