The American Nuclear Society wrote to Congress, urging the need for a domestic supply of high-assay, low-enriched uranium.

September 15, 2021, 3:42PMUpdated September 15, 2021, 3:43PMPress Releases The United States Congress needs to take swift action to build a domestic supply of fuel for advanced reactors and to avoid future dependence on Russia for advanced nuclear fuel, the American Nuclear Society wrote in a Sept. 14 letter to the U.S. Senate Energy and Natural Resources Committee.

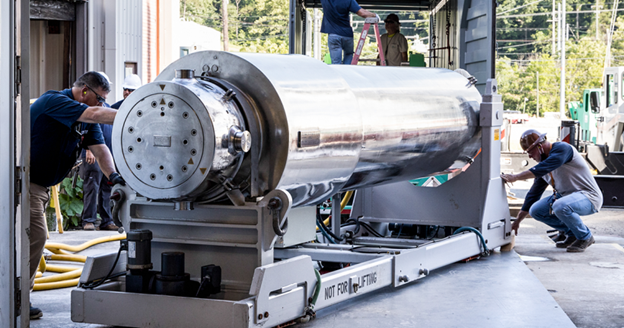

Irradiated lead test rods are delivered to Oak Ridge National Laboratory for examination. (Photo: ORNL)

Several lead test rods of Westinghouse’s EnCore accident tolerant fuel recently arrived at Oak Ridge National Laboratory for post-irradiation examination over the next year in support of the Nuclear Regulatory Commission’s licensing process. The rods were installed in 2019 in Exelon’s Byron-2, a 1,158-MWe pressurized water reactor, and were removed in fall 2020 and prepared for shipment to ORNL.

The Taishan nuclear power plant, in China’s Guangdong Province. Photo: EDF Group

Unit 1 at the Taishan nuclear power plant in China has been shut down to examine fuel rod damage and conduct maintenance, China General Nuclear Power Group (CGN) reported last Friday.

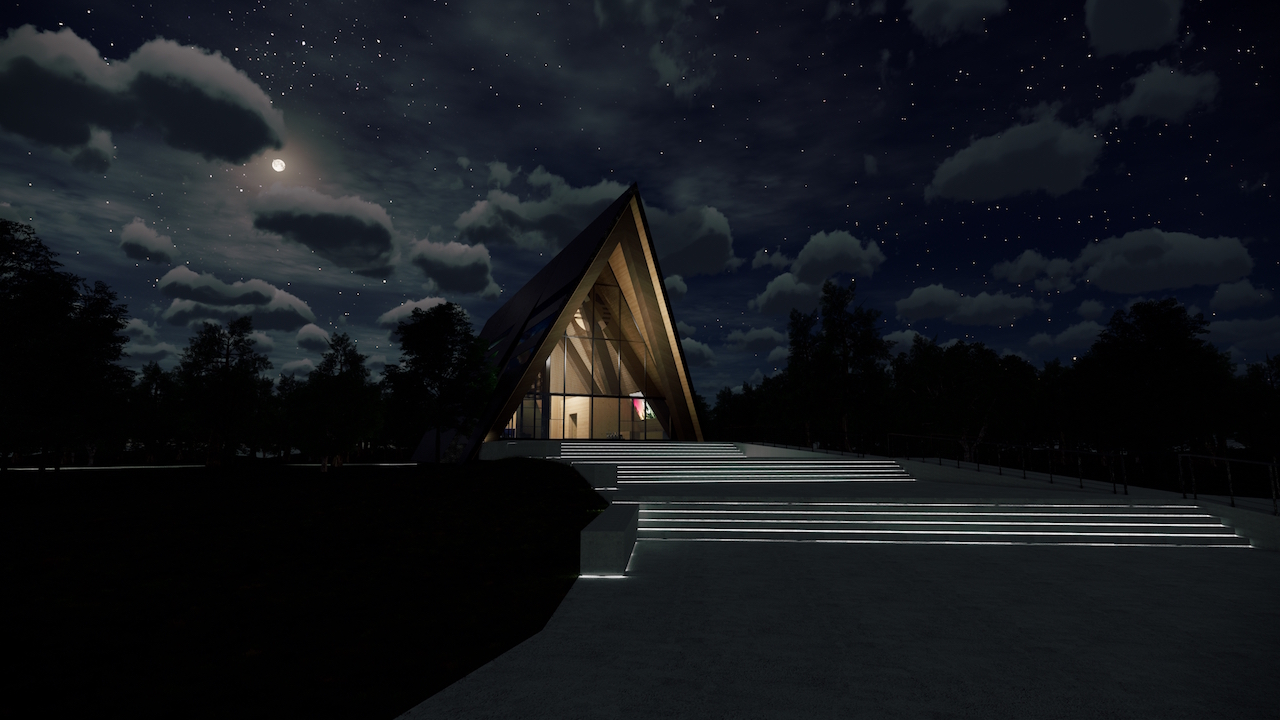

An artist's rendition of Oklo’s Aurora powerhouse. (Image: Gensler)

California-based Oklo has received a $2 million cost-share award from the Department of Energy for the commercialization of advanced fuel recycling capabilities by using electrorefining technology. Oklo is matching $1 million in funds and is partnering with the DOE and Argonne National Laboratory on this public-private partnership, which is intended to help reduce fuel costs for advanced reactor designs while reducing waste by turning used fuel into advanced reactor fuel.

Centrus’s American Centrifuge Plant, in Piketon, Ohio. Photo: Centrus Energy

Centrus Energy Corporation has announced that the Nuclear Regulatory Commission approved the company’s license amendment request to produce high-assay low-enriched uranium at its Piketon, Ohio, enrichment facility. The Piketon plant is now the only U.S. facility licensed to enrich uranium up to 20 percent uranium-235, and it is expected to begin demonstrating HALEU production early next year, according to Centrus.

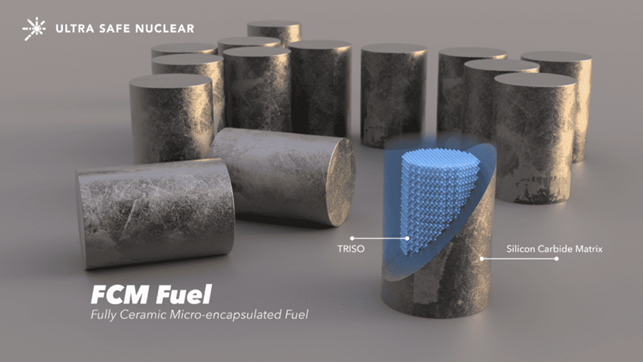

Fully ceramic microencapsulated fuel. Image: USNC

Canadian Nuclear Laboratories (CNL) announced last week that it has fabricated fully ceramic microencapsulated (FCM) fuel pellets, a proprietary reactor fuel designed by Ultra Safe Nuclear Corporation (USNC) for its Micro Modular Reactor (MMR). The FCM project, funded through the Canadian Nuclear Research Initiative (CNRI), represents the first time that tristructural isotropic (TRISO) fuel has been manufactured in Canada, according to CNL.

Miners depart Niger’s Akouta uranium mine for the last time after production ended for good. Photo: Cominak

The Akouta mine in Niger stopped production on March 31 after 43 years of service and 75,000 metric tons of uranium extracted. Akouta, the largest underground uranium mine in the world, was operated by Cominak, a subsidiary of Orano. The shutdown was decided by Cominak’s board of directors on October 23, 2019, in response to the depletion of the mine’s deposit.

The interior of the process building at the American Centrifuge Plant in Piketon, Ohio, where Centrus Energy plans to operate a HALEU demonstration cascade by June 2022. (Photo: Centrus Energy)

Advanced reactor cores are being designed for higher efficiencies and longer lifetimes, but to get there, they need high-assay low-enriched uranium (HALEU).

Enriched to between 5 and 19.75 percent fissile U-235, HALEU is packed with nuclear potential. It can be used as a feedstock for the demonstration of new fuel designs, from uranium alloys to ceramic pellets and liquid fuels. Those fuels can enable advanced reactor and microreactor demonstrations. Operating light-water reactors could potentially transition to HALEU uranium oxide fuels for extended operating cycles and improved plant economics.

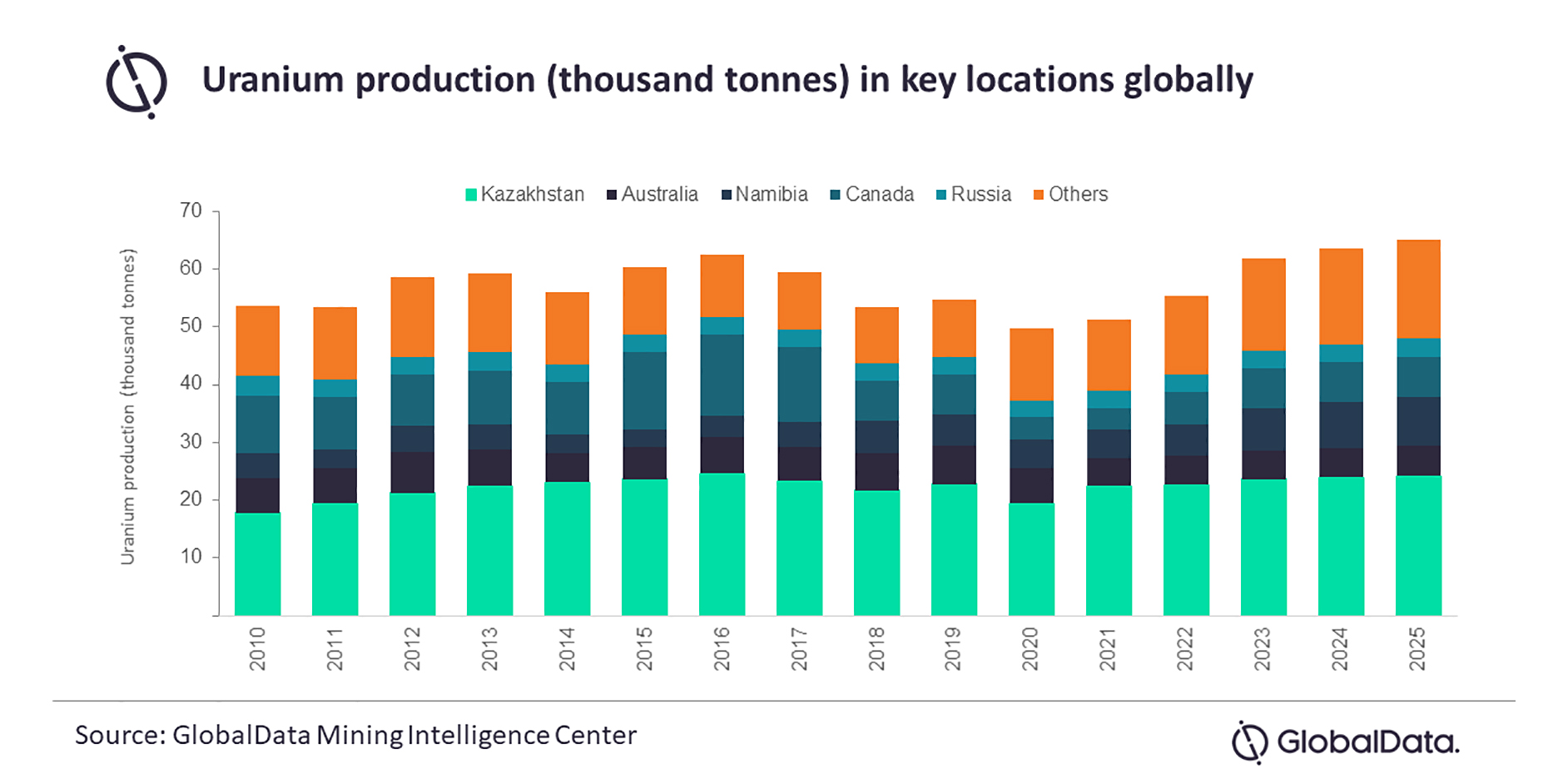

Adequate uranium resources exist to support the long-term, sustainable use of nuclear energy for low-carbon electricity generation, as well as for other applications, including hydrogen production. That assessment is contained in the latest (28th) edition of

Adequate uranium resources exist to support the long-term, sustainable use of nuclear energy for low-carbon electricity generation, as well as for other applications, including hydrogen production. That assessment is contained in the latest (28th) edition of