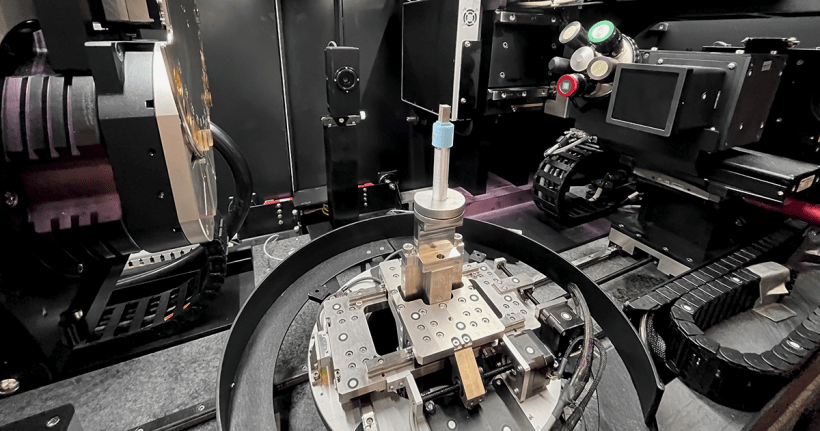

An enhanced CT scan process developed at ORNL can cut the time required to examine 3D-printed parts by one sixth. (Image: DOE)

A software algorithm developed at Oak Ridge National Laboratory has reduced the time needed to inspect 3D-printed parts for nuclear applications by 85 percent, the Department of Energy announced on November 1, and that algorithm is now being trained to analyze irradiated materials and nuclear fuel at Idaho National Laboratory.

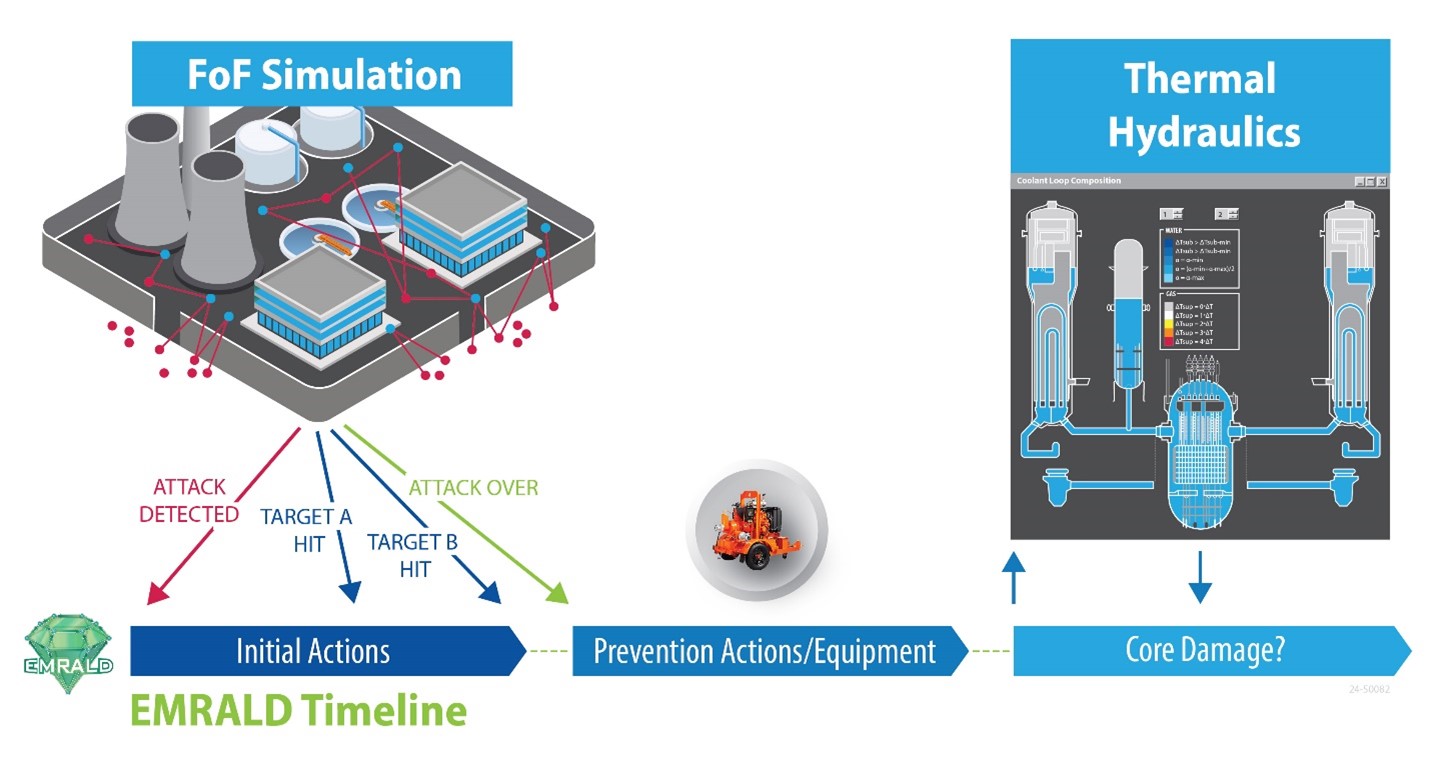

The MASS-DEF framework with prevention actions and timelines modeled in EMRALD software interacting with force-on-force (FoF) simulation and thermal hydraulics models. The risk-informed modeling in the MASS-DEF framework integrates physical security effectiveness analysis with safety measures, such as time to core damage. (Graphic: INL)

Today’s nuclear power plants are the nation’s largest source of carbon-free energy, but they come with high operating and maintenance costs.

Competition from other sources, especially natural gas, coupled with low electricity prices, has resulted in the closure of some plants in the last decade due to economic reasons.

One way to alleviate these economic pressures is to reduce the cost of operating nuclear power plants, including the costs associated with physical security.

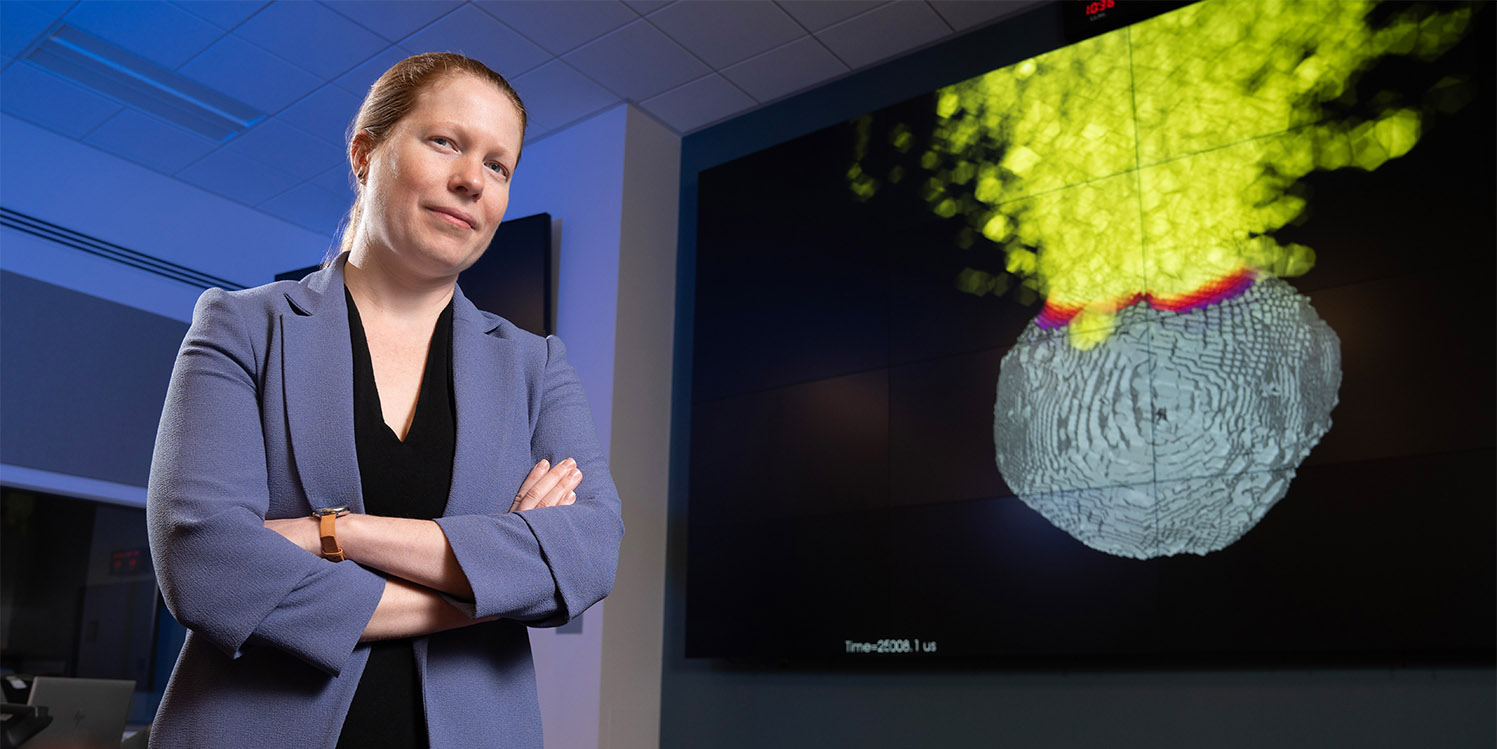

LLNL physicist Mary Burkey developed a novel approach to simulating the energy deposition from a nuclear device on an asteroid’s surface. (Photo: LLNL)

The same high energy density that makes nuclear energy a clean and efficient source of power could make it a good alternative to defend the planet against catastrophic asteroid impacts. NASA demonstrated the world’s first planetary defense technology in September 2022 by deliberately crashing a “kinetic impactor”—a heavy, box-like spacecraft—into an asteroid. Now, researchers at Lawrence Livermore National Laboratory have developed a new tool to model how a nuclear device could deflect—or even destroy—an asteroid threat to Earth in a more efficient and controlled way.

A screenshot taken from a INL video demonstrating MAGNET and its digital twin. (Source: INL)

Researchers at Idaho National Laboratory (INL) recently performed their first digital twin test of the Microreactor Agile Non-nuclear Experimental Testbed (MAGNET) and captured the demonstration in a video posted July 14. The digital twin—a virtual representation of a microreactor—was built using advancements in remote monitoring, autonomous control, and predictive capabilities that could help lower operating costs of microreactor technologies and enhance their safety.