The Defense Waste Processing Facility at the Savannah River Plant. (Photo: SRS)

In 1989, the Savannah River Plant was renamed the Savannah River Site. It was originally established in 1950 near Aiken, S.C., to produce nuclear materials for the nation, primarily for defense purposes. The site consisted of a heavy water production plant, three fuel fabrication facilities, five production reactors, two nuclear separation facilities, waste management facilities, tritium processing facilities, and the Savannah River National Laboratory. The main isotopes produced were, by priority, tritium, plutonium-238, and plutonium-239.

SRS’s apprenticeship program recognized current apprentices and program partners during a luncheon at Aiken Technical College. (Photo: DOE)

The Department of Energy’s Savannah River Site in South Carolina recently joined in the nationwide celebration of the Department of Labor’s 10th annual National Apprenticeship Week, spotlighting the progress and diversity of its apprenticeship program that spans 27 occupations.

Click here to watch a video highlighting the SRS Apprenticeship Program.

The STEM Like a Girl event was held at the Ruth Patrick Science Education Center in Aiken, S.C. (All photos: DOE)

Nearly 60 eighth graders from schools across the central Savannah River area recently gathered at the Ruth Patrick Science Education Center in Aiken, S.C., for the Savannah River Site’s “STEM Like a Girl—Introduce a Girl to Engineering and IT” event. This initiative is designed to inspire the next generation of female engineers and STEM leaders.

The Flyability Elios 3 model drone for the SRS tank inspection program. (Photo: SRS)

The Department of Energy’s Office of Environmental Management will soon, for the first time, begin using drones to internally inspect radioactive liquid waste tanks at the department’s Savannah River Site in South Carolina. Inspections were previously done using magnetic wall-crawling robots.

TRU drum storage in the Solid Waste Management Facility in 1998 before WIPP opened (left) and in 2024 (right). (Photo: DOE)

The Solid Waste Management Facility (SWMF) at the Savannah River Site saw a large reduction of transuranic (TRU) waste in fiscal year 2024, achieving the highest volume of TRU waste shipped out of state by the facility in the past 10 years, according to the Department of Energy.

TRU waste typically consists of protective clothing, tools, rags, equipment, and miscellaneous items contaminated with small amounts of plutonium and other heavy elements.

The Salt Waste Processing Facility recently surpassed a production milestone by processing more than 10 million gallons of high-level waste at the Savannah River Site. (Photo: DOE)

SRNS’s Erika Baeza-Wisdom gives an overview of SRNS pit production to UTEP students. (Photo: SRNS)

Savannah River Nuclear Solutions (SRNS), the managing and operating contractor at the Department of Energy’s Savannah River Site in South Carolina, and the DOE’s Los Alamos National Laboratory in New Mexico are partnering with multiple universities to develop next-generation technology and personnel pipelines to advance the DOE National Nuclear Security Administration’s two-site pit production mission.

Participants visited the Augusta Convention Center to meet with representatives of hundreds of colleges and universities. (Photo: SRS)

More than 4,700 attendees recently filled the Augusta Convention Center in Georgia in search of higher education and career opportunities during the Savannah River Site Central Savannah River Area College Night. The Department of Energy’s Savannah River Site is in South Carolina.

Idaho National Laboratory employees consult on a microgrid at Utah’s Dugway Proving Ground. Two solar projects were selected for development on INL land. (Photo: INL)

On July 28, 2023, the Department of Energy launched its Cleanup to Clean Energy initiative, an effort to repurpose underutilized DOE-owned property—portions of which were previously used in the nation’s nuclear weapons program—into the sites of clean-energy generation.

SRS liquid waste contractor Savannah River Mission Completion will use drones equipped with cameras to inspect the cleaning status of waste tanks at the site. (Photo: DOE)

The Department of Energy’s Office of Environmental Management will begin using drones for the first time to internally inspect radioactive liquid waste tanks at the department’s Savannah River Site in South Carolina. Inspections were previously done using magnetic wall-crawling robots.

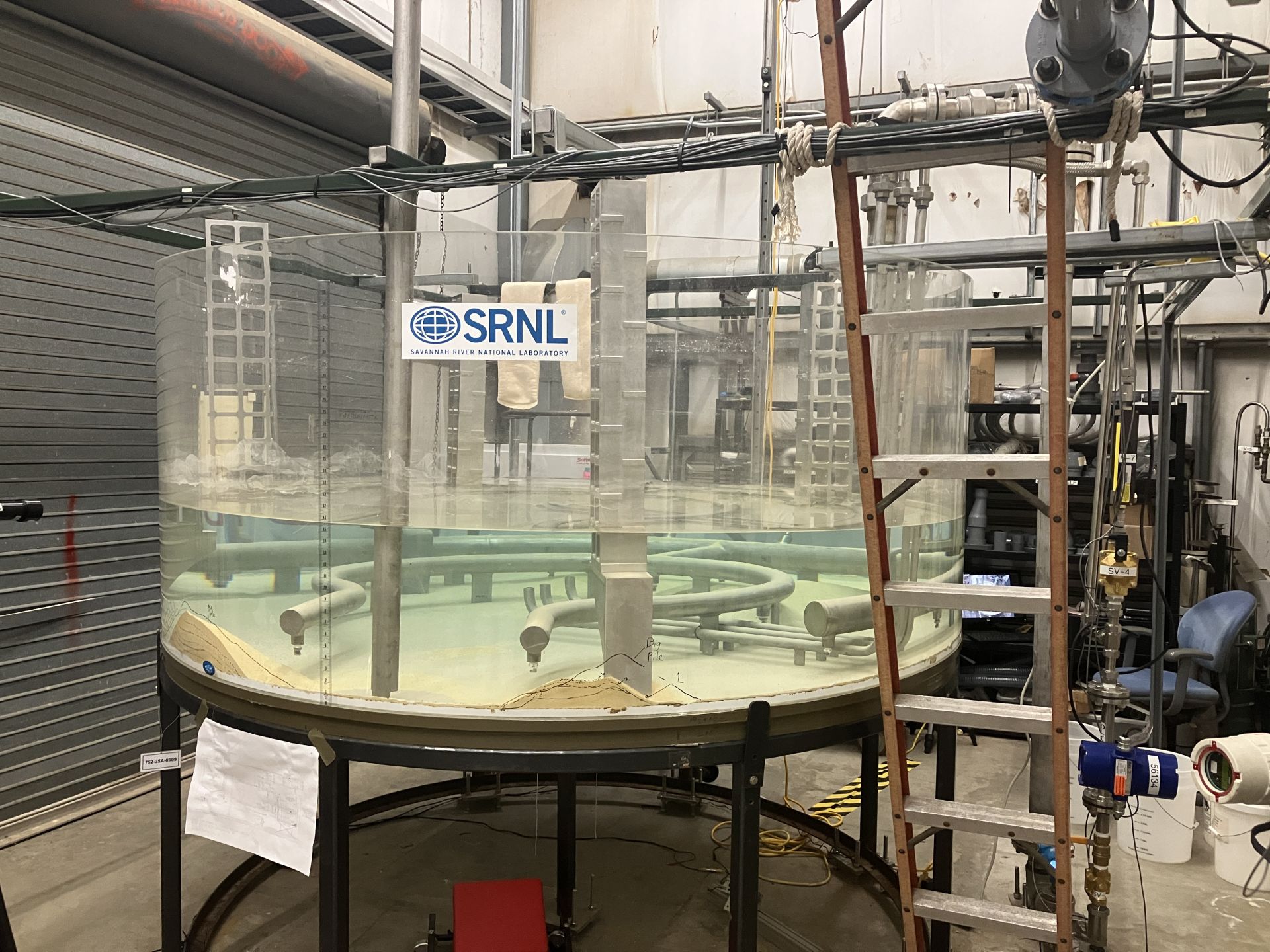

A mock-up model at SRNL was used to demonstrate a full-scale jet cleanout system to remove undissolved material from the H Canyon electrolytic dissolver. (Photo: DOE)

A collaboration between Savannah River Nuclear Solutions (SRNS) and Savannah River National Laboratory (SRNL) is making progress toward processing non-aluminum spent nuclear fuel (NASNF) as part of the site’s accelerated basin de-inventory mission. SRNL is the managing and operating contractor at the Department of Energy’s Savannah River Site in South Carolina.

The D Area Groundwater Treatability Study project team assesses artesian flow into injection well at the Savannah River Site. (Photo: SRNS)

Savannah River Nuclear Solutions (SRNS), the management and operations contractor for the Department of Energy’s Savannah River Site, announced that it has injected more than 100 million gallons of clean artesian well water to neutralize shallow groundwater contamination underneath 33 acres of a former coal storage yard and the associated runoff basin at the site in South Carolina. According to Ashley Shull, senior scientist for the project, “100 million gallons is nine times more water than [is] contained in the Georgia Aquarium in Atlanta.”

The original 1950s-era condenser is lifted out of the GPE system by a 100-ton crane at SRS's H Canyon chemical separations facility. (Photo: DOE)

Workers at the Savannah River Site have recently completed the replacement of a piece of equipment that the Department of Energy said in a July 31 press release is “essential for operations in the site’s H Canyon chemical separations capable facility.”

Aecon-Wachs workers performed the D&R of equipment and commodities from the plutonium processing facility at SRS. ( Photo: SRS)

A major milestone has been reached in the construction of a plutonium pit production facility at the Savannah River Site, located near Aiken, S.C.

After 18 months of work involving local trade unions, the dismantlement and removal (D&R) of commodities and equipment throughout the Savannah River Plutonium Processing Facility (SRPPF), previously installed by the Mixed Oxide (MOX) project, was completed in June 2024, the Department of Energy reported on July 24.

SRS Apprenticeship Program graduates Terrence Tillman (far right) and Shanterra Hughes share their recent apprenticeship experiences with NPR host David Brancaccio (center) and NPR sound engineer Rebekah Wineman. (Photo: DOE)

A new radio series on National Public Radio’s “Marketplace Morning Report” recently highlighted career opportunities and job training at the Department of Energy’s Savannah River Site.

To listen to the radio segment, click here.

SRS firefighters responded to a staged scene outside of K Area’s Criticality Control Overpack pad. The firefighters followed an Incident Action Plan to maximize the safety of responders and role-playing victims for effective extraction. (Photo: DOE/SRNS)

Earlier this month, nearly 250 personnel at the Department of Energy’s Savannah River Site in South Carolina took part in an annual exercise to test preparedness for a radiological release and contamination emergency.