Using GeoMelt ICV technology to treat and immobilize problematic low-level wastes at INL and WCS.

A sample of GeoMelt glass. (Photos: Veolia)

When it comes to managing nuclear waste, technology is transforming the way some of the most problematic waste is handled. The idea to transform nuclear waste into glass was developed back in the 1970s as a way to lock away the waste’s radioactive elements and prevent them from escaping. For more than 40 years, vitrification has been used for the immobilization of high-level radioactive waste in many countries around the world, including the United States.

Concrete blocks are loaded onto a metal base and transporter during tests on a gantry crane system that will lift replacement melters for Hanford’s WTP. (Photo: DOE)

The Department of Energy has announced that tank operations contractor Washington River Protection Solutions (WRPS) and subcontractor Atkins are making progress at the Hanford Site in Washington state in their preparations to provide replacement melters to treat radioactive and chemical tank waste for the site’s Direct-Feed Low-Activity Waste program.

Two empty waste tanks weighing more than five tons each were transported from outside the Hanford Site’s Effluent Treatment Facility to an on-site landfill. (Photo: DOE)

Two large tanks near the Effluent Treatment Facility (ETF) at the Department of Energy’s Hanford Site in Washington state were removed recently to make way for future wastewater treatment activities at the ETF.

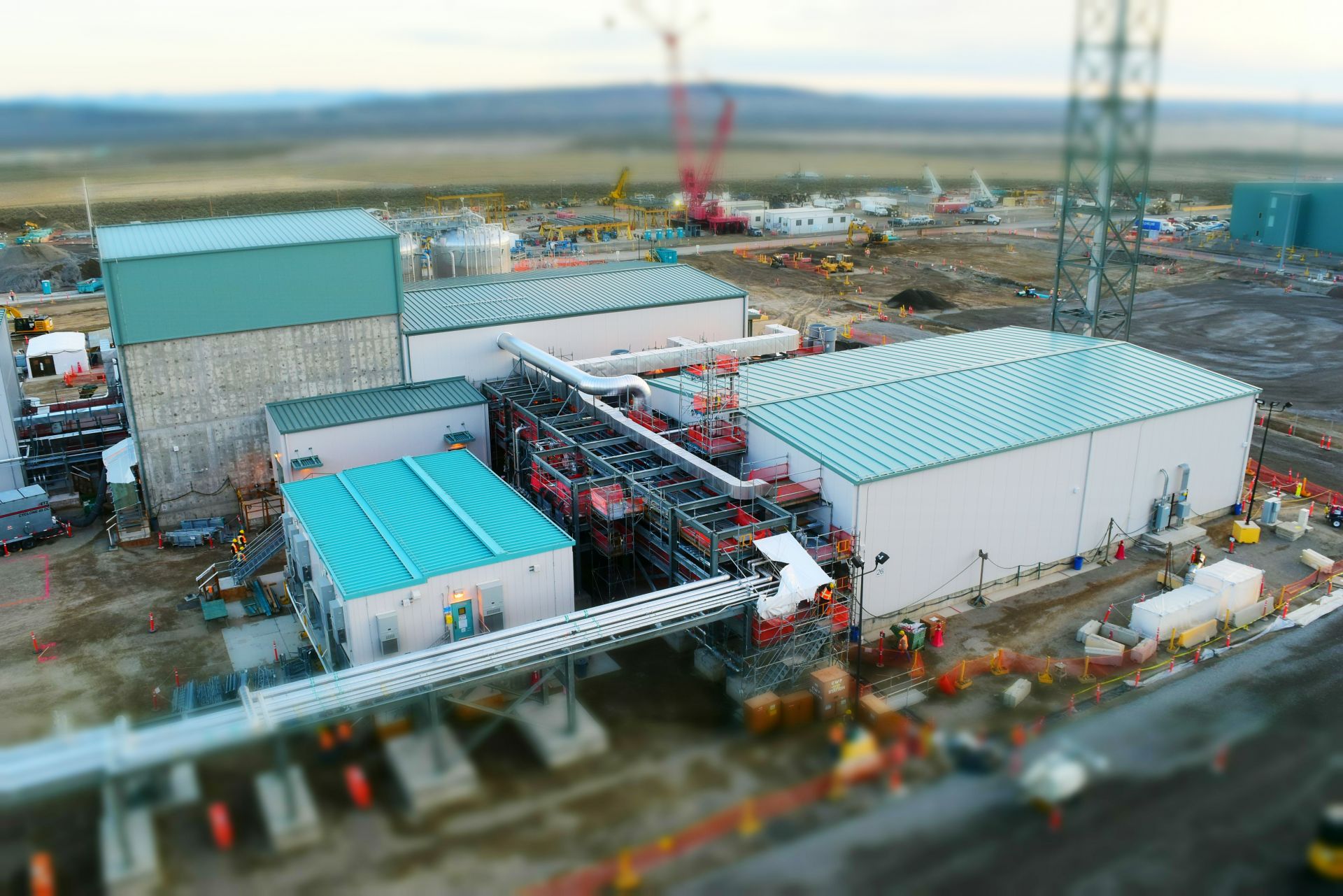

Hanford’s Waste Treatment and Immobilization Plant. (Photo: DOE)

The Department of Energy is asking for feedback on a new report analyzing potential options for preparing high-level radioactive waste for vitrification at the department’s Hanford Site near Richland, Wash. Vitrification is the process of treating radioactive waste by immobilizing it in glass.

The report, Waste Treatment and Immobilization Plant High-Level Waste Treatment: Analysis of Alternatives, was commissioned in response to a 2018 determination by the U.S. Army Corps of Engineers that it was unlikely the DOE would meet its mandated deadlines for treating Hanford’s tank waste.

An aerial view of Hanford’s Plutonium Uranium Extraction plant, showing the main facility (at center), the 211-A chemical storage area, and (in foreground) the 203-A acid storage area. (Photo: DOE)

Work crews at the Department of Energy’s Hanford Site in Washington state are performing risk-reduction activities at the Plutonium Uranium Extraction (PUREX) plant to prepare it for eventual disposition.

“It will be a yearslong effort to get this large facility ready for disposition, and I’m encouraged by the progress to safely and efficiently advance this work,” said Andy Wiborg, the DOE’s Projects and Facilities Division team lead for Hanford’s Central Plateau cleanup project.

A tanker holding 6200 gallons of leachate unloads at a backup load-in station at the Hanford Site’s ETF. (Photo: DOE)

Construction of a backup load-in station has been completed at the Hanford Site’s Effluent Treatment Facility (ETF) in Washington state.

“We broke ground on the backup facility about a year ago,” said Rob Wood, project manager for Washington River Protection Solutions, the Department of Energy’s tank operations contractor at the site. “I am proud of the team for completing this portion of the load-in expansion project and doing it safely. In phase two, expansion of the main load-in station will prepare us for 24/7 operations on the Hanford Site.”

Watch a time-lapse video of the backup load-in station construction here.

DOE contractor CPCCo recently completed construction of a protective cocoon over the former K East Reactor building at Hanford. (Photo: DOE)

The Department of Energy’s Office of Environmental Management (EM) announced that construction of Hanford’s K East Reactor cocoon has been completed ahead of schedule and under budget. Cocooning of K East—enclosing it in a protective steel structure while the reactor’s radioactivity naturally decays—was one of EM’s key construction priorities for 2022.

Workers install one of 18 startup heaters into Melter 1 of Hanford’s Low-Activity Waste Facility. (Photo: Bechtel National)

Heating of the first waste vitrification melter at the Department of Energy’s Hanford Site was paused after operators identified an “abnormal condition with the startup heater power supplies,” the DOE’s Office of River Protection (ORP) said. Heat-up of the 300-ton melter, which will be used to vitrify Hanford’s low-level radioactive tank waste, was initiated on October 8.

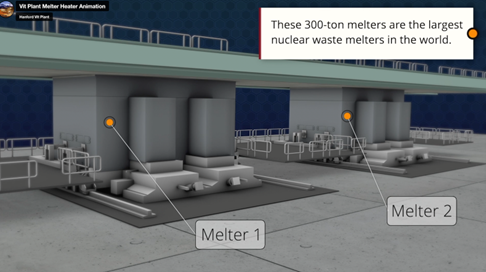

A screenshot from a 3D animation showing the heat-up of Hanford’s melters. (Image: DOE)

Crews at the Department of Energy’s Hanford Site, near Richland, Wash., have begun heating up the first of two 300-ton melters that will be used to vitrify mixed low-level radioactive and chemical tank waste. According to the DOE’s Office of Environmental Management (EM), initiating and completing the heating of the melter is a critical step to commissioning Hanford’s Waste Treatment and Immobilization Plant (WTP), which will treat and stabilize the site’s 56 million gallons of tank waste by immobilizing it in glass through the vitrification process.

The Effluent Management Facility, part of the Waste Treatment and Immobilization Plant at the Hanford Site. (Photo: Bechtel National)

This spring, the U.S. Government Accountability Office (GAO) released an insightful report reviewing and summarizing the status and performance of the largest projects and operations within the Department of Energy’s Office of Environmental Management (EM), which is responsible for the cleanup of hazardous and radioactive waste at sites and facilities that have been contaminated from decades of nuclear weapons production and nuclear energy research.

Retention basins at the Liquid Effluent Retention Facility on the Hanford Site, as seen in September 2021, at top, and recently with the nearly completed Basin 41 on the far left. (Photo: DOE)

Work is nearing completion on a fourth basin needed to ensure adequate storage for wastewater during tank waste treatment on the Department of Energy’s Hanford Site, in Washington state.

According to the DOE, its operations contractor Washington River Protection Solutions (WRPS) has made significant progress on Basin 41 at the Liquid Effluent Retention Facility (LERF) since concrete was first poured for the perimeter one year ago.

Video: Watch this time-lapse video of the LERF Basin 41 construction.

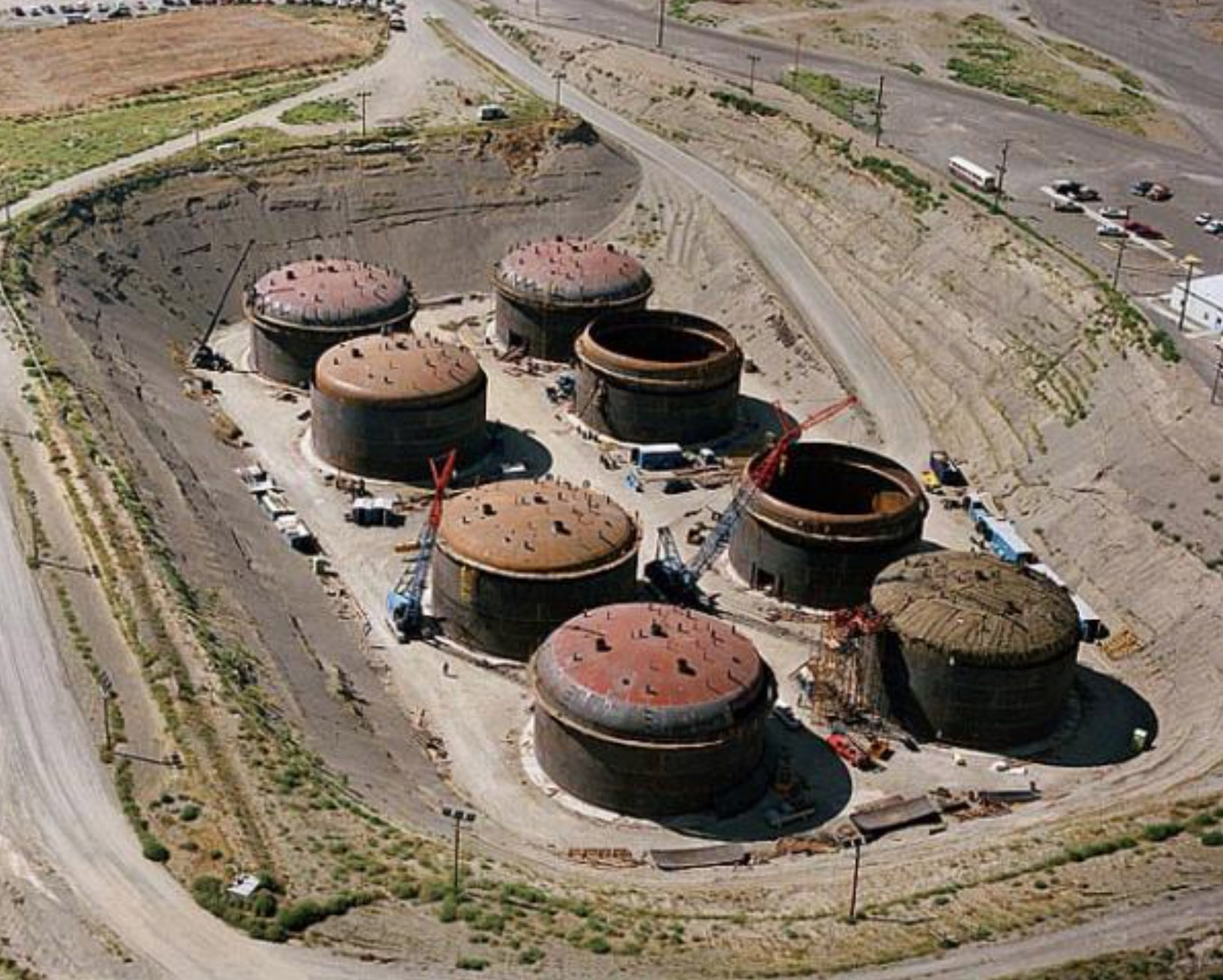

The B Farm underground waste tank area at Hanford. (Photo: DOE)

Washington state’s Department of Ecology and the U.S. Department of Energy have agreed on a plan for how to respond to two underground tanks that are leaking radioactive waste, as well as any future tank leaks, at the Hanford Site near Richland, Wash.

In April 2021, following a year-long leak assessment, the DOE announced that Hanford’s Tank B-109 is leaking waste into the surrounding soil. Tank T-111 was discovered to be leaking in 2013. Currently, Tank B-109 is leaking about 1.5 gallons of waste per day, and Tank T-111 is leaking less than a gallon a day, according to the DOE.