Nine Mile Point (Photo: Constellation Energy)

Exelon Generation has received a grant from the Department of Energy to explore the potential benefits of on-site hydrogen production and has chosen its Nine Mile Point nuclear power plant as the demonstration site, the company announced on Wednesday. (In 2019, Exelon received a conditional commitment from the DOE to co-fund a hydrogen electrolyzer demonstration at a nuclear plant.) Located in Scriba, N.Y., Nine Mile Point consists of two boiling water reactors—the 620-MWe Unit 1 and the 1,287-MWe Unit 2.

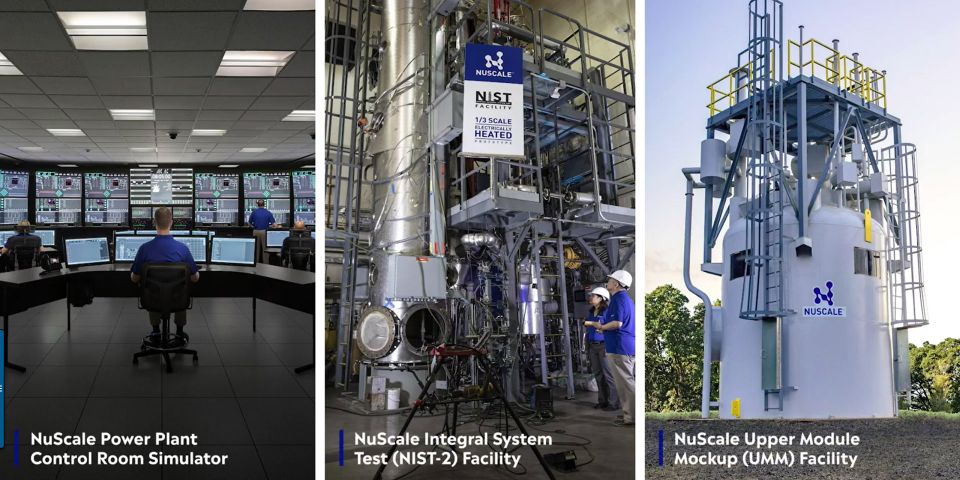

A still image from a three-part video tour of NuScale’s facilities. (Photos: NuScale Power)

NuScale Power has signed a memorandum of understanding with Xcel Energy to explore the feasibility of the utility’s serving as a plant operator at NuScale plants, the Portland, Ore.-based small modular reactor developer announced earlier this week.

Xcel owns and, through subsidiary Northern States Power Company, operates Minnesota’s two nuclear plants, Monticello and Prairie Island. The Monticello facility houses one 671-MWe boiling water reactor, while Prairie Island has twin 550-MWe pressurized water reactors.

Advanced reactor demonstration projects on the horizon will challenge the nuclear supply chain in new ways. A vital component that can be east to overlook is the need for skilled construction, trades, and craft workers. That's why Idaho National Laboratory is forging valuable networks to address these needs.

INL will need technical, innovative, and safety-minded construction personnel for the advanced nuclear projects ahead. Photo: INL

Around the world, researchers in the energy industry are engaging in the work of studying, testing, and developing carbon-free energy solutions. Throughout these circles, many scientists and engineers are embracing the possibilities of advanced nuclear technologies, including small modular reactors and microreactors. While these innovative technologies are poised to address some of the nation’s biggest concerns, they also present their own unique challenges, including the need for a large and talented workforce within the construction industry.

Fortunately, the state of Idaho and its key nuclear players are well-equipped for this challenge. In southeastern Idaho, home of Idaho National Laboratory, strong partnerships throughout the region have forged networks between the lab and the educational institutions, employers, trades, and unions that are working to establish this highly specialized nuclear talent pipeline.

Digital engineering, which uses advanced technologies to capture data and optimize design in a digital environment, is being applied for the first time to a DOE nuclear project and has already realized substantial benefits.

With a new generation of nuclear reactors in the works, Idaho National Laboratory has embraced digital engineering (DE) as a means of achieving the same efficiencies that companies in the private sector have been able to realize in everything from concert halls to aircraft engines.

DE—using advanced technologies to capture data and craft design in a digitized environment—has been evolving since the 1990s. For Mortenson Construction, a worldwide construction firm, using virtual design and construction resulted in a cumulative 600 days saved over 416 projects and a 25 percent increase in productivity. By building digital twins for assets, systems, and processes, DE has avoided more than $1.05 billion in customer, production, and mechanical losses.

Leaders at INL recognized in 2018 that DE could be useful in the design and construction of new commercial and test reactors. Managing construction costs, timing, and performance will be essential to maintain U.S. competitiveness.