Next Generation MG Control Power Cabinets Installed

Westinghouse Parts Business (WPB) is proud of the first next generation Motor Generator (MG) Set System fully operational at Palo Verde Generating Station. The team completed a first-of-a-kind (FOAK) implementation and installation at the power plant operated by Arizona Public Service (APS), including the next generation MG Control Power Cabinets and new MG Sets. Additionally, Westinghouse installed the new ARCH (Advanced Rod Control Hybrid) system. These systems were installed in a single outage providing additional synergies and cost savings to operations.

December 2, 2022, 3:03PMNuclear NewsBrian Dassatti, Kamila Blain, and Jenn Sinkiewicz Teledyne FLIR PackBot® conducts visual inspections in a hazardous area.

Mobile unmanned systems, also known as MUS, encompass a range of robotic devices, including drones, ground vehicles, crawlers, and submersibles. They are used for a wide range of industrial and defense applications to automate operations and assist humans or completely remove human workers from hazardous conditions. Robotics are ubiquitous in industrial manufacturing. Military robots are routinely employed in combat support applications, such as reconnaissance, inspection, explosive ordnance disposal, and transportation. Drones are used in many industries for security and monitoring, to conduct aerial inspections or surveys, and to capture digital twins. Wind and solar farms use MUS technologies for day-to-day operations and maintenance.

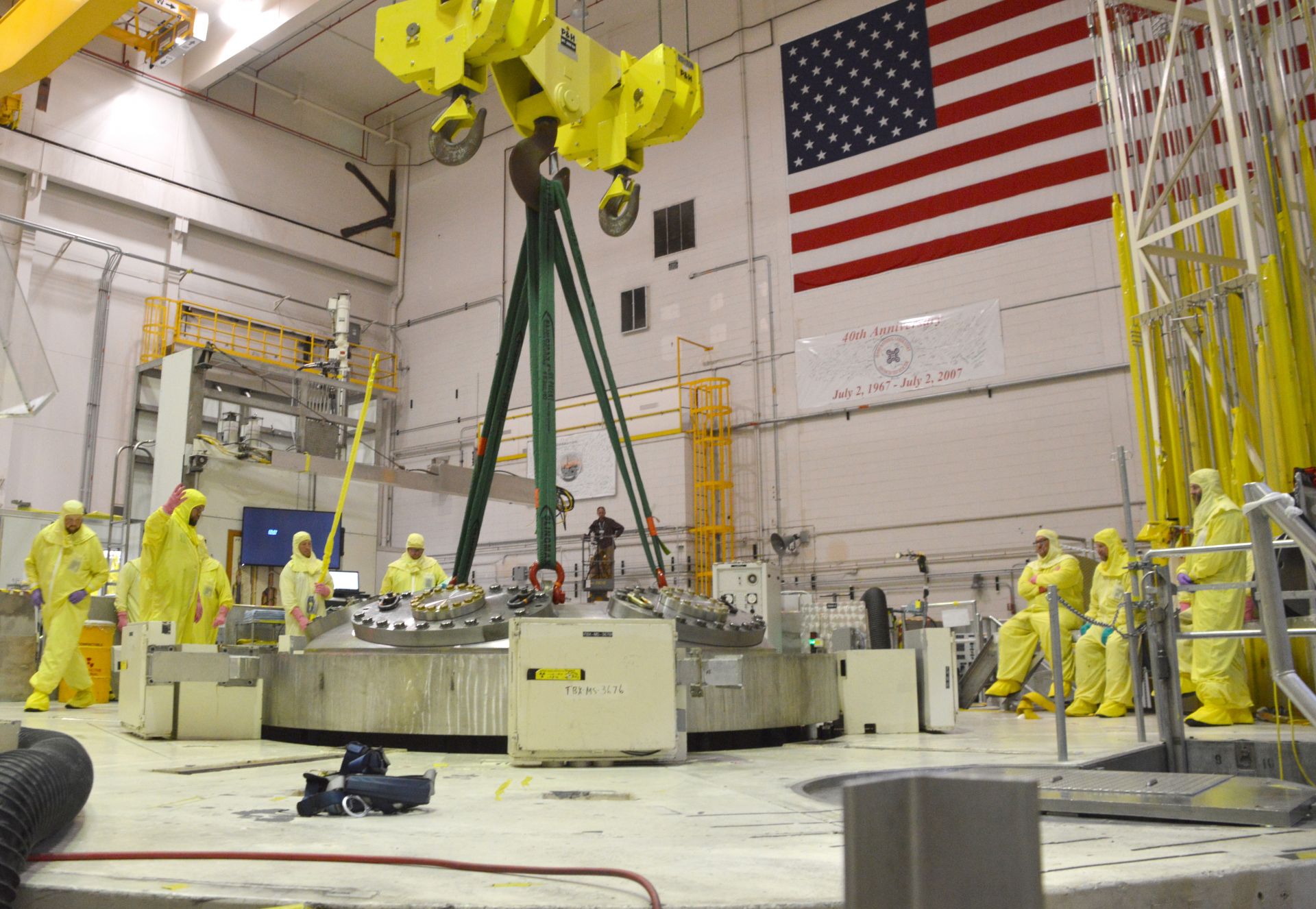

October 8, 2021, 3:31PMUpdated December 31, 2021, 4:16PMNuclear NewsJoseph Campbell; Photos by Joseph Campbell and Peter Ritchie, INL The first of three phases of the Advanced Test Reactor’s sixth core overhaul culminated with the removal of the 31-ton stainless steel vessel top head on July 1, for the first time since 2004. The vessel and top head underwent extensive inspection, laser scanning, and upgrade as part of the overhaul. (Photo: JC)

As 2021 closes, Nuclear News is taking a look back at some of the feature articles published each month in the magazine. The October issue focused on plant maintenance and outage management with multiple articles looking at efficient ways to deal with plant maintenance. The article below looks at the herculean effort by INL to lead a full overhaul of the Advanced Test Reactor--a task that happens about every 10 years.

Out of the frenzy of nuclear technology and engineering development at the height of the Atomic Age, a few designs stand out above the rest—designs so innovative that they would not be surpassed for years, or even decades. An example of this unsurpassed design brilliance exists in the form of Idaho National Laboratory’s Advanced Test Reactor.

“ATR is really a beautiful machine,” said Sean O’Kelly, associate lab director for the ATR Complex. “The elegant cloverleaf core and control systems were a stroke of genius that solved just about every key problem of test reactor design. The designers’ solutions to those problems give us a testing capacity and flexibility that have yet to be matched.”

Allied Power has acquired Dominion Engineering, Inc. (DEI), Allied announced last week. Financial terms of the deal were not disclosed.

Allied Power has acquired Dominion Engineering, Inc. (DEI), Allied announced last week. Financial terms of the deal were not disclosed.