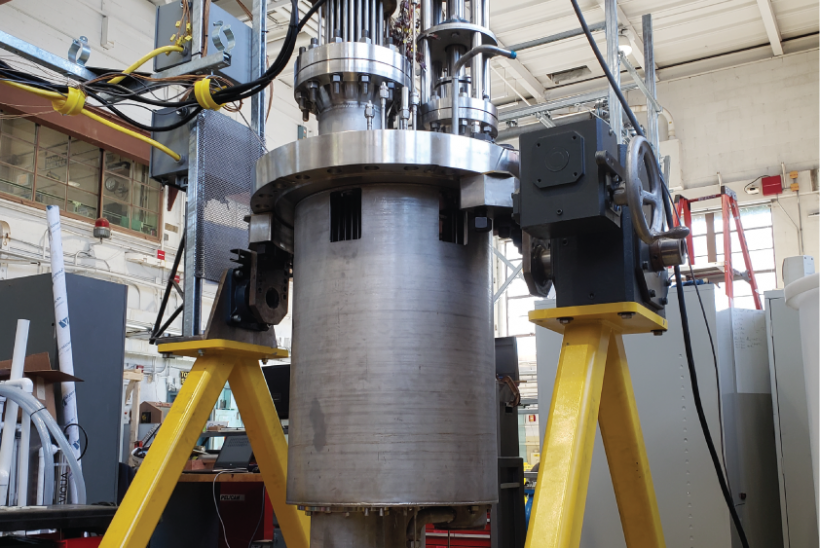

The primary system of THETA at Argonne’s Mechanisms Engineering Test Loop Facility, where Oklo is conducting sodium thermal-hydraulic testing with support from a GAIN award announced in 2021. (Image: Argonne National Laboratory)

The Department of Energy and the Gateway for Accelerated Innovation in Nuclear (GAIN) on March 19 announced the second round of fiscal year 2024 voucher awards to three companies: Element Factory, Kanata America, and Oklo.

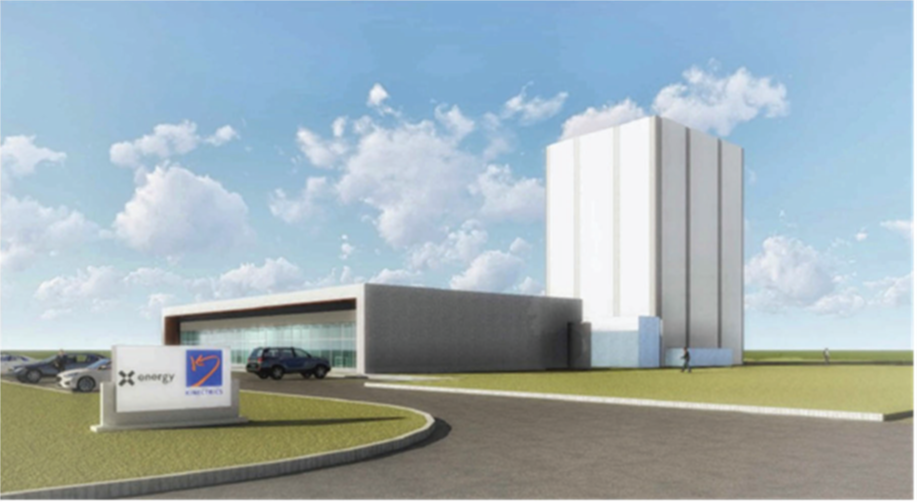

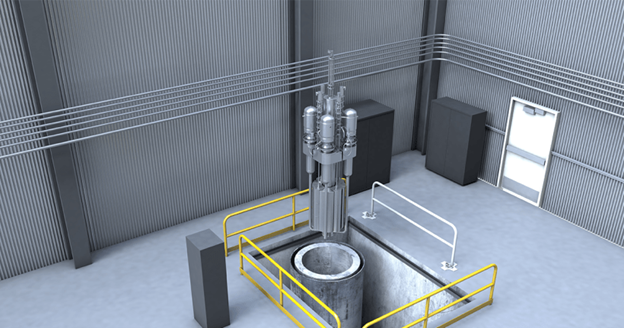

Concept art of the planned X-energy helium test facility. (Image: DOE OCED)

The Department of Energy’s Office of Clean Energy Demonstrations issued a final environmental assessment (EA) and finding of no significant impact in February for a cost-shared X-energy project to construct and operate a helium test facility (HTF) in Oak Ridge, Tenn. According to the EA, construction would begin in early 2024 and take X-energy and its contracted partner, Kinectrics, about one year to complete. the facility would then operate for six years, with the possibility of extensions for up to an additional 20 years, to test equipment for a demonstration of X-energy’s high-temperature, gas-cooled reactor technology and also to “serve the reactor community at large as the technology continues to develop and is adopted around the world.”

The Washington State University Tri-Cities campus. (Photo: WSU)

A new engineering scholarship at Washington State University (WSU) Tri-Cities has been established by Longenecker & Associates for students interested in careers that support Department of Energy missions.

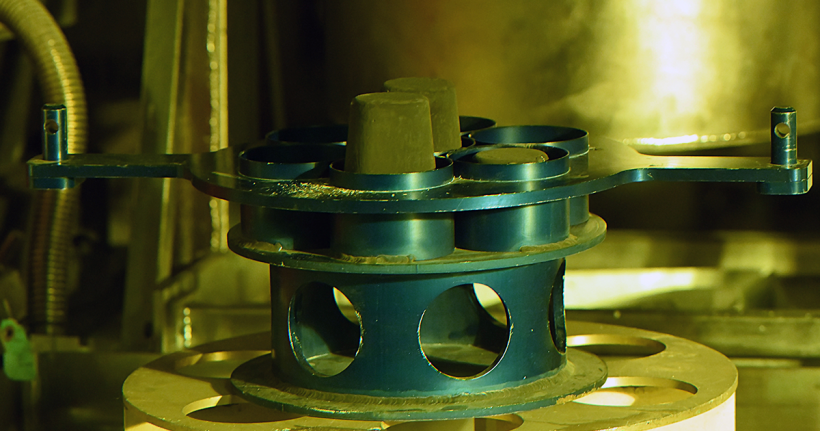

HALEU reguli fabricated from downblended high-enriched uranium recovered from legacy EBR-II fuel at Idaho National Laboratory. (Image: DOE)

The Department of Energy yesterday announced a draft environmental impact statement (EIS) on HALEU Availability Program plans to purchase high-assay low-enriched uranium under 10-year contracts to seed the development of a sustainable commercial HALEU supply chain.

The DOE's Waste Isolation Pilot Plant. (Photo: DOE)

TVA's Bull Run fossil plant. (Photo: TVA)

Type One Energy Group announced plans on February 21 to relocate its headquarters from Madison, Wis., to the Tennessee Valley Authority’s (TVA) Bull Run fossil plant in Clinton, Tenn., where it will build a stellarator fusion prototype machine. According to the company, the construction of the stellarator—called Infinity One—could begin in 2025, if necessary environmental reviews, partnership agreements, permits, and operating licenses are all in hand.

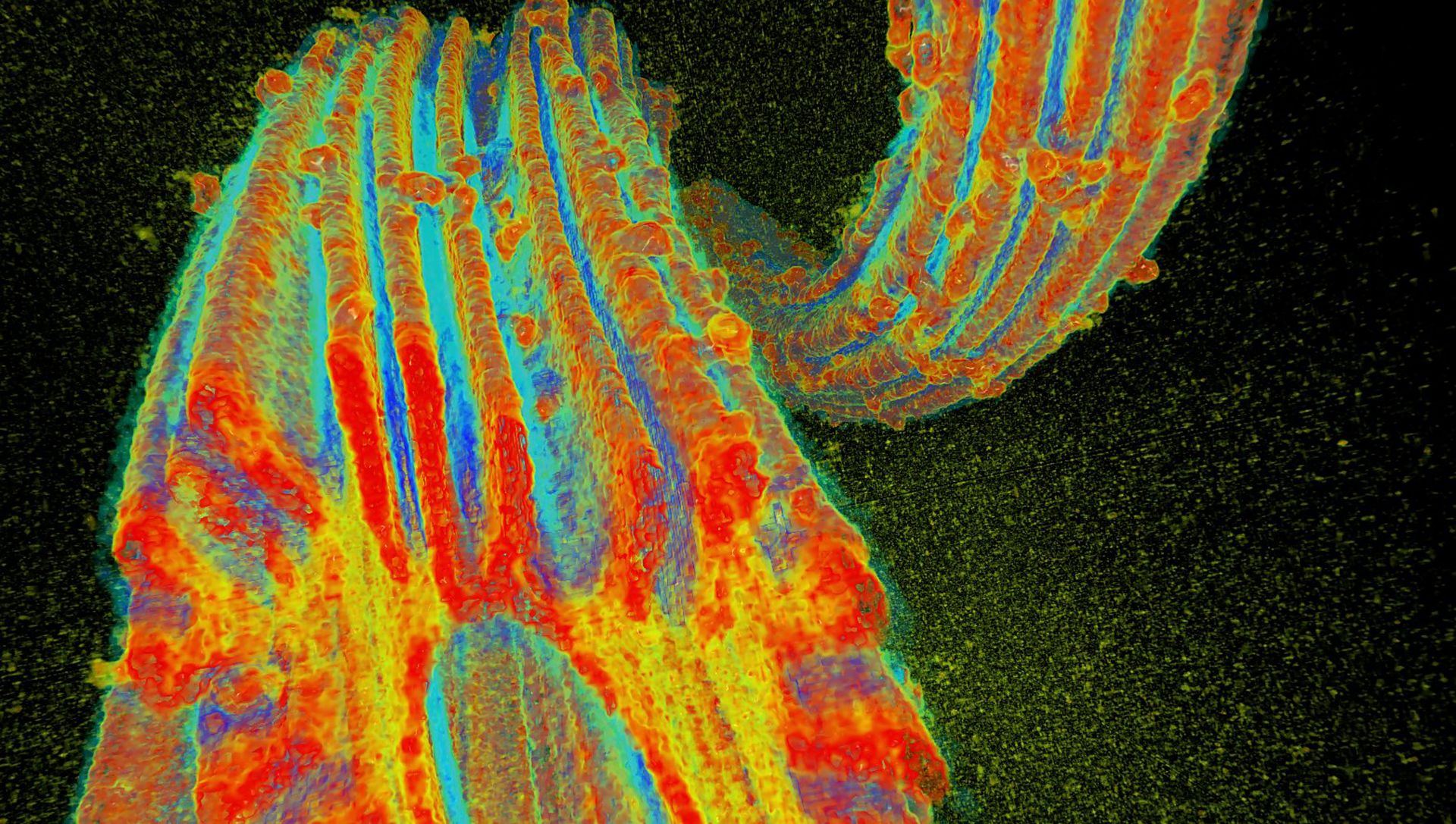

Researchers have been working frantically to develop an array of materials and fibers to economically extract uranium from seawater—and they have succeeded. PNNL scientists exposed this special uranium-sorbing fiber developed at ORNL to Pseudomonas fluorescens and used the Advanced Photon Source at Argonne National Laboratory to create a 3-D X-ray microtomograph to determine microstructure and the effects of interactions with organisms and seawater. (Image: PNNL)

America, Japan, and China are racing to be the first nation to make nuclear energy completely renewable. The hurdle is making it economical to extract uranium from seawater, because the amount of uranium in seawater is truly inexhaustible.

While America had been in the lead with technological breakthroughs from the Department of Energy’s Pacific Northwest and Oak Ridge National Laboratories, researchers at Northeast Normal University in China have sprung ahead. But these breakthroughs from both countries have brought the removal of uranium from seawater within economic reach. The only question is when will the source of uranium for our nuclear power plants change from mined ore to seawater extraction?

Aiken County Public School District students test out a mock glovebox during a tour of the Savannah River Site’s Waste Solidification Building. (Photo: SRNS)

Fifteen area high school students recently completed job shadow experiences with leaders, engineers, and education outreach personnel at the Department of Energy’s Savannah River Site in South Carolina, according to Savannah River Nuclear Solutions (SRNS).

Radioisotopes target cancer, improve imaging, and have myriad other medical uses

ORNL radioisotope manufacturing coordinator Jillene Sennon-Greene places a shipment vial of actinium-225 inside the dose calibrator to confirm its activity is within customer specifications. (Photo: Carlos Jones/ORNL, DOE)

On August 2, 1946, 1 millicurie of the isotope carbon-14 left Oak Ridge National Laboratory, bound for the Barnard Free Skin and Cancer Hospital in St. Louis, Mo.

That tiny amount of the radioisotope was purchased by the hospital for use in cancer studies. And it heralded a new peacetime mission for ORNL, built just a few years earlier for the production of plutonium from uranium for the Manhattan Project.

Concept art of the MARVEL microreactor (Image: INL)

The Department of Energy announced February 7 that fuel for the MARVEL microreactor, which Idaho National Laboratory plans to host inside the Transient Reactor Test (TREAT) facility, is now being fabricated by TRIGA International, with the first fuel delivery expected in spring 2025. MARVEL operation was expected “by the end of 2024” as recently as May 2023, but that timeline had shifted by October, when the DOE said MARVEL “is expected to be completed in early 2025.” Now, according to the DOE’s latest announcement, “Fuel loading for MARVEL is anticipated to occur in 2026, with the microreactor expected to be on line by 2027.”

Argonne director Paul Kearns delivers the plenary lecture on the first day of the 2023 Atoms for Humanity symposium. (Photo: Purdue NE/CHE)

The roles of nuclear energy as a clean energy source and in space exploration were highlighted at the recent Atoms for Humanity symposium, held October 25–26, 2023. The symposium, which was organized by Purdue’s Center for Intelligent Energy Systems (CiENS) and hosted by the university’s School of Nuclear Engineering, was held on the West Lafayette, Ind., campus in Eliza Fowler Hall.

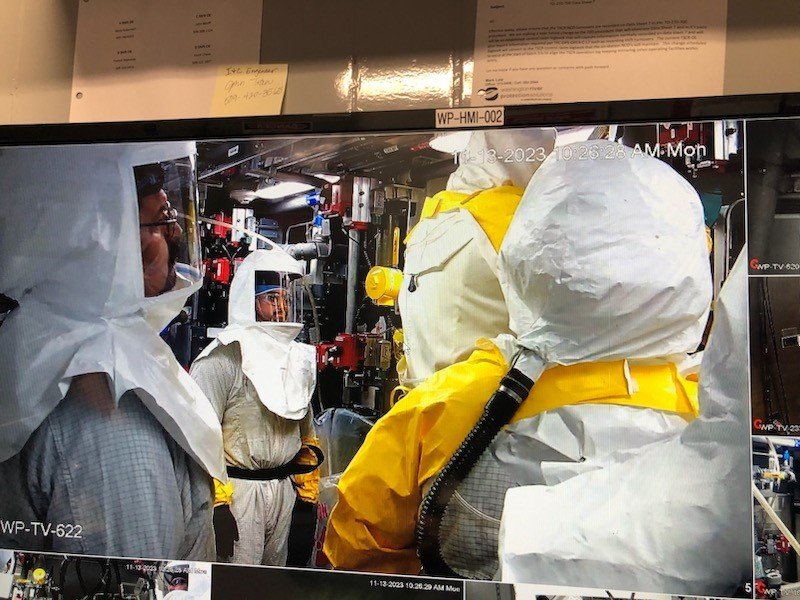

A monitor in the control room of the Hanford Site’s TSCR system shows workers performing maintenance inside the TSCR facility. (Photo: DOE)

The Department of Energy Office of Environmental Management’s Office of River Protection and contractor Washington River Protection Solutions have completed the first waste processing campaign through the Tank-Side Cesium Removal (TSCR) system at the Hanford Site.