ANS's “Powering Our Future: The Coal to Nuclear Opportunity” panel discussion featured (top left, clockwise) Jessica Lovering, Patrick Burke, Kenya Stump, Andrew Griffith, Christine King, and Carol Lane. (ANS screenshot)

Since at least June of last year—when TerraPower and PacifiCorp announced plans to site the Natrium reactor demonstration project at one of Wyoming’s retiring coal plants—the concept of repurposing those plants to host nuclear reactors has been a popular topic of conversation among the energy cognoscenti.

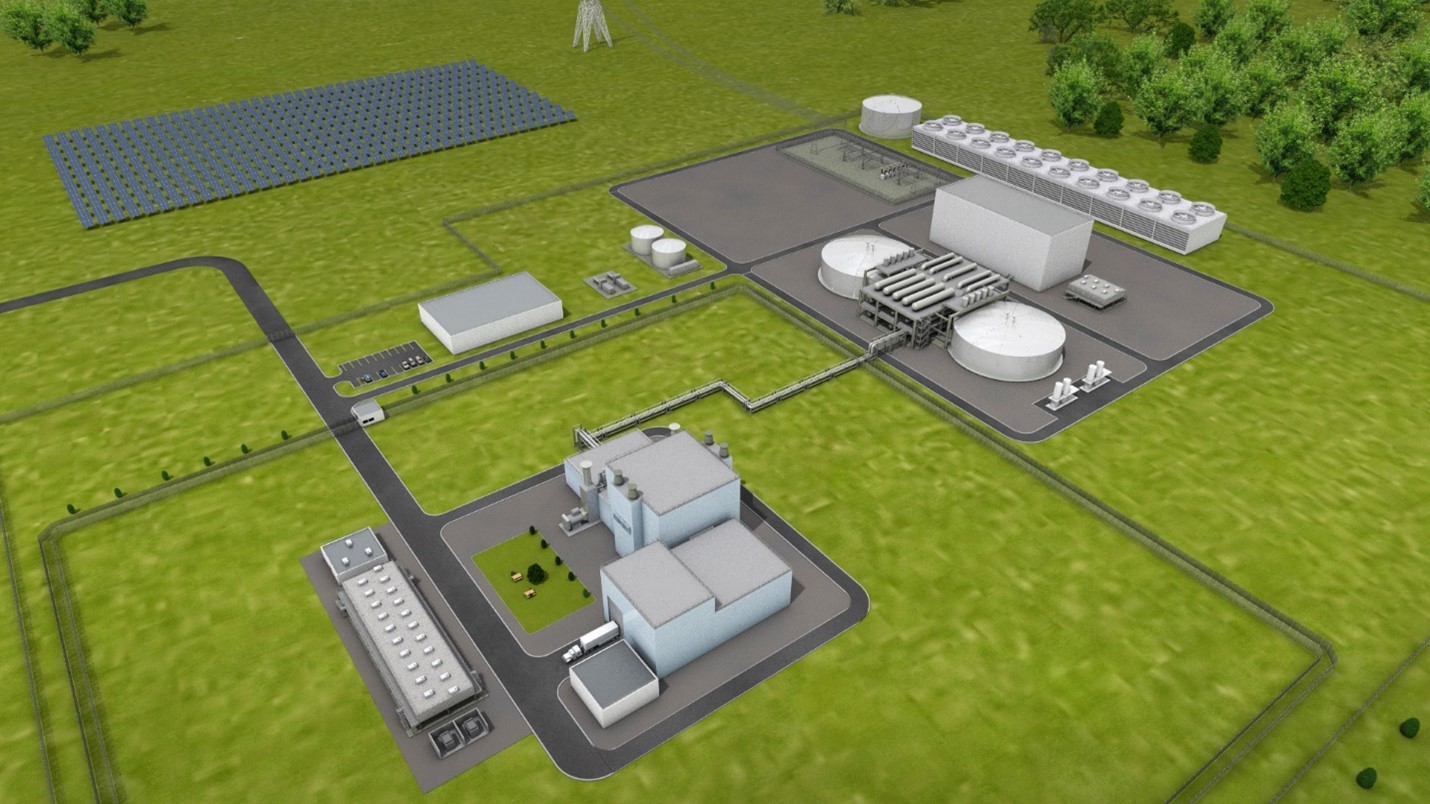

An artist’s rendering of Natrium. (Image: TerraPower)

Nuclear technology firm TerraPower and utility partner PacifiCorp have launched a study to evaluate the feasibility of deploying up to five additional Natrium reactor and integrated energy storage systems in the utility’s service territory by 2035, the companies announced yesterday. (PacifiCorp’s business units—Pacific Power and Rocky Mountain Power—serve customers in California, Oregon, and Washington, and in Idaho, Utah, and Wyoming, respectively.)

Natrium Fuel Facility groundbreaking. (Photo: GNF-A)

Global Nuclear Fuel–Americas (GNF-A) and TerraPower announced their plans to build a Natrium fuel fabrication facility next to GNF-A’s existing fuel plant near Wilmington, N.C, on October 21. While more than 50 years of fuel fabrication at the site have supported the boiling water reactor designs of GE (GNF-A’s majority owner) and GE Hitachi Nuclear Energy (GEH), the Natrium Fuel Facility will produce metallic high-assay low-enriched uranium (HALEU) fuel for the sodium fast reactor—Natrium—that TerraPower is developing with GEH.

The Integrated Effects Test at TerraPower’s laboratory in Everett, Wash. (Photo: Southern Company/TerraPower)

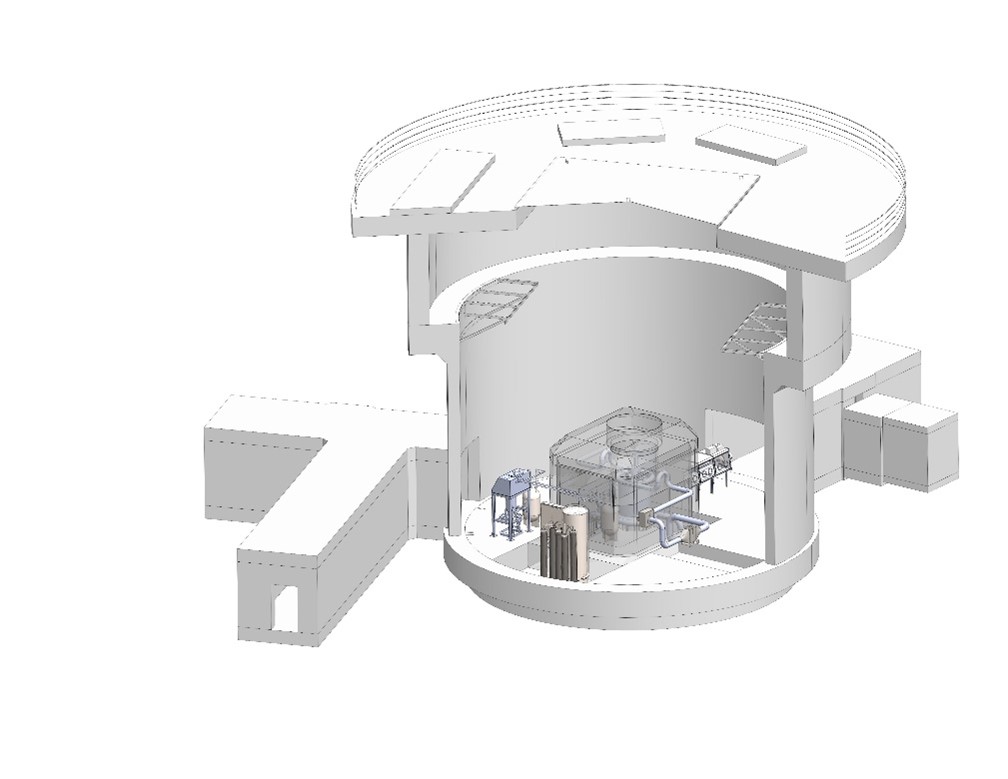

“The world's largest chloride salt system developed by the nuclear sector” is now ready for operation in TerraPower’s Everett, Wash., laboratories. Southern Company, which is working with TerraPower through its subsidiary Southern Company Services to develop molten chloride reactor technology, announced on October 18 that the Integrated Effects Test (IET) was complete. The multiloop, nonnuclear test infrastructure follows years of separate effects testing using isolated test loops, and it was built to support the operation of the Molten Chloride Reactor Experiment (MCRE) at Idaho National Laboratory that the companies expect will, in turn, support a demonstration-scale Molten Chloride Fast Reactor (MCFR).

A rendering of the MCRE. (Image: Southern Company)

The Gateway for Accelerated Innovation in Nuclear (GAIN) awarded vouchers to Orano Federal Services and TerraPower on June 22, giving them access to specialized facilities and expertise at Department of Energy national laboratories. Orano is partnering with Oak Ridge National Laboratory on a new technical study that updates the physical chemistry limits for the safe transport of uranium hexafluoride (UF6) gas enriched up to 10 percent in existing shipping containers, and TerraPower is turning to Los Alamos National Laboratory’s neutron testing capabilities to measure the properties of chlorine isotopes and determine how they will behave in the Molten Chloride Reactor Experiment (MCRE).

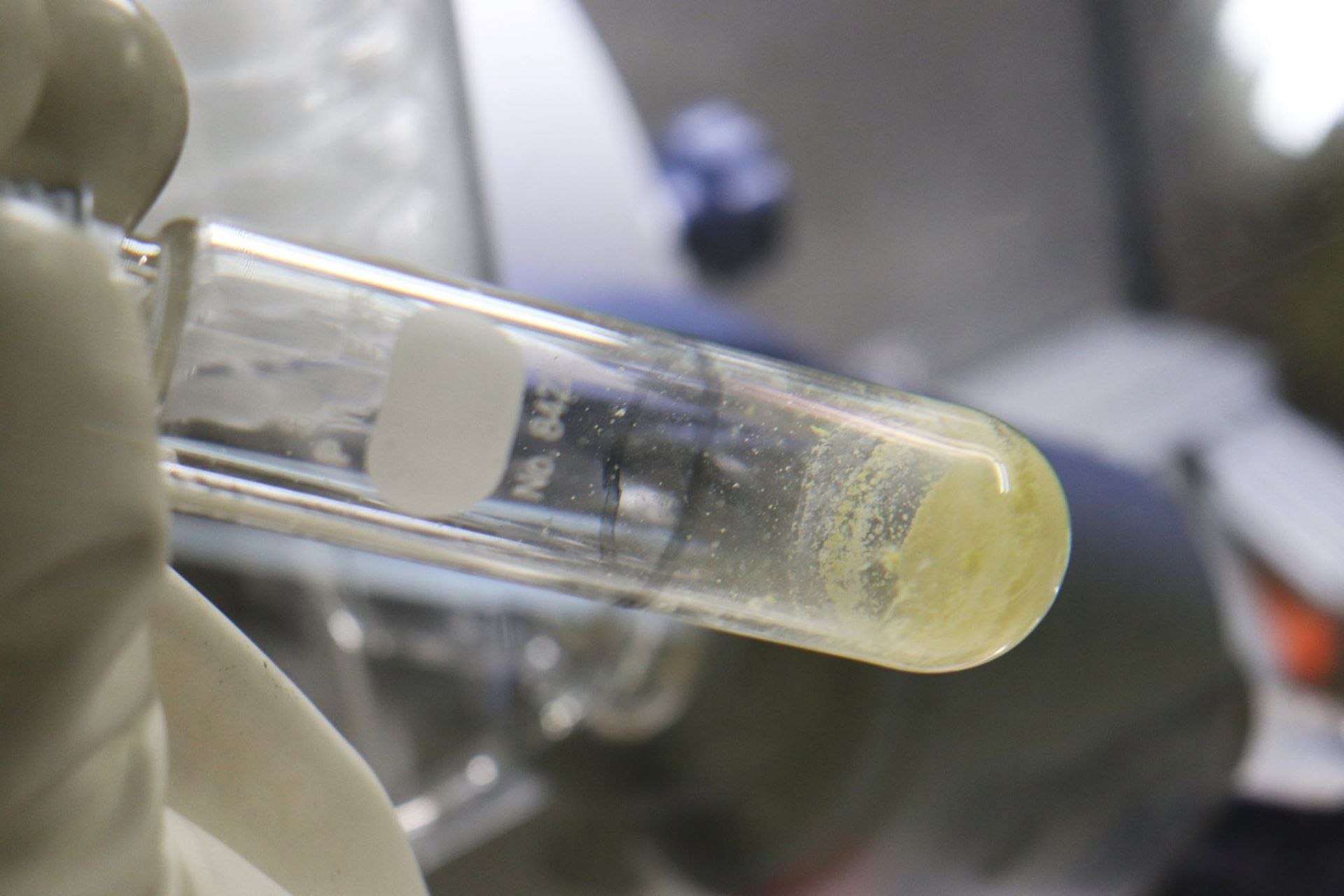

The DOE and a contractor recently succeeded in disposing of Oak Ridge’s low-activity U-233, but not before recovering Th-229 from the material.

A vial containing Th-299 extracted from uranyl nitrate.

This past October, the Department of Energy’s Oak Ridge Office of Environmental Management (OREM) and its contractor Isotek successfully completed processing and disposing the low-dose inventory of uranium-233 stored at Oak Ridge National Laboratory (ORNL), ending a two-year effort that has eliminated a portion of the site’s legacy nuclear material and provided rare nuclear isotopes for next-generation cancer treatment research.

Members of the Xe-100 reactor protection system team and the first set of prototype equipment. (Photo: X-energy)

X-energy, developer of the Xe-100 small modular reactor, has delivered the first of four sets of equipment for the Xe-100 reactor protection system (RPS) prototype, marking the latest milestone in the company’s efforts under the Department of Energy’s Advanced Reactor Demonstration Program (ARDP).

A screen shot of a YouTube video of the DOE’s U-233 Initial Processing Campaign at Oak Ridge National Laboratory.

Isotek, the Department of Energy contractor responsible for overseeing the inventory of uranium-233 at Oak Ridge National Laboratory and preparing it for removal from the site, said it plans to resume preparations for processing high-dose U-233 in March. The company was forced to suspend its operational readiness review of the Initial Processing Campaign at Oak Ridge in January due to issues related to COVID-19, as well as difficulties operating in colder temperatures.

An advanced nuclear reactor technology park is hoped for the 935-acre Clinch River site. Image: TVA

The Tennessee Valley Authority’s board of directors has given the go-ahead for a program that will explore the development and potential deployment of small modular reactors as part of the utility’s decarbonization strategy.

A rendering of the Natrium plant. (Image: TerraPower)

Natrium, a 345-MWe sodium fast reactor with a molten salt energy storage system, was developed by TerraPower and GE Hitachi Nuclear Energy. TerraPower is planning to build the first Natrium demonstration reactor by 2028 with 50-50 cost-shared funding of about $2 billion from the Department of Energy’s Advanced Reactor Demonstration Program. And for the requisite data and testing of reactor components to support that deployment, TerraPower is looking to Japan—a country with decades of experience developing sodium fast reactor designs and testing infrastructure.

.jpg)