Building instrumentation and control technologies into the design of the next generation of advanced nuclear reactors will help the industry meet zero-carbon-emissions goals.

December 23, 2021, 3:00PMNuclear NewsAlexander Heifetz, Matthew Weathered, Nathan Hoyt, Mark Anderson, Scott Sanders, Anthonie Cilliers Kairos Power’s Instrumentation Test Unit

As a source of carbon-free electricity, nuclear energy currently dominates in the United States. However, the light water reactors in the U.S. are approaching the end of their licensed service lives. Meanwhile, low-cost electricity generated by fossil fuel–based sources (such as natural gas) poses an ongoing challenge to the economic viability of commercial nuclear reactors. To enhance the competitiveness of the nuclear industry, we need to bring down the high operating and maintenance (O&M) costs through savings available from utilizing modern, efficient sensing and automation technologies.

A cutaway view of a nuclear reactor. Its construction consists of two essential material types: fuel, which comprises the rods and cores that hold the fuel (center vertical bands); and structural, those parts of the reactor that house the fuel materials. (Graphic: Shutterstock/petrov-k)

Researchers from the Department of Energy’s Argonne National Laboratory are developing a “tool kit” based on artificial intelligence that will help better determine the properties of materials used in building a nuclear reactor.

The Summit supercomputer at Oak Ridge National Laboratory began operations in 2018. (Photo: ORNL)

The Department of Energy has announced $9.25 million for research into the behavior and properties of structural materials under molten salt reactor conditions through collaborations using the DOE’s high-performance supercomputers.

Coated uranium fuel kernels, as viewed through a glovebox. (Photo: BWXT)

Nuclear thermal propulsion (NTP) is one technology that could propel a spacecraft to Mars and back, using thermal energy from a reactor to heat an onboard hydrogen propellant. While NTP is not a new concept, fuels and reactor concepts that can withstand the extremely high temperatures and corrosive conditions experienced in the engine during spaceflight are being designed now.

BWX Technologies announced on December 13 that it has delivered coated reactor fuels to NASA for testing in support of the Space Technology Mission Directorate’s NTP project. BWXT is developing two fuel forms that could support a reactor ground demonstration by the late 2020s, as well as a third, more advanced and energy-dense fuel for potential future evaluation. BWXT has produced a videoof workers processing fuel kernels in a glovebox.

A screen shot from the “Research Reactors in Support of Advanced Reactor R&D” session at the 2021 ANS Winter Meeting and Technology Expo.

First-of-a-kind research reactors, demo reactors, and research facilities are being developed and sited on university campuses to support the broader deployment of advanced reactors. At the 2021 ANS Winter Meeting and Technology Expo, during a December 2 panel session titled “Research Reactors in Support of Advanced Reactor R&D,” several of these planned projects were discussed in detail—including a molten salt reactor in Texas and a high-temperature gas–cooled reactor in Illinois.

The session was sponsored by the Reactor Physics Division and organized and chaired by Pavel Tsvetkov, of Texas A&M University. A video of the session is available to registered Winter Meeting attendees.

Jamie Weaver with the neutron depth profiling instrument. (Photo: T. Barvitskie/NIST)

The newest generation of lithium-ion batteries now being developed uses thin-film, solid-state technology and could soon safely power cell phones, electric vehicles, laptops, and other devices. However, like all batteries, solid-state lithium-ion batteries have a drawback: Impedance—electrical resistance—can build up as batteries are discharged and recharged, limiting the flow of electric current.

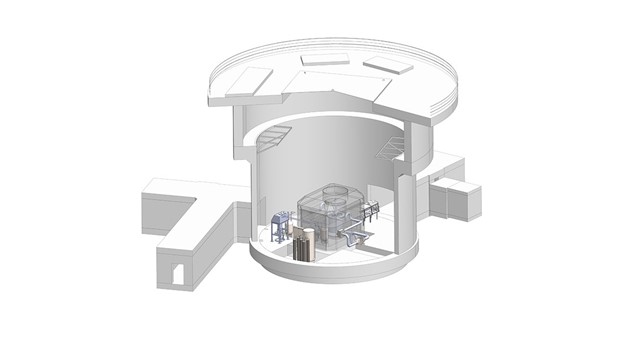

Artist's rendition of the Versatile Test Reactor. (Source: DOE)

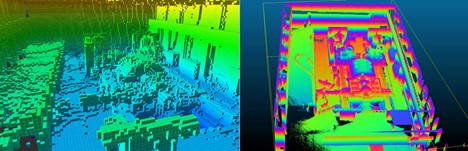

SwRI engineers used LIDAR point cloud data to reconstruct a high-resolution image of a facility that houses electric turbines at the nuclear power plant. 3D cubes, or voxels, on the left provide spatial information on the turbine facility. Point clouds were reconstructed to create the high-resolution image of the turbines on the right. SwRI specializes in data visualizations to identify damage and potential hazards following accidents at nuclear power plants and other hazardous facilities. (Graphic: SwRI)

During the EnRicH 2021 European Robotics Hackathon, Southwest Research Institute’s unmanned aircraft system (UAS or drone) explored and mapped the interior of a nuclear power plant, detecting radiation sources autonomously, without the aid of a human pilot.

SwRI’s UAS technology can potentially assist in life-saving search-and-rescue missions and hazardous inspections at industrial facilities and infrastructure following natural disasters and other incidents.

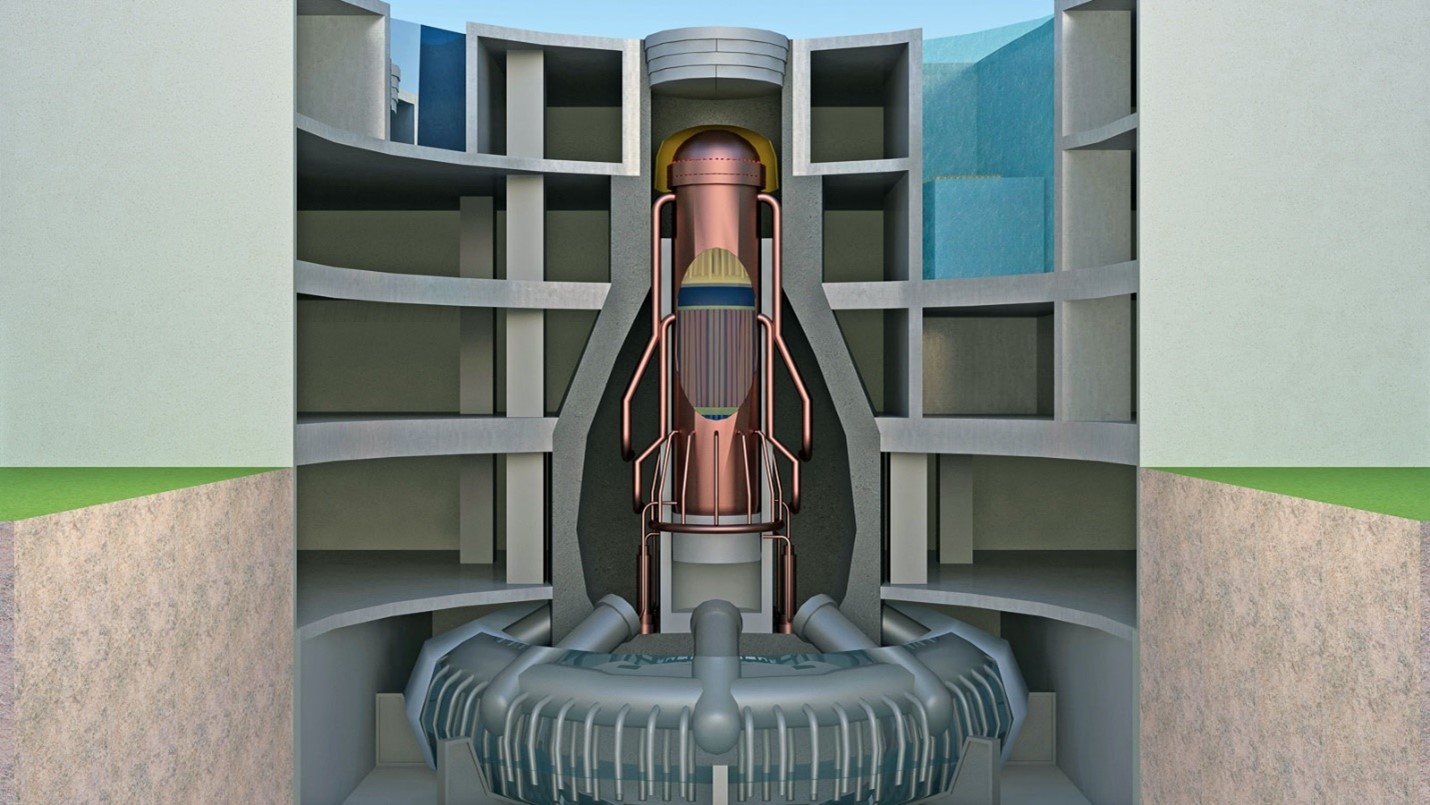

Artist’s concept of a fission surface power system on Mars. (Image: NASA)

NASA and Idaho National Laboratory have just opened a competitive solicitation for U.S. nuclear and space industry leaders to develop innovative technologies for a fission surface power system that could be deployed on the surface of the moon by the end of the decade. Battelle Energy Alliance, the managing and operating contractor for INL, issued a request for proposals and announced the news on November 19. Proposals are due February 17.

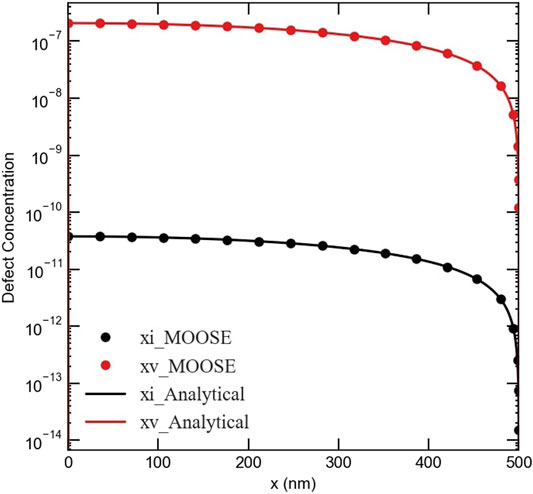

[CLICK IMAGE TO ENLARGE] A comparison between MOOSE results and the analytical solutions for the fractions of point defects in an irradiated spherical Ni grain with a 500 nm radius. The grain boundary/surface at x = 500 nm is assumed perfect and neutral. (Source: From Frontiers in Materials paper "Surface and Size Effects on the Behaviors of Point Defects in Irradiated Crystalline Solids")

By using a combination of physics-based modeling and advanced simulations, Texas A&M University researchers say they have found the key underlying factors that cause radiation damage to nuclear reactors, which could provide insight into designing more radiation-tolerant, high-performance materials.

The Molten Chloride Reactor Experiment will be built at Idaho National Laboratory to demonstrate criticality in a fast-spectrum salt-cooled reactor within five years. (Image: Southern Company)

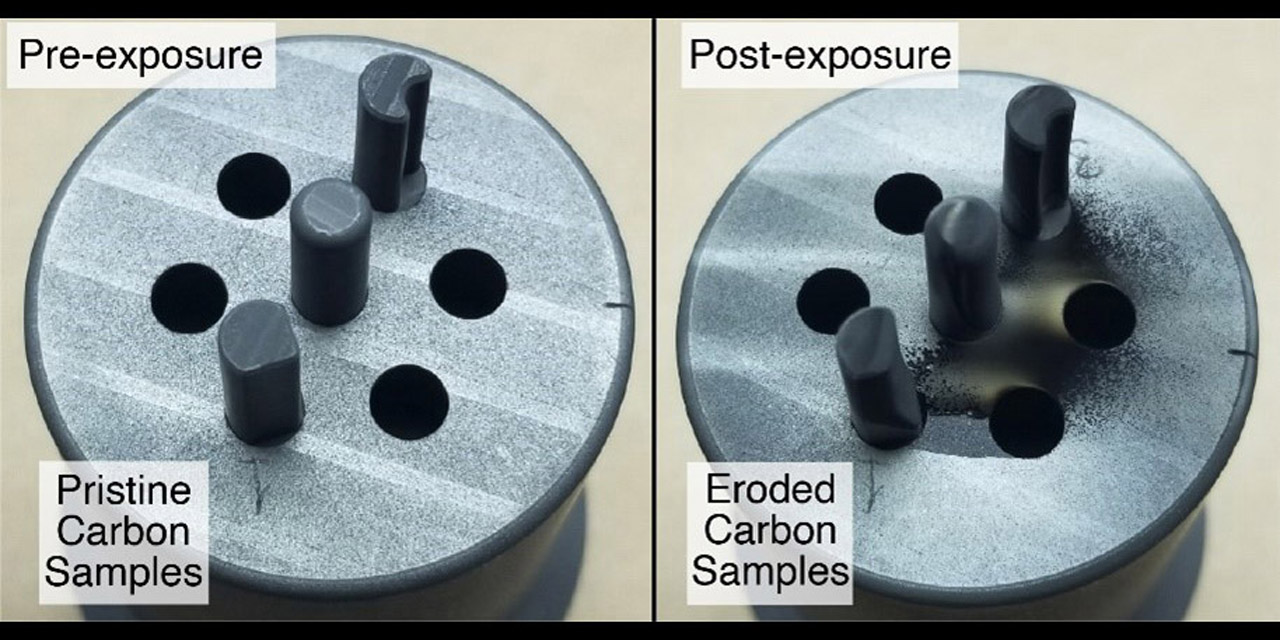

A set of graphite rods was exposed to hot plasma in the DIII-D tokamak. Researchers measured the ablation behavior under extreme heat and particle flow to simulate conditions experienced by spacecraft heat shields during atmospheric entry. (Image: General Atomics)

As a spacecraft on a research mission hurtles at up to 100,000 miles per hour toward the surface of a gas giant like Jupiter, the atmospheric gases surrounding the spacecraft turn to plasma, and spacecraft temperatures increase to more than 10,000 °F.

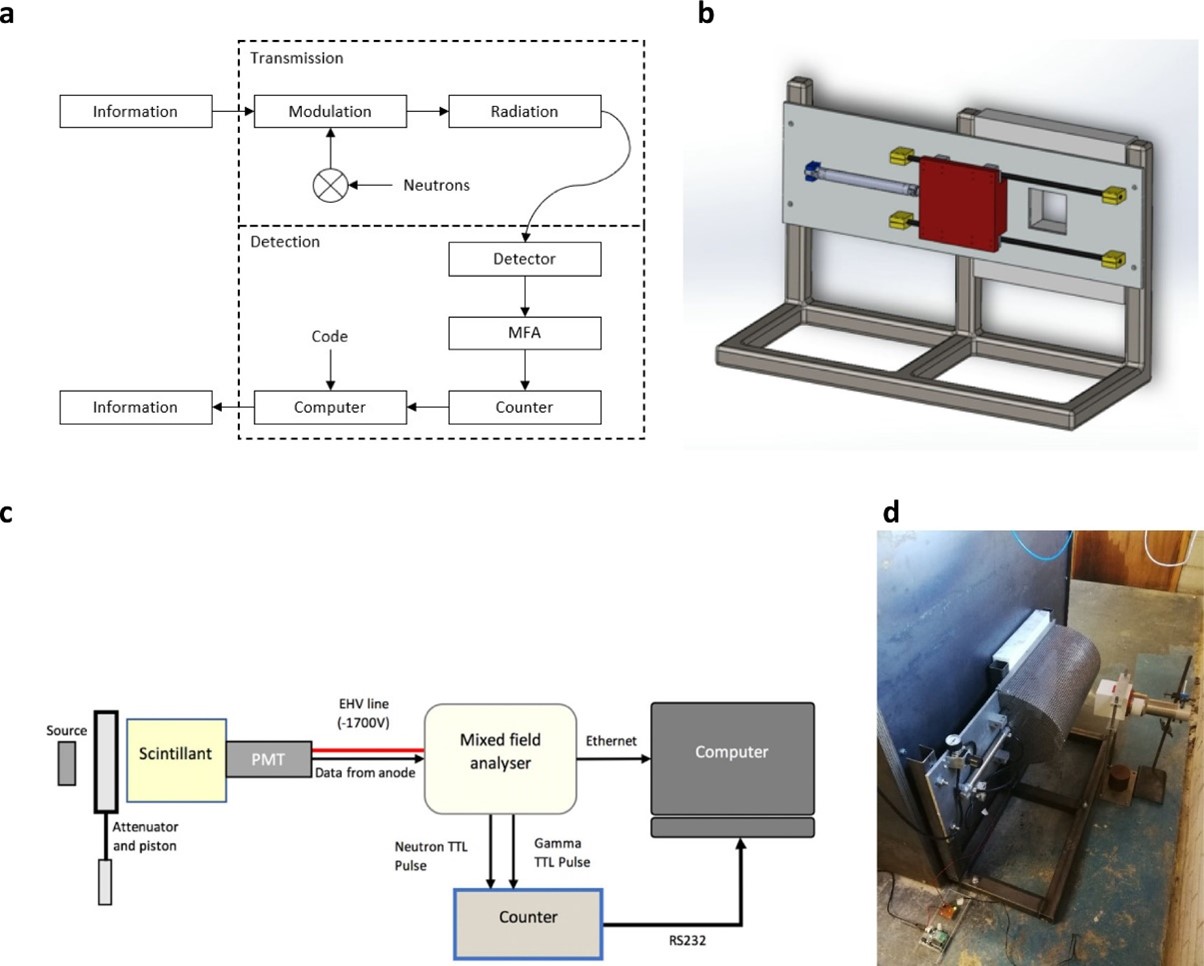

(CLICK IMAGE TO ENLARGE) The researchers’ experimental layout is depicted here. In (b), the neutron chopper is depicted without the mesh guard shown in (d), a photograph of the experimental layout that includes the Cf-252 source tank at left. (Composite image: Joyce, et al., “Wireless information transfer with fast neutrons,” doi.org/10.1016/j.nima.2021.165946)

Swapping conventional electromagnetic radiation for fast neutrons, a team of research engineers at Lancaster University in the United Kingdom, working with the Jozef Stefan Institute of Slovenia, report that they have successfully transmitted digital information wirelessly using nuclear radiation. The researchers’ attempts to transmit words and numbers using standard ASCII code “were 100 percent successful,” according to a November 10 press release from Lancaster University. Their research will be published in an upcoming issue of Nuclear Instruments and Methods in Physics Research and is now available online.

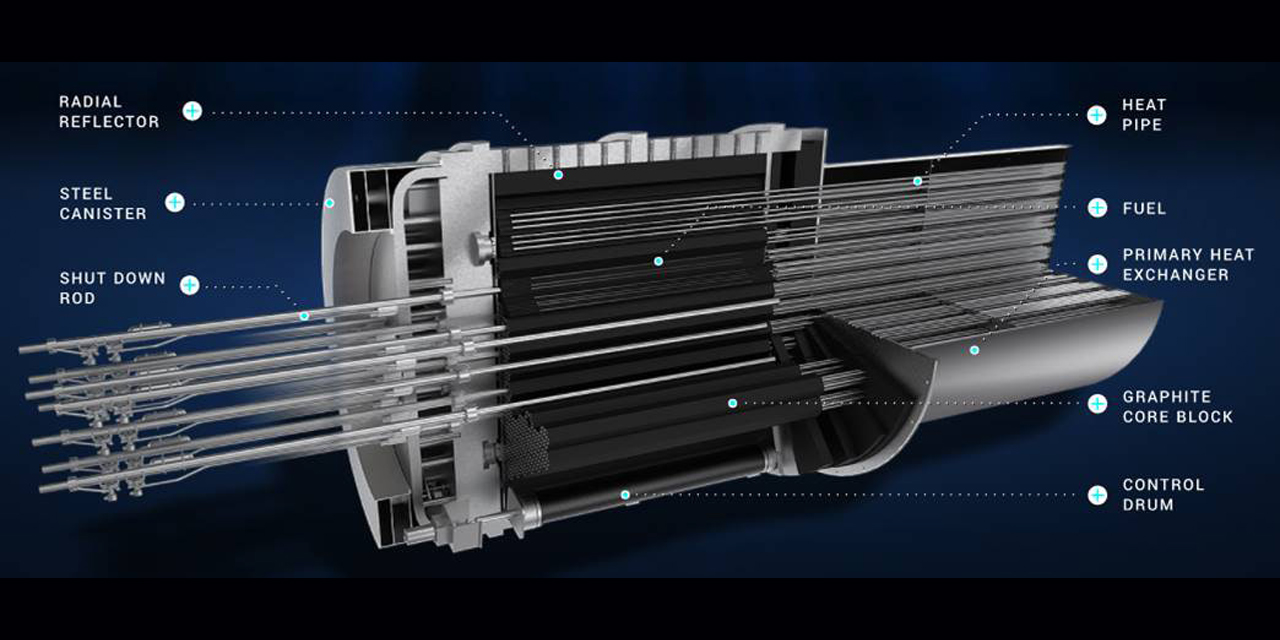

eVinci micro reactor core, (Illustration: Westinghouse)

A recently completed feasibility study by Westinghouse Electric Company and Bruce Power concludes that the eVinci microreactor is capable of providing cost-competitive clean energy to decentralized, off-grid markets in Canada.

A new study by researchers from Stanford University and the Massachusetts Institute of Technology—

A new study by researchers from Stanford University and the Massachusetts Institute of Technology—