From left: David Piccini, Ontario’s minister of environment, conservation, and parks; Mike Rencheck, president and CEO, Bruce Power; Tim Gitzel, president and CEO, Cameco; and Todd Smith, Ontario’s minister of energy. (Photo: Bruce Power)

Canadian firms Cameco and Bruce Power have announced a 10-year extension of their long-term exclusive nuclear fuel supply arrangements, securing power generation from the eight-unit 6,507-MWe Bruce nuclear plant through 2040.

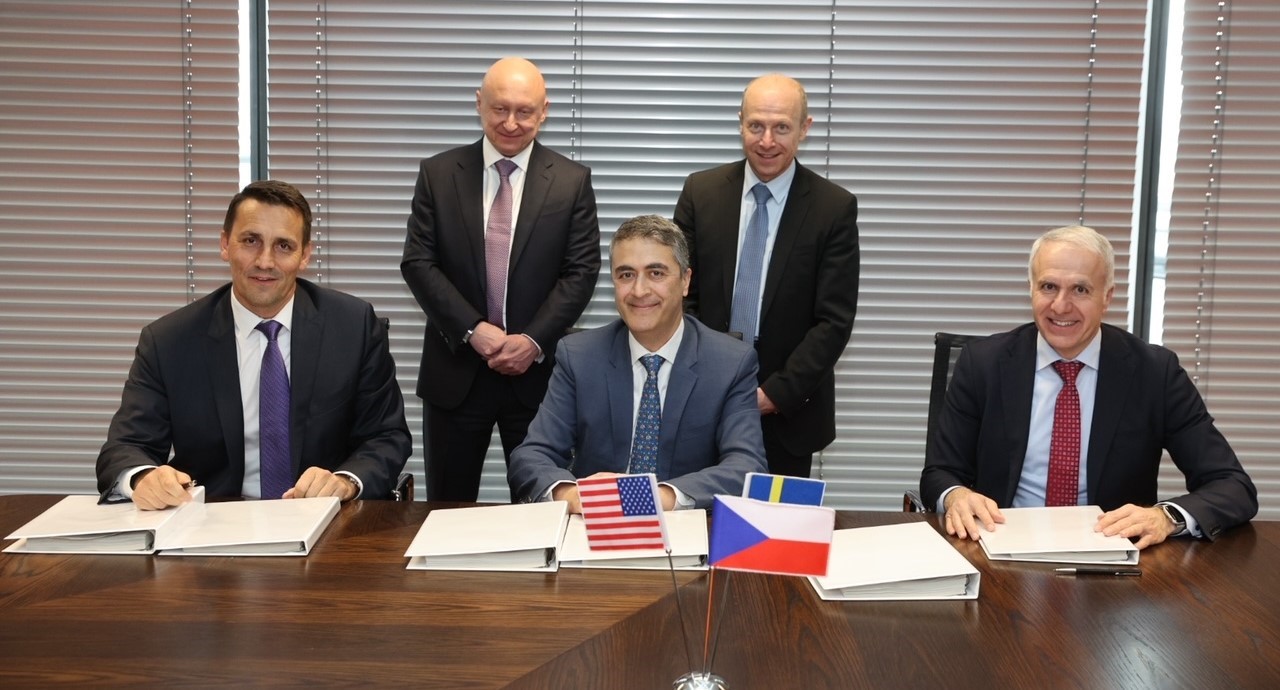

Bohdan Zronek, ČEZ board member and director of the firm’s nuclear energy division; Tarik Choho, president of Westinghouse’s nuclear fuel division; and Aziz Dag, senior vice president of BWR and VVER fuel for Westinghouse (seated, left to right) signed the agreement. Also present were David Benes, ČEZ Group CEO, and Patrick Fragman, Westinghouse CEO. (Photo: Westinghouse)

Westinghouse has signed an agreement with ČEZ, owner and operator of the Czech Republic’s nuclear power plants, to supply VVER-440 fuel assemblies to the Dukovany facility, the American firm announced March 29. Fuel deliveries will commence in 2024, replacing Russia’s TVEL fuel, with an anticipated term of seven years. One of the Czech Republic’s two nuclear power plants, Dukovany houses four Russian-supplied VVER-440/V213 reactors.

Mock-up of four-lobed helical fuel rods. (Photo: Lightbridge)

Lightbridge Corporation, which is continuing to work closely with national laboratories on the manufacture and testing of its metallic fuel rod designs for light water reactors, just announced the results of an investigation on the casting process for molten uranium and zirconium with Pacific Northwest National Laboratory under the Department of Energy’s Gateway for Accelerated Innovation in Nuclear (GAIN) program.

A view of the completed demo cascade. (Photo: Centrus)

Centrus Energy announced February 9 that it has finished assembling a cascade of uranium enrichment centrifuges and most of the associated support systems ahead of its contracted demonstration of high-assay low-enriched uranium (HALEU) production by the end of 2023. When the 16-machine cascade begins operating inside the Piketon, Ohio, American Centrifuge Plant, which has room for 11,520 machines, it will be the first new U.S.-technology based enrichment plant to begin production in 70 years.

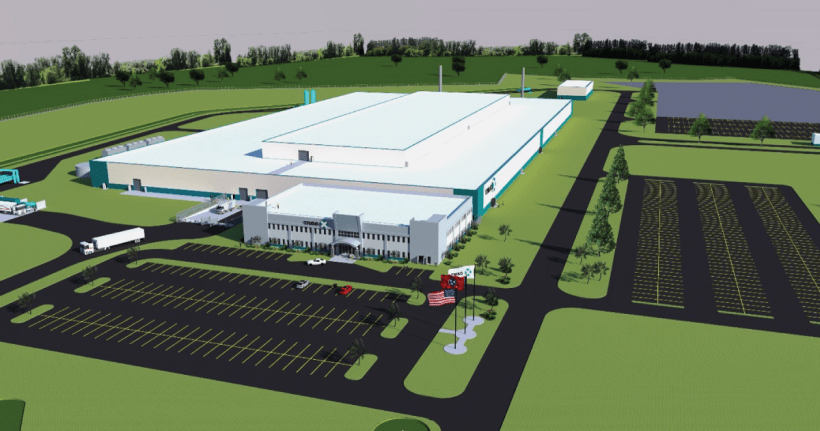

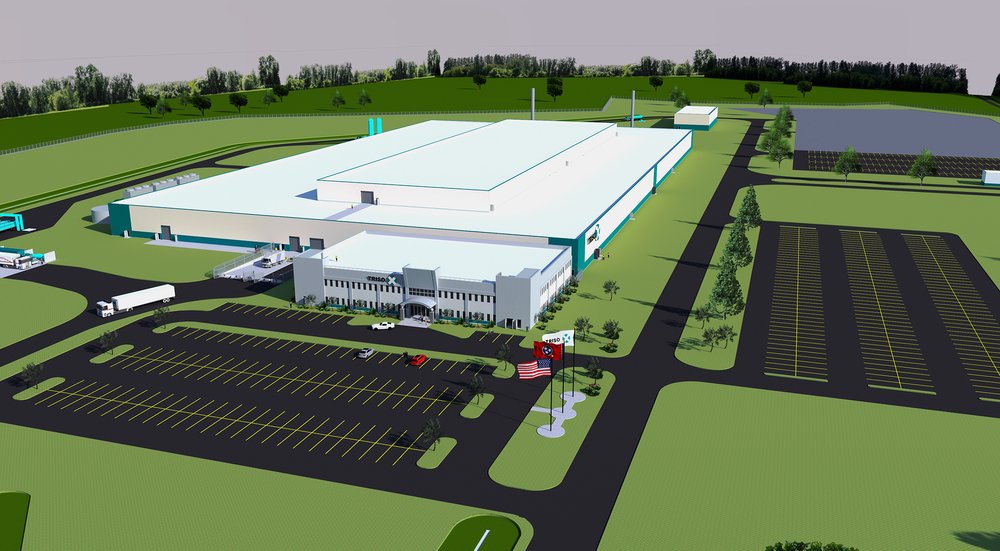

A rendering of the TRISO-X fuel fabrication facility. (Image: DOE)

The Nuclear Regulatory Commission recently presented its proposed 30-month licensing review timeline of TRISO-X’s planned fuel fabrication facility at the project’s first-ever public meeting in Oak Ridge, Tenn.

TRISO-X, a subsidiary of X-energy, has requested a 40-year license to possess and use special nuclear material to manufacture advanced fuel. The facility would be the first-ever commercial-scale fuel fabrication plant focused on using high-assay low-enriched uranium (HALEU).

Artist’s rendering of the proposed TRISO-X World Headquarters and Commercial Fuel Facility at the Horizon Center Industrial Park in Oak Ridge, Tenn. (Image: X-energy)

The Nuclear Regulatory Commission has accepted an application from X-energy's fuel subsidiary, TRISO-X LLC, for a proposed TRISO-X Fuel Fabrication Facility (TF3) in Oak Ridge, Tenn., X-energy announced last week. A 30-month review schedule has been developed by the NRC that would be completed by June 2025, assuming TRISO-X provides sufficient responses to expected requests for additional information (RAIs) within 30 to 60 days of their issuance. On December 16, the NRC announced that it would seek public input on the scope of its environmental review and environmental impact statement for the application and published a notice in the Federal Register.

These gas centrifuges operated in the Piketon facility from 2013 to 2016 as part of a 120-machine low-enriched uranium demonstration cascade. (Photo: Centrus Energy)

Centrus Energy confirmed on December 1 that its wholly owned subsidiary American Centrifuge Operating signed a contract with the Department of Energy, which was first announced on November 10, to complete and operate a demo-scale high-assay low-enriched uranium (HALEU) gaseous centrifuge cascade.

The TRIGA Mark II nuclear research reactor. (Photo: University of Texas)

The Nuclear Regulatory Commission has conducted a special inspection at the University of Texas’s TRIGA Mark II nuclear research reactor in Austin to evaluate the use of improper fuel. The inspection was ordered following a notification from the University of Texas—Austin to the NRC that the research reactor had been operating for several months with two fuel elements that were not licensed for the reactor.

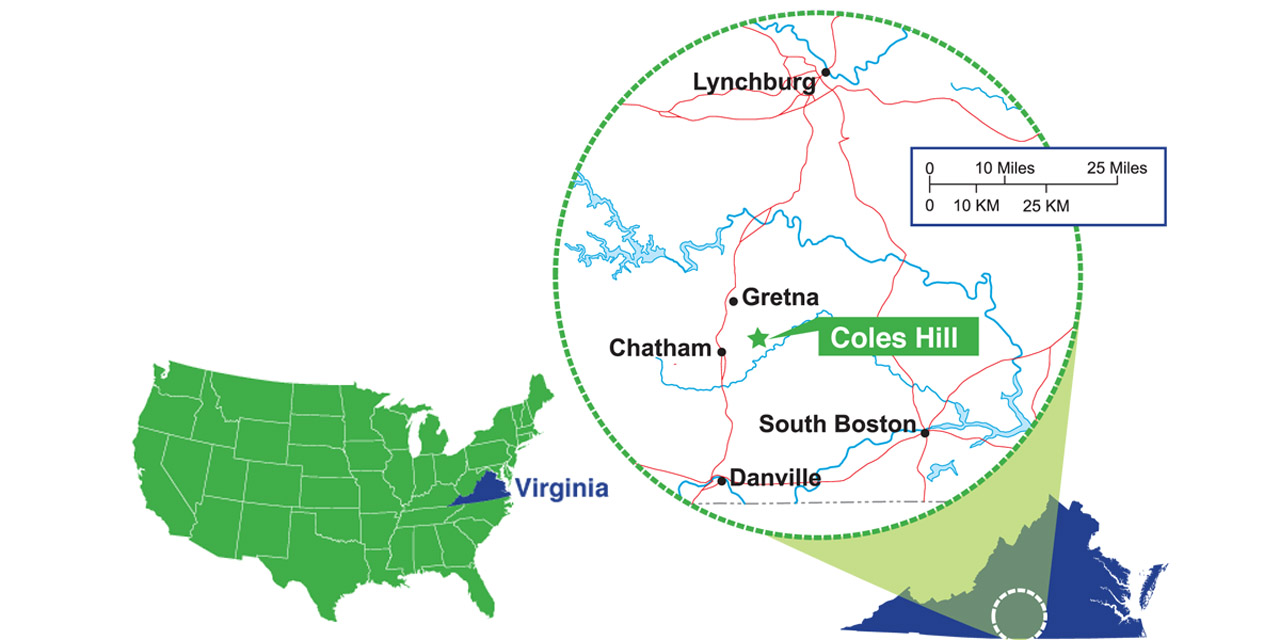

Coles Hill property location. (Image: Consolidated Uranium)

Consolidated Uranium plans to acquire Virginia Energy Resources, which owns Virginia Uranium and the Coles Hill Uranium Project, an undeveloped uranium deposit that sits under about 3,000 acres of land in south central Virginia. The state’s General Assembly has maintained a moratorium on uranium mining since 1982 that was upheld in the courts as recently as 2020, but Consolidated Uranium sees reason for “confidence that the moratorium on developing uranium projects in the state may ultimately be overcome,” and appears content to settle in for a wait.

Centrifuge casings arrive in Piketon, Ohio. (Photo: Centrus Energy)

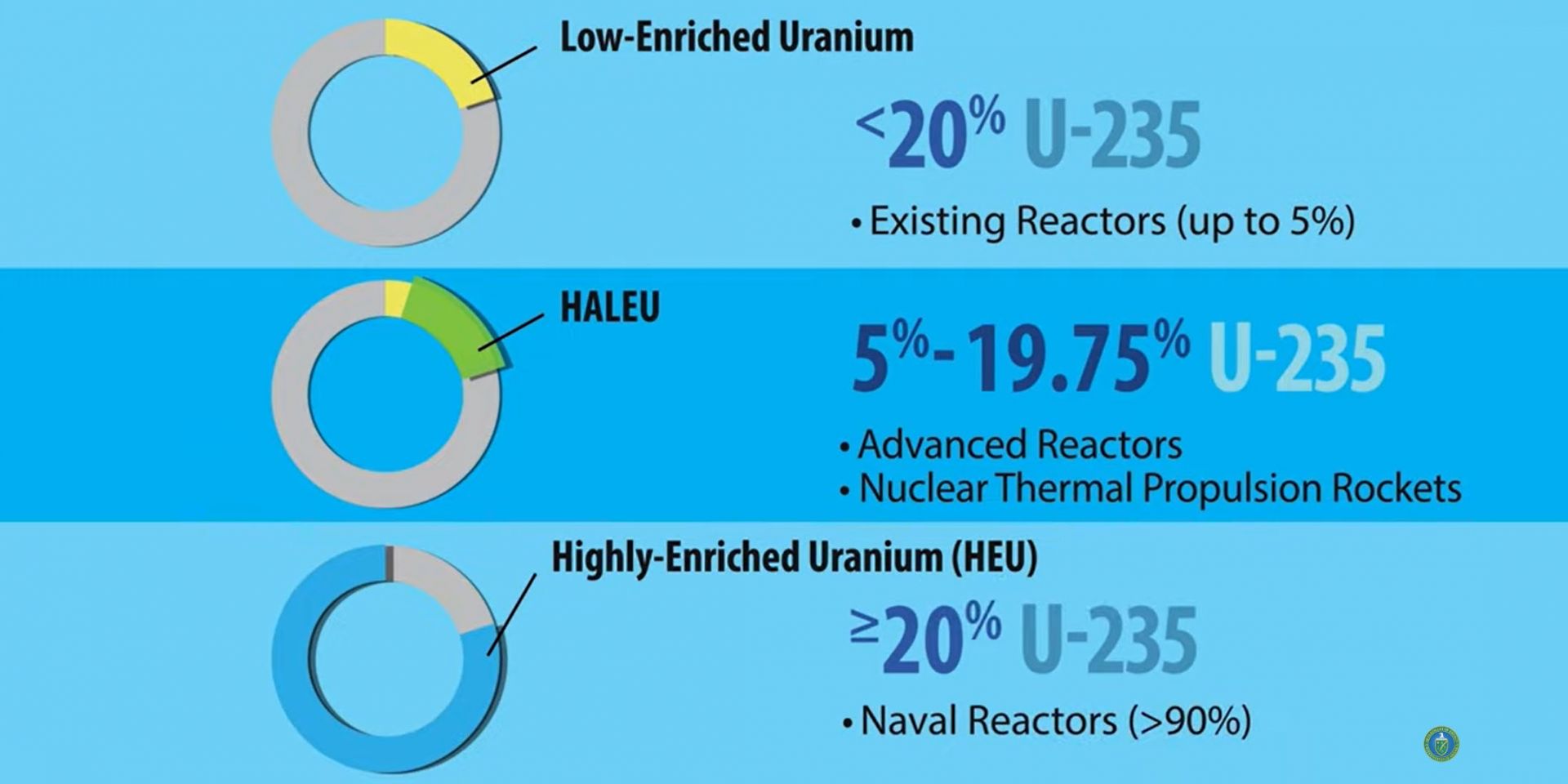

The Department of Energy announced a cost-shared award on November 10 valued at about $150 million for American Centrifuge Operating, a subsidiary of Centrus Energy, to complete the high-assay low-enriched uranium (HALEU) demonstration project it began in 2019. After delays that Centrus attributes in part to the COVID-19 pandemic, the company now has until the end of 2023 to produce the first 20 kilograms of HALEU enriched to 19.75 percent U-235 from the 16-centrifuge cascade it has installed in a DOE-owned Piketon, Ohio, facility—the only U.S. facility currently licensed to produce HALEU.

Framatome’s GAIA fuel assembly with Protect EATF technologies. (Photo: Framatome)

Framatome has completed the second 18-month cycle of its GAIA Protect Enhanced Accident Tolerant Fuel (EATF) technology at Vogtle’s Unit 2 in Waynesboro, Ga. Inspections afterward revealed that the full-length chromium-coated fuel rods maintained their original characteristics, while the chromia-enhanced pellets operated as designed during 36 months of reactor operation.

Natrium Fuel Facility groundbreaking. (Photo: GNF-A)

Global Nuclear Fuel–Americas (GNF-A) and TerraPower announced their plans to build a Natrium fuel fabrication facility next to GNF-A’s existing fuel plant near Wilmington, N.C, on October 21. While more than 50 years of fuel fabrication at the site have supported the boiling water reactor designs of GE (GNF-A’s majority owner) and GE Hitachi Nuclear Energy (GEH), the Natrium Fuel Facility will produce metallic high-assay low-enriched uranium (HALEU) fuel for the sodium fast reactor—Natrium—that TerraPower is developing with GEH.

An image from the video “What is High-Assay Low-Enriched Uranium (HALEU)?” released by the DOE in April 2020. (Source: DOE)

Another piece of the plan for meeting the urgent need for high-assay low-enriched uranium (HALEU) to fuel advanced reactor deployments fell into place when the Department of Energy held an Industry Day on October 14. Attendees were asked how soon they could deliver 25 metric tons per year of HALEU enriched in the United States from newly mined uranium. Offtake contracts for six or more years of HALEU production at that rate could be used to stock a DOE-owned HALEU bank to “support [HALEU] availability for civilian domestic research, development, demonstration, and commercial use.”