Joe Dixon

Hubert Hafen

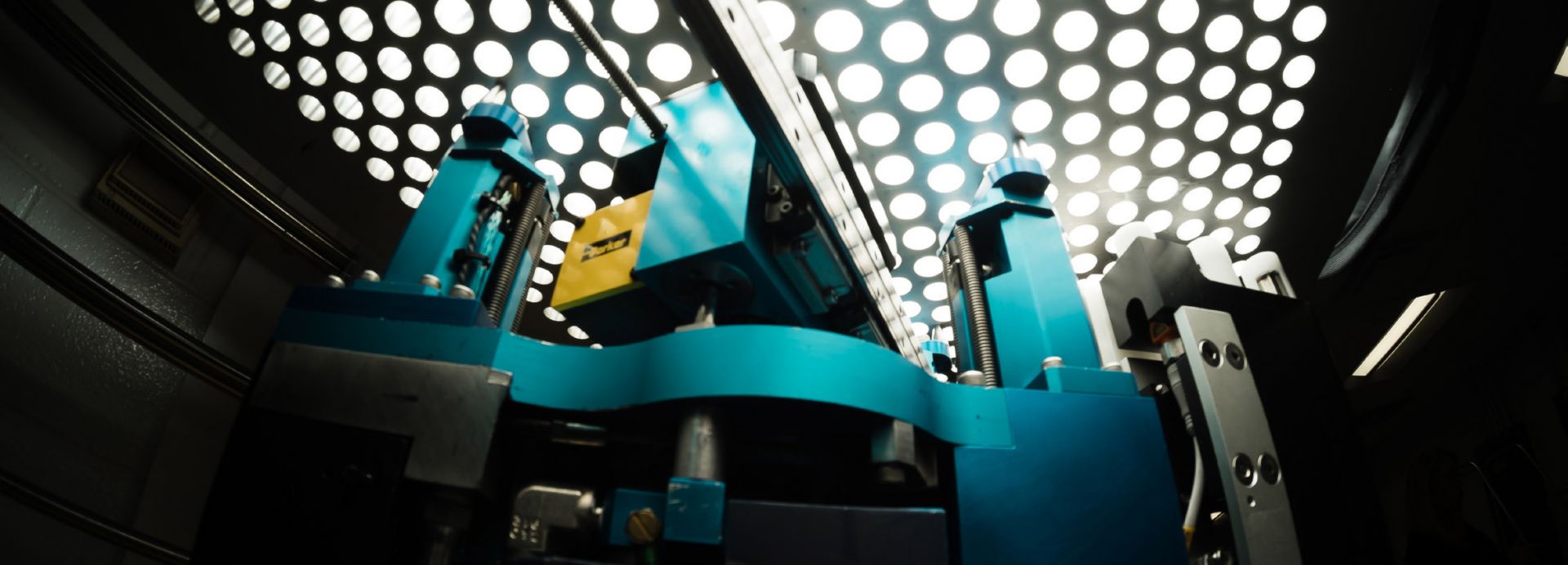

Wälischmiller Engineering (HWM), of Markdorf, Germany, has joined forces with NuVision Engineering (NVE) to form NuVision-Wälischmiller under parent company Carr’s Engineering. The NVE-HWM team develops, demonstrates, and deploys engineered remote systems and robotics to meet the high safety standards, quality requirements, and challenging demands of the nuclear industry.

HWM specializes in remote-handling and robotic solutions for hazardous applications. Since 1946, HWM has been delivering a range of remote-handling solutions, including precision manipulators, tools, and controllers, to the nuclear industry.

NVE, founded in 1971, is headquartered in Pittsburgh, Pa., with major operational facilities in Charlotte, N.C. The company delivers engineered solutions and services to its customers in the nuclear markets of commercial power, research, isotope production, and government cleanup sectors. NuVision develops, demonstrates, and deploys technology-based solutions that help extend the life and safe operation of power plants, improve new plant designs, and remediate government-owned legacy waste sites.

Joe Dixon is the robotics director at NVE. For nearly 20 years, he has provided solutions for the global nuclear industry and has conceived, designed, fabricated, deployed, and managed teams for advanced robotics, isotope production, scientific research, decommissioning, energy production, process maintenance, and remote handling. Having worked on large projects around the world, Dixon is one of the industry’s leaders in remote-handling and robotics technologies.

Hubert Hafen is the chief technology officer for HWM. With more than 30 years of experience in the nuclear industry, Hafen has served as chief engineer and project manager for a large number of international remote-handling projects, such as remote-handling equipment for the decommissioning of the Greifswald nuclear power plant in Germany, the decommissioning of the reprocessing plant in Karlsruhe, Germany, planning for the remote equipment for the ITER project, and several remote-handling projects in Japan, Russia, China, the United Kingdom, France, and Germany. His ability to present clients with problem solving has made him renowned in the robotics world.

Dixon and Hafen talked recently with Nuclear News editor-in-chief Rick Michal about what is new in robotics and remote-handling systems.