Hanford’s HLW Facility under construction in early 2024. (Photo: Bechtel National)

The Government Accountability Office has recommended that the Department of Energy put a hold on construction of its High-Level Waste Facility at the Hanford Site near Richland, Wash. The GAO said design and construction of the facility, part of Hanford’s Waste Treatment and Immobilization Plant, also known as the Vit Plant, should be paused until several actions are taken, including considering other alternatives for managing the site’s high-level radioactive liquid waste.

Hanford workers recently transferred three containers of nonradioactive test glass from the site’s WTP to the nearby Integrated Disposal Facility. (Photos: DOE)

According to the Department of Energy’s Office of Environmental Management, two contractors at its Hanford Site in Washington state have finished a first-time relay of test glass as the site prepares to vitrify—or immobilize in glass—millions of gallons of radioactive and chemical waste from its large underground tanks.

Video: Watch an “instant replay” of the test glass relay here.

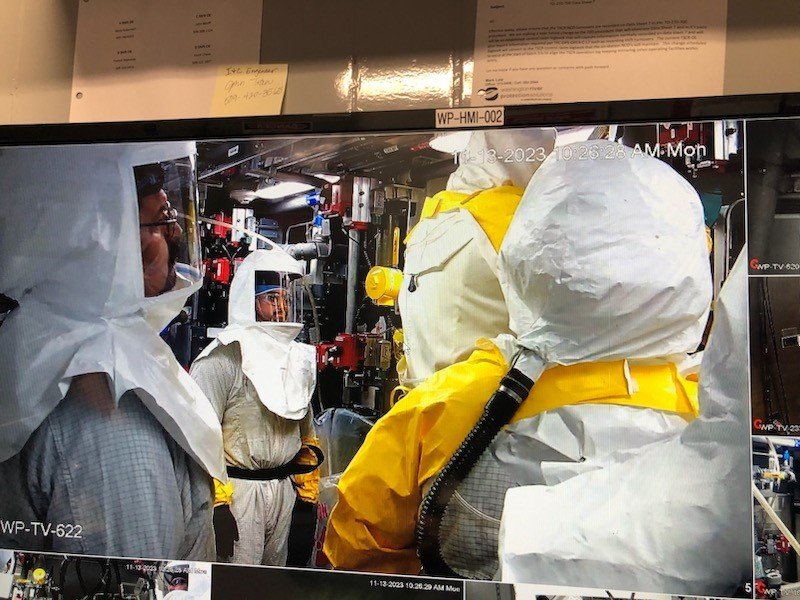

A monitor in the control room of the Hanford Site’s TSCR system shows workers performing maintenance inside the TSCR facility. (Photo: DOE)

The Department of Energy Office of Environmental Management’s Office of River Protection and contractor Washington River Protection Solutions have completed the first waste processing campaign through the Tank-Side Cesium Removal (TSCR) system at the Hanford Site.

A view of the Low-Activity Waste Facility at the Hanford Site. (Photo: DOE)

The National Academies of Sciences, Engineering and Medicine (NASEM) recently held a public meeting to discuss its third and final report centered on the Department of Energy’s Office of Environmental Management’s tank waste cleanup mission at the Hanford Site in Washington state.

Jared Wicker of SRNS explains how different technologies are used to monitor the environment at SRS. (Photo: DOE)

Claflin University students recently toured the Department of Energy’s Savannah River Site in South Carolina to learn about the facilities and occupations there.

Using GeoMelt ICV technology to treat and immobilize problematic low-level wastes at INL and WCS.

A sample of GeoMelt glass. (Photos: Veolia)

When it comes to managing nuclear waste, technology is transforming the way some of the most problematic waste is handled. The idea to transform nuclear waste into glass was developed back in the 1970s as a way to lock away the waste’s radioactive elements and prevent them from escaping. For more than 40 years, vitrification has been used for the immobilization of high-level radioactive waste in many countries around the world, including the United States.

Nicholas Callihan, left, and Julissa Quinonez Chavez, front, complete training to become qualified as control room supervisor and utilities operator for the Waste Treatment and Immobilization Plant. (Photo: DOE)

The DOE recently completed startup testing on the uninterruptable electrical power system for Hanford’s Low-Activity Waste Facility.

Department of Energy workers recently finished startup testing of a battery-powered backup electrical system for the Low-Activity Waste (LAW) Facility at the Hanford Site near Richland, Wash. According to the DOE’s Office of Environmental Management (EM), the uninterruptable electrical power system is vital to safeguarding the facility, part of Hanford’s Waste Treatment and Immobilization Plant, in the unlikely event of a temporary power loss to the plant.