The H9 Hall thruster, developed at UMich’s Plasmadynamics and Electric Propulsion Laboratory. (Image: William Hurley/University of Michigan)

Seeking spacecraft that can “maneuver without regret,” the U.S. Space Force is investing $35 million in a national research team led by the University of Michigan to develop a spacecraft with an onboard microreactor to produce electricity, with some of that electricity used for propulsion. But this spacecraft would not be solely dependent on nuclear electric propulsion—it would also feature a conventional chemical rocket to increase thrust when needed.

Eielson Air Force Base is shown in this screen grab from a video hosted on the base’s website. (Image: DOD)

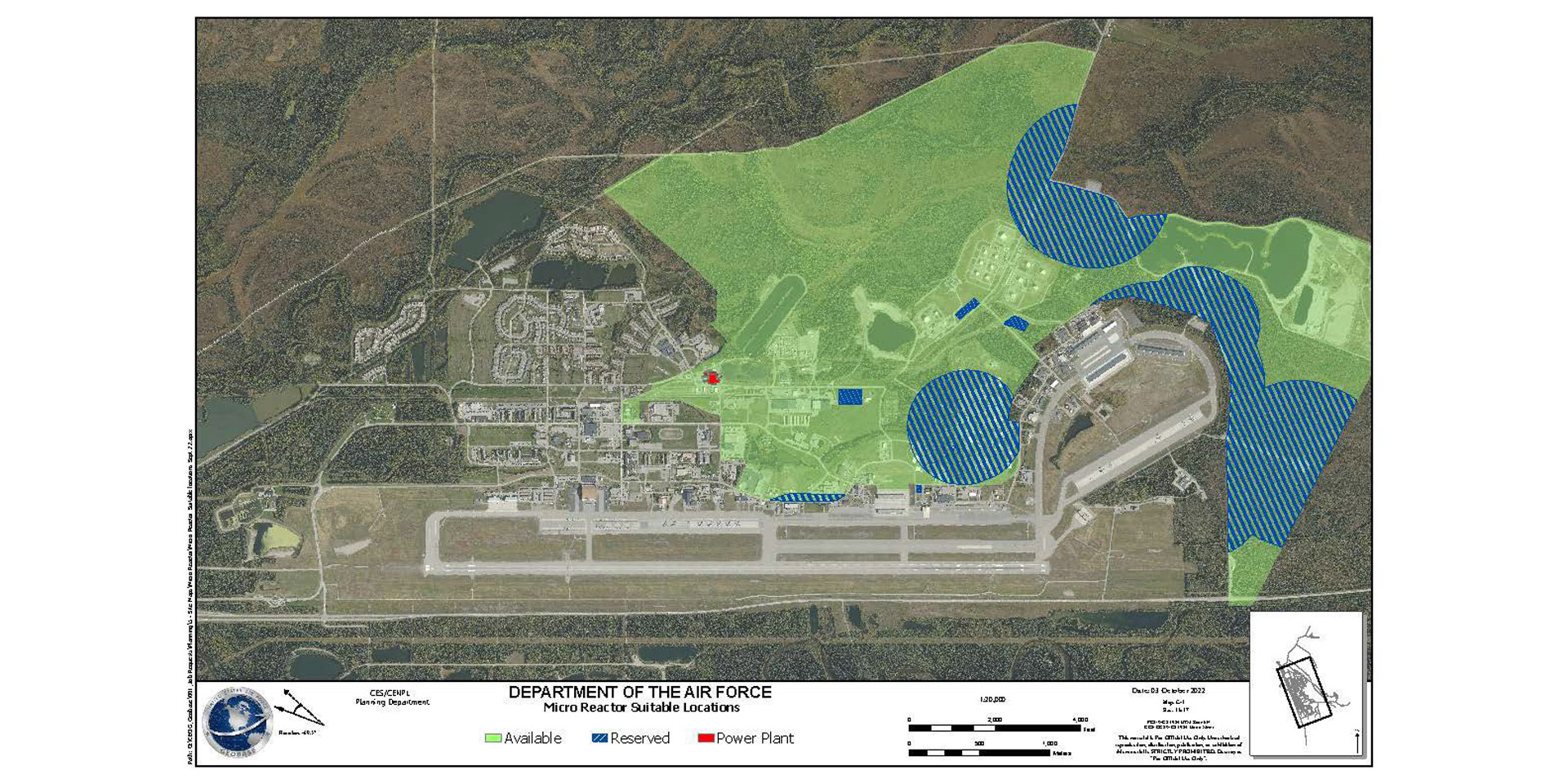

Eielson Air Force Base in central Alaska has been the preferred location to demonstrate the benefits of microreactors to the U.S. Air Force—and by extension the Defense Department—since 2018. Now, a protracted solicitation process is nearing an end, and the Air Force and the Defense Logistics Agency Energy (DLA Energy) expect to announce a final procurement decision by the end of the summer—or about one year after Oklo Inc. announced that it had been tentatively selected to supply a microreactor under a 30-year power purchase agreement.

A map of the potential reactor siting area (in green) at Eielson Air Force Base in Alaska provided during a pre-proposal conference in October 2022. (Graphic: Department of the Air Force)

Plans announced with fanfare sometimes falter in the face of competition or economics. Take NuScale Power’s plans for the Carbon Free Power Project in Idaho: The project was canceled in mid-November by NuScale and its first customer, Utah Associated Municipal Power Systems, after nearly a decade. The significance of that news depends on the observer. NuScale intends to focus on other sites and customers. Competitors may redouble efforts to tout their own designs and customer lists. Media found an opportunity to speculate about the future of advanced nuclear. And while many in the nuclear community believe the momentum in favor of new nuclear deployments is continuing—or even increasing as COP28 continues—others would caution against high hopes and point to the persistent obstacles of regulation, supply chain constraints, and financing costs.

A cutaway image of a below-grade MMR module. (Image: USNC)

Ultra Safe Nuclear has signed a cooperative agreement with the Manila Electric Company (Meralco)—the Philippines’ largest electric distribution utility—to study the potential deployment of one or more of the company’s high-temperature, gas-cooled microreactors in the Philippines. The agreement, signed November 15, builds on a partnership between the two companies that was announced in August.

Concept art of a nuclear thermal propulsion system. (Image: USNC)

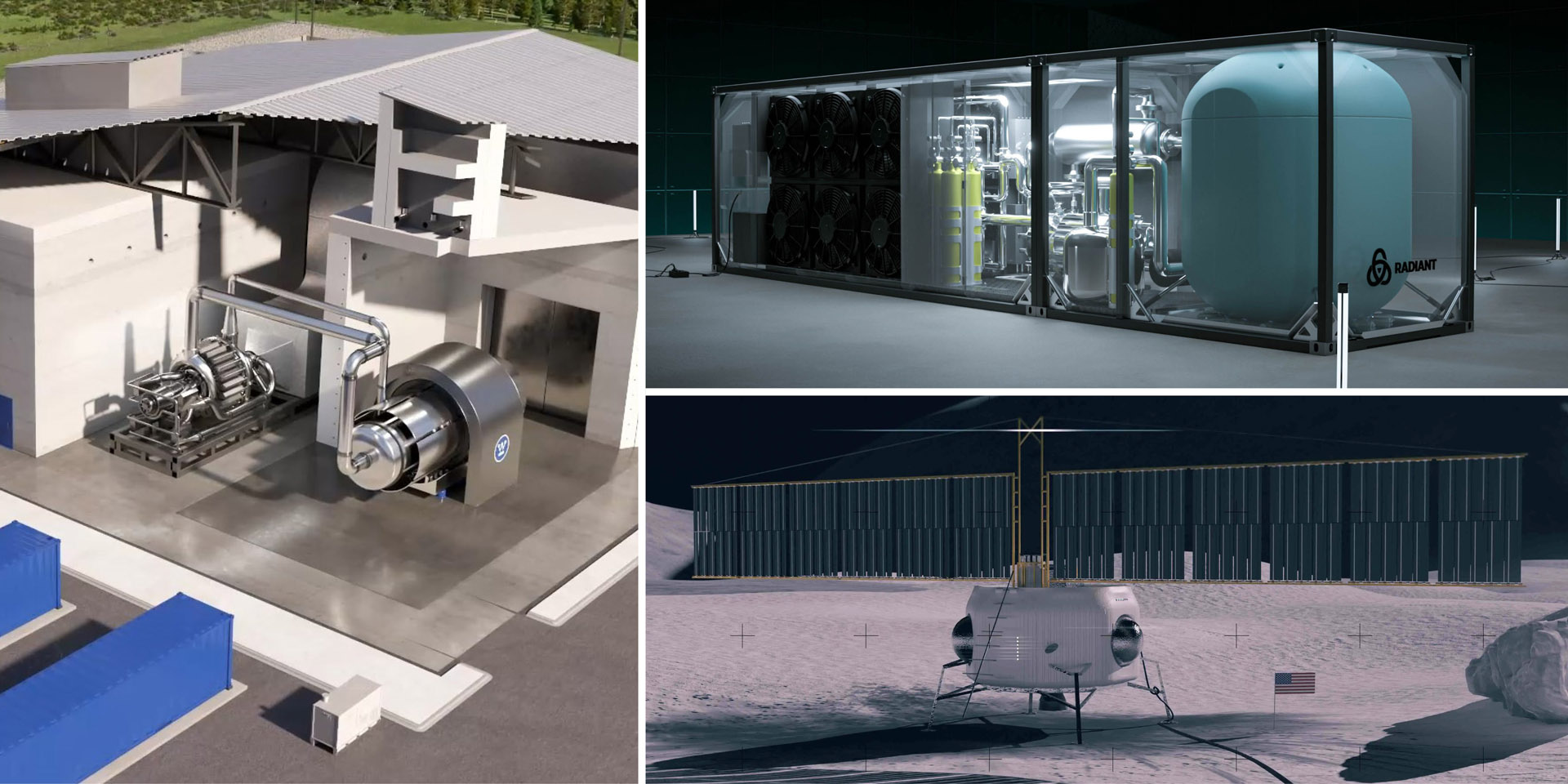

Ultra Safe Nuclear (USNC) announced on October 17 that it had been awarded a contract by NASA to develop and mature space nuclear thermal propulsion (NTP) systems to advance the nation’s cislunar capabilities. Under the contract, USNC says it will manufacture and test proprietary fuel and simultaneously collaborate with its commercial partner, Blue Origin, to mature the design of an NTP engine optimized for near-term civil science and cislunar missions.

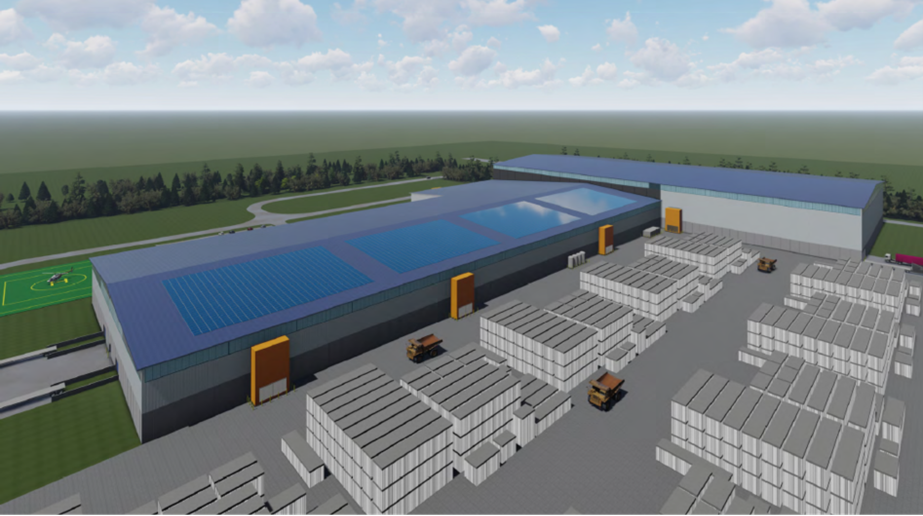

Concept art of the planned Gadsden, Ala., MMR assembly plant. (Image: Ultra Safe Nuclear)

Ultra Safe Nuclear (USNC) announced on June 21 that it has selected the city of Gadsden, Ala., to host a $232 million MMR assembly plant. Modules for the company’s high-temperature, gas-cooled and TRISO-fueled microreactor, dubbed the Micro-Modular Reactor (MMR), would be manufactured, assembled, and tested at the “highly automated facility” once it is in operation.

Local officials, industry representatives, and others joined leaders from AECL, CNL, and GFP to mark the site of Canada’s first microreactor. (Photo: AECL)

From left: Francesco Venneri, chief executive officer of USNC; Hong Hyun-seong, CEO of Hyundai Engineering; and Park Kyung-il, CEO of SK ecoplant, following the signing of an MOU for the construction of a hydrogen micro hub. (Photo: USNC)

Seattle’s Ultra Safe Nuclear (USNC) has announced a partnership with two South Korean firms—Hyundai Engineering and SK ecoplant—for research and development on carbon-free hydrogen production. The three companies signed a memorandum of understanding on April 20 regarding the construction of a “hydrogen micro hub” at SK ecoplant’s headquarters in Seoul’s Jongno-gu district.

Francesco Venneri (left), USNC CEO, and Hyeon Sung Hong, Hyundai Engineering CEO, at a framework agreement signing for MMR project development and deployment.

Representatives of Ultra Safe Nuclear Corporation (USNC) of Seattle, Wash., and Hyundai Engineering of Seoul, South Korea, traveled last week between USNC project sites in Oak Ridge, Tenn., and Ontario, Canada, to sign two agreements extending their collaboration on the deployment of USNC’s high-temperature, gas-cooled Micro Modular Reactor (MMR). The agreements expand on a business cooperation agreement signed in January 2022 and an engineering agreement signed in June, and follow the closure earlier this month of a previously announced $30 million equity investment after its review by the U.S. Treasury Department’s Committee on Foreign Investment in the United States.

Terrani, Huff, and Fleischmann had the honor of cutting the ribbon to celebrate the opening of the Pilot Fuel Manufacturing facility. (Photo: USNC)

Ultra Safe Nuclear Corporation (USNC) celebrated the opening of its Pilot Fuel Manufacturing (PFM) facility in Oak Ridge, Tenn., on August 18 with a ribbon-cutting ceremony and tour attended by assistant secretary for nuclear energy Kathryn Huff, Tennessee lieutenant governor Randy McNally, U.S. Rep. Chuck Fleischmann (R.), representatives from the offices of Sens. Marsha Blackburn (R.) and Bill Hagerty (R.), and other distinguished guests. The next day, radiological operations began at the privately funded facility, which was designed and built in less than twelve months within an existing industrial building purchased by USNC in 2021.

McMaster University, in Hamilton, Ontario, Canada. (Photo: McMaster University)

McMaster University, Ultra Safe Nuclear Corporation (USNC), and Global First Power (GFP) have embarked on a new partnership to study the feasibility of deploying a USNC Micro Modular Reactor (MMR) at McMaster University or an affiliated site. The three partners last week announced a memorandum of understanding that will support research on advanced reactor and small modular reactor technologies in support of Canada’s Net-Zero Emissions by 2050 goal.

Artist’s rendering of USNC spacecraft using EmberCore. (Image: DIU)

The Defense Innovation Unit (DIU), a Department of Defense organization focused on swiftly putting commercial technology to use in the U.S. military, has awarded contracts for two nuclear technologies—compact fusion and radioisotope heat—for spacecraft that could carry a high-power payload and freely maneuver in cislunar space. The objective is to accelerate ground and flight testing and launch a successful orbital prototype demonstration of each approach in 2027.

Ultra Safe Nuclear staff in front of the new pilot fuel fabrication facility in Oak Ridge, Tenn. (Photo: USNC)

Ultra Safe Nuclear Corporation (USNC), an advanced reactor and reactor fuel developer, announced last week that it plans to begin operations this summer at its Pilot Fuel Manufacturing (PFM) facility in Oak Ridge, Tenn., pending the receipt of the requisite state and local permits. The facility is located in the East Tennessee Technology Park, site of the Manhattan Project’s K-25 gaseous diffusion plant. USNC purchased an 8.7-acre site—which included a preexisting industrial building—from Heritage Center LLC in 2021.

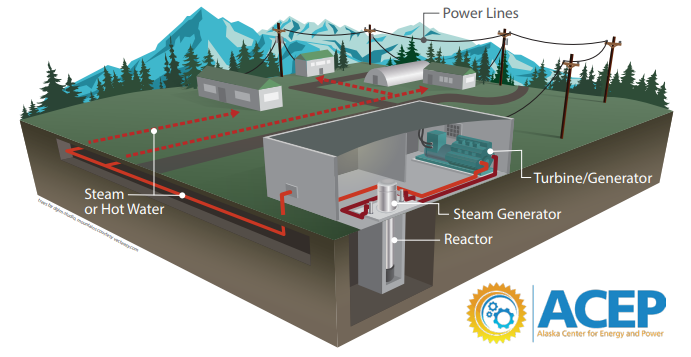

This image is described by the Alaska Center for Energy and Power as a conceptual layout of a generic small modular reactor or microreactor. (Image: ACEP)

Alaska Gov. Mike Dunleavy (R.) introduced “An act relating to microreactors” (SB 177) in the Alaska state legislature on February 1 that would modify existing state law on nuclear energy by specifying that microreactors are not subject to certain nuclear reactor siting and permitting regulations in Alaska. The bill defines a microreactor as an advanced nuclear fission reactor that would be capable of generating no more than 50 MWe.

Kurt Terrani observing a chemical vapor infiltration furnace at ORNL during densification of additively manufactured nuclear-grade silicon carbide. (Photo: Carlos Jones/ORNL/DOE)

Ultra Safe Nuclear Corporation (USNC), a Seattle-based reactor developer, has licensed an additive manufacturing technique developed at the Department of Energy’s Oak Ridge National Laboratory to print refractory materials into structural and core components for the company’s microreactor designs.

Coated uranium fuel kernels, as viewed through a glovebox. (Photo: BWXT)

Nuclear thermal propulsion (NTP) is one technology that could propel a spacecraft to Mars and back, using thermal energy from a reactor to heat an onboard hydrogen propellant. While NTP is not a new concept, fuels and reactor concepts that can withstand the extremely high temperatures and corrosive conditions experienced in the engine during spaceflight are being designed now.

BWX Technologies announced on December 13 that it has delivered coated reactor fuels to NASA for testing in support of the Space Technology Mission Directorate’s NTP project. BWXT is developing two fuel forms that could support a reactor ground demonstration by the late 2020s, as well as a third, more advanced and energy-dense fuel for potential future evaluation. BWXT has produced a videoof workers processing fuel kernels in a glovebox.