DTC Operator Apprentice graduates include David Tolias, Scottie Tarver, Brandon Watkins, Johnaisha Patterson, Dustin Bates, Kyler McKie, Hudson Huckabee, Laura Burgess, Larry Tyler, Kevin Dickson, Matthew Darnall, John Bolin, Austin Harper, Jordan Floyd, and Mina Strickland. (Photo: DOE)

The Department of Energy’s Savannah River Site in South Carolina recently began onboarding 24 graduates from Denmark Technical College in Denmark, S.C., as part of SRS’s Production Operator Apprentice School.

Tennessee officials and lawmakers joined Orano representatives to announce Orano’s selection of Oak Ridge as its preferred site for a uranium enrichment facility. (Photo: tn.gov)

On September 4, Tennessee Gov. Bill Lee announced that Orano had selected Oak Ridge as its preferred site to build a “multibillion-dollar” uranium centrifuge enrichment facility. For Tennessee, the announcement underscores Oak Ridge’s draw for nuclear technology companies. For Orano and the nuclear power community, the announcement is another sign the nation is edging closer to adding front-end nuclear fuel cycle capacity.

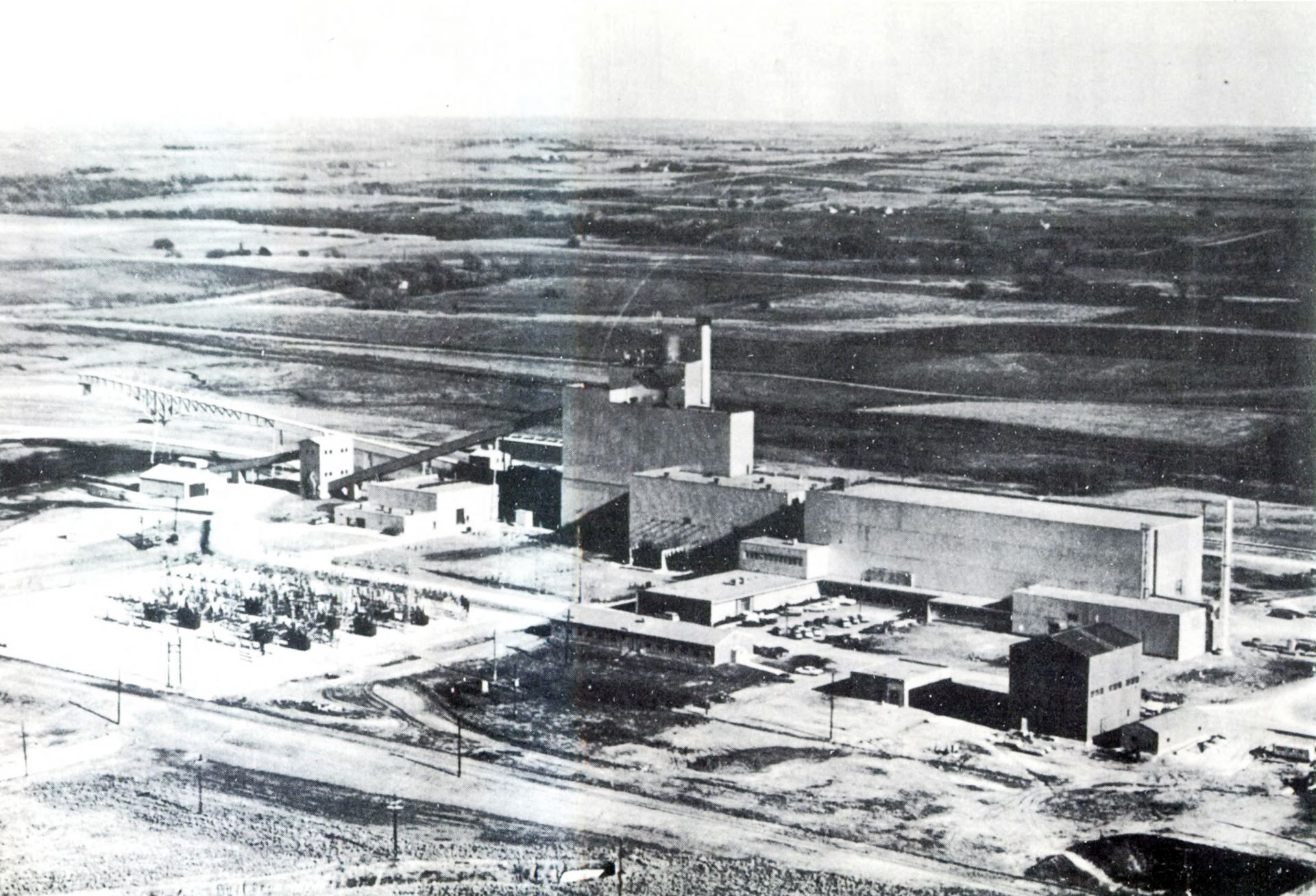

Aerial view of Hallam nuclear power plant (toward right) and Sheldon Power Station (toward left). (Photo: U.S. AEC/Wiki Commons)

The Hallam nuclear power plant in Nebraska, about 25 miles southwest of Lincoln, was a 75-MWe sodium-cooled, graphite-moderated reactor operated by Consumers Public Power District of Nebraska (CPPD). It was co-located with the Sheldon Power Station, a conventional coal-fired plant. The facility had a shared control room and featured a shared turbo generator that could accept steam from either heat source.

This series of photos shows the grouting of the K West Reactor spent fuel storage basin. Workers removed nearly 1 million gallons of contaminated water before filling the 16-foot-deep basin with about 6,500 cubic yards of grout—enough to fill two Olympic-size swimming pools. (Images: DOE)

Workers at the Department of Energy’s Hanford Site in Washington state recently finished filling the last large concrete basin at the K Reactor Area with cement-like grout. The basin stored reactor fuel rods from historic plutonium production in the 1950s.

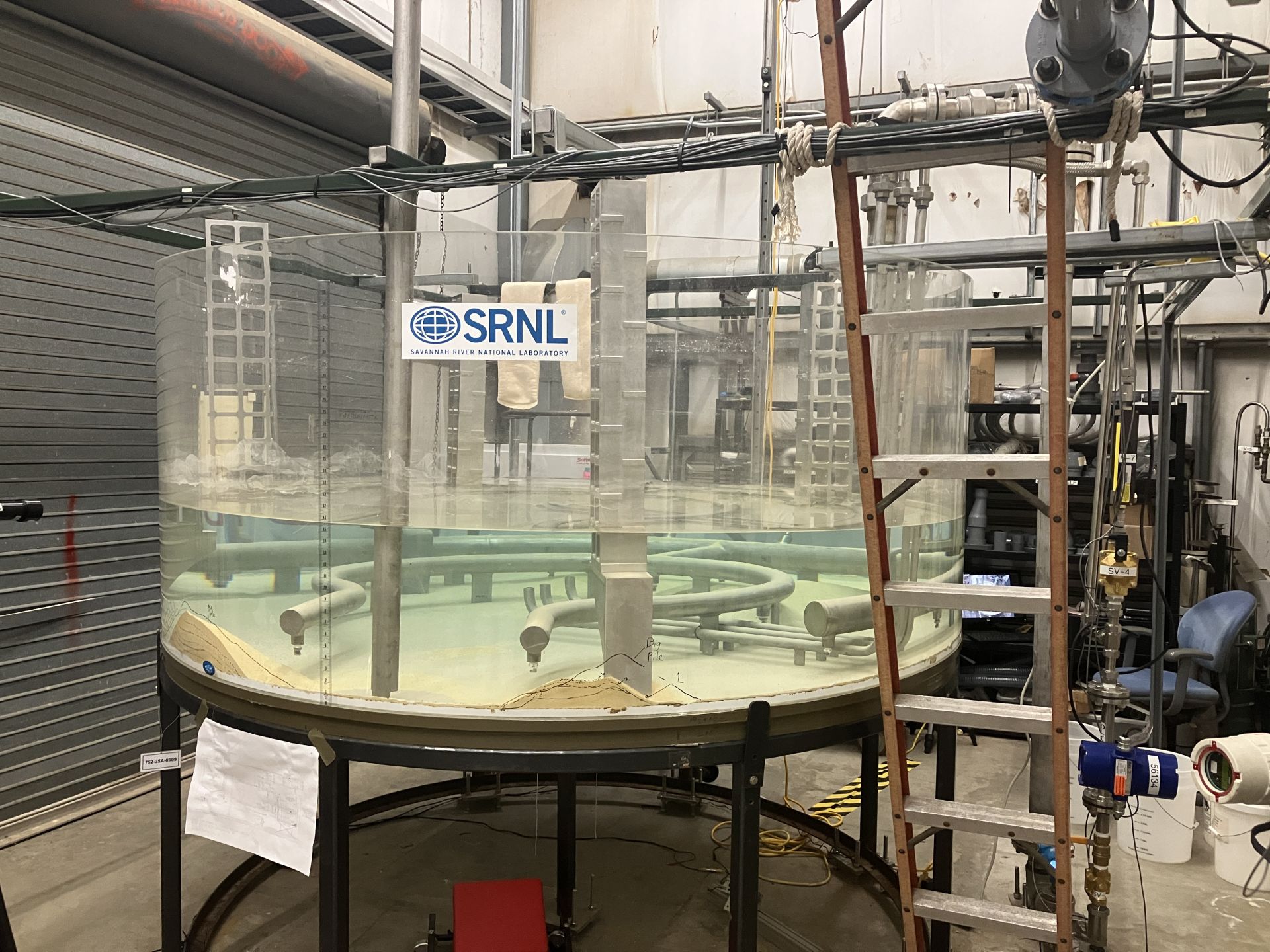

A mock-up model at SRNL was used to demonstrate a full-scale jet cleanout system to remove undissolved material from the H Canyon electrolytic dissolver. (Photo: DOE)

A collaboration between Savannah River Nuclear Solutions (SRNS) and Savannah River National Laboratory (SRNL) is making progress toward processing non-aluminum spent nuclear fuel (NASNF) as part of the site’s accelerated basin de-inventory mission. SRNL is the managing and operating contractor at the Department of Energy’s Savannah River Site in South Carolina.

The D Area Groundwater Treatability Study project team assesses artesian flow into injection well at the Savannah River Site. (Photo: SRNS)

Savannah River Nuclear Solutions (SRNS), the management and operations contractor for the Department of Energy’s Savannah River Site, announced that it has injected more than 100 million gallons of clean artesian well water to neutralize shallow groundwater contamination underneath 33 acres of a former coal storage yard and the associated runoff basin at the site in South Carolina. According to Ashley Shull, senior scientist for the project, “100 million gallons is nine times more water than [is] contained in the Georgia Aquarium in Atlanta.”

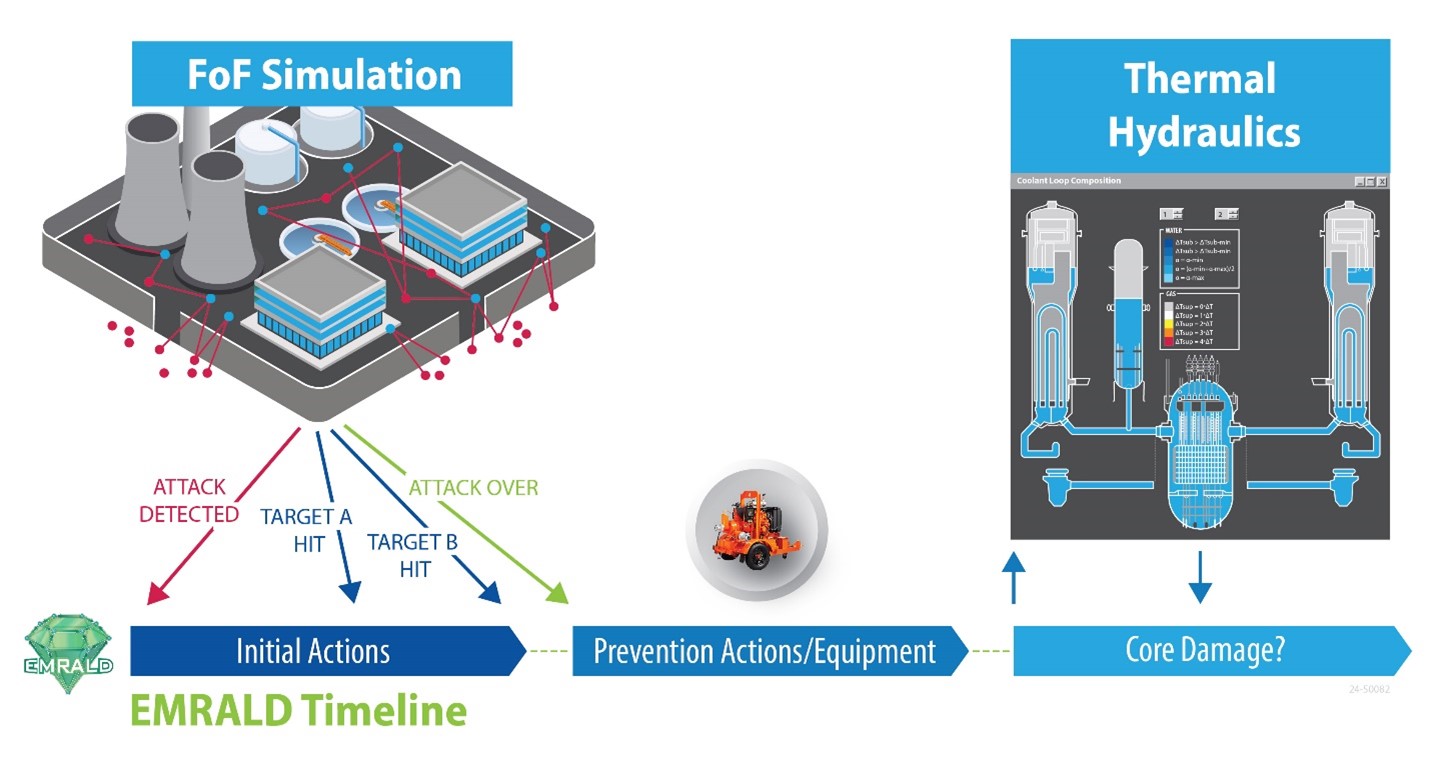

The MASS-DEF framework with prevention actions and timelines modeled in EMRALD software interacting with force-on-force (FoF) simulation and thermal hydraulics models. The risk-informed modeling in the MASS-DEF framework integrates physical security effectiveness analysis with safety measures, such as time to core damage. (Graphic: INL)

Today’s nuclear power plants are the nation’s largest source of carbon-free energy, but they come with high operating and maintenance costs.

Competition from other sources, especially natural gas, coupled with low electricity prices, has resulted in the closure of some plants in the last decade due to economic reasons.

One way to alleviate these economic pressures is to reduce the cost of operating nuclear power plants, including the costs associated with physical security.

Teams use a 20-ton overhead crane to move the lower reactor vessel of the Oak Ridge Research Reactor into a cask for eventual shipment and disposal. (Photo: DOE)

Matthew Jasica is a member of a small team conducting large-scale experimental testing of reactors and their components at the NSTF. (Photo: Argonne)

A facility at Argonne National Laboratory has been simulating nuclear reactor cooling systems under a wide range of conditions since the 1980s. Its latest task, described by Argonne in an August 13 news release, is testing the performance of passive safety systems for new reactor designs.

Designed as a half-scale model of a real reactor system, Argonne’s Natural Convection Shutdown Heat Removal Test Facility (NSTF) is used for large-scale experimental testing of the performance of passive safety systems, which are designed to remove decay heat using natural forces including gravity and heat convection. Those tests yield benchmarking data qualified to the level of National Quality Assurance-1 (NQA-1) that is shared with vendors and regulators to validate computational models and guide licensing of new reactors and components.

Westinghouse ADOPT fuel pellets. (Photo: Westinghouse)

Westinghouse Electric Company announced Aug. 8 that it has completed the first pressing of ADOPT nuclear fuel pellets at the company’s Springfields Fuel Manufacturing Facility in the United Kingdom. The pellets, which can contain up to 8 percent uranium-235 by weight, are destined for irradiation testing in Southern Nuclear’s Vogtle-2 pressurized water reactor.

A glass test cell that was fabricated to visualize noble gas behavior in a stagnant molten salt column. (Photo: ORNL)

Transparency is one advantage of certain molten salts that could serve as both a coolant and fuel carrier in an advanced reactor. For scientists studying molten salt chemistry and behavior at the laboratory scale, it helps if the test vessel is transparent too. Now, Oak Ridge National Laboratory has created a custom glass test cell with a 1-liter capacity to observe how gases move within a column of molten salt, the Department of Energy announced August 5.

The Defense Nuclear Facilities Safety Board, which provides safety oversight of Department of Energy sites, is holding a

The Defense Nuclear Facilities Safety Board, which provides safety oversight of Department of Energy sites, is holding a